Testing mechanism for battery charging and discharging equipment

A technology for charging and discharging equipment and testing institutions, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., which can solve the problems of adverse effects on the production of unfired batteries, low effective coverage rate, and large taper of nozzles, so as to reduce the amount of spray medium. Sputtering, improving spray uniformity and coverage, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

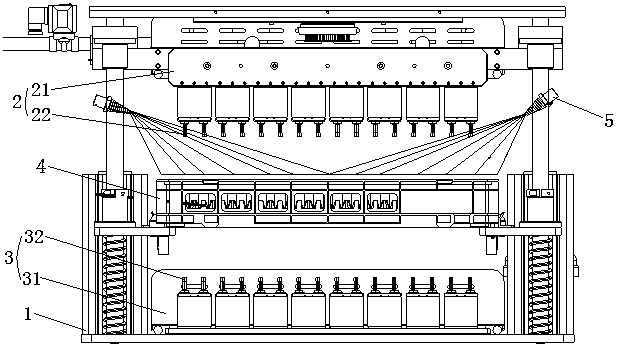

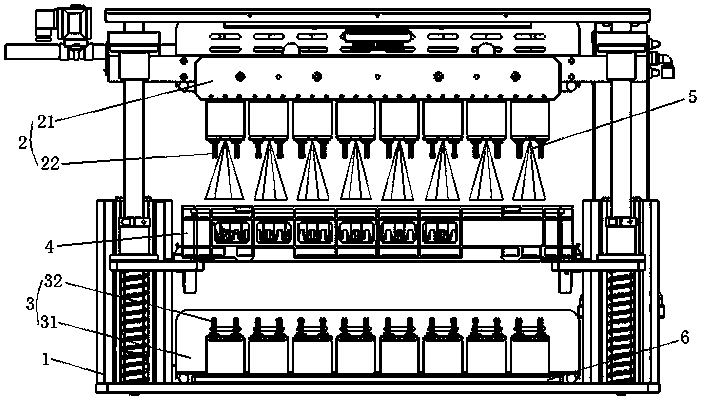

[0030] A kind of testing mechanism of battery charging and discharging equipment of the present embodiment, see figure 2 As shown, the testing mechanism includes a machine tool 1 , and an upper fixture module 2 , a lower fixture module 3 and a battery tray 4 arranged on the working table of the machine tool 1 . The test mechanism of this embodiment is suitable for charging and discharging tests of batteries, including circular or bar-shaped batteries, where the positive and negative tabs are far apart and the positive and negative tabs are not located on the same side.

[0031] Wherein, the battery tray 4 is used to hold the battery to be charged and discharged, and can move into the position between the upper clamp module 2 and the lower clamp module 3, or from the upper clamp module 2 and the lower clamp module 3. The position between the lower clamp modules 3 is moved out. When performing the battery charge and discharge test, the battery tray 4 loaded with the battery mo...

Embodiment 2

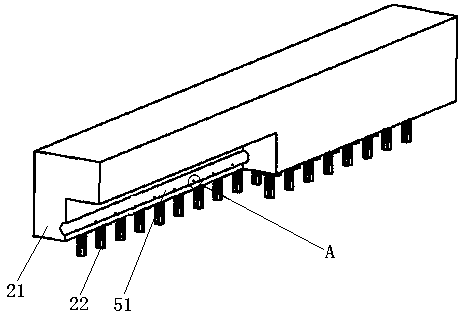

[0040] This embodiment is the same as Embodiment 1, further, see image 3 and Figure 4 As shown, in this embodiment, specifically, the fire sprinkler system 5 includes a fire-fighting pipeline 51 and a fire-fighting nozzle 52; the fire-fighting nozzle 52 communicates with the fire-fighting pipeline 51; the nozzle opening of the fire-fighting nozzle 52 Towards the lower fixture module 3 . Moreover, more specifically, the inlet of the fire-fighting pipeline 51 is provided with a fire-fighting medium pump with a valve group, and the valve group is servo-connected to the temperature and smoke detectors provided in the test station.

[0041] Moreover, the fire-fighting pipeline 51 is arranged in the upper clamp installation plate 21 . Specifically, in this embodiment, the fire-fighting pipeline 51 is a pipeline opened in the upper fixture installation plate 21, and the fire-fighting nozzle 52 is a through hole opened on the upper fixture installation plate 21 and communicated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com