Medical equipment sterilizing device

A technology for sterilization and sterilization of medical equipment, applied in heating devices, drying gas layout, chemical instruments and methods, etc., can solve the problems of large cleaning effect, waste of resources, low cleaning efficiency, etc., and achieve good cleaning quality and saving. Water resources, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

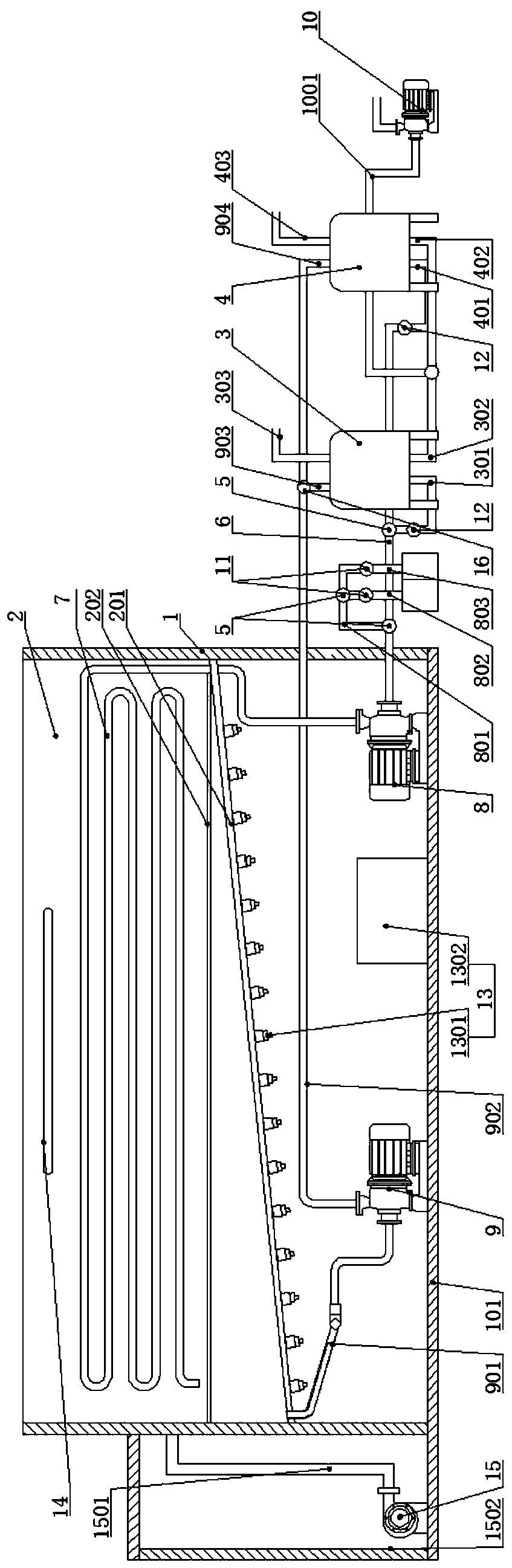

[0030] Such as figure 1As shown, a medical equipment disinfection and sterilization device includes a housing 1, a cleaning tank 2, a control system, and also includes a first filter 3 and a second filter 4. The outlet end of the first filter 3 is connected with The first pipeline 301, the outlet end of the second filter 4 is connected with the second pipeline 401, the first pipeline 301, the second pipeline 401 are connected with the third pipeline 6 through the tee 5, the third The pipeline 6 communicates with the main pipeline 7 through the tee 5, and the main pipeline 7 is connected with the outlet end of the filling pump 8, and the inlet end of the filling pump 8 is connected with the main pipeline 801 for adding fluid, and the main pipeline for adding fluid 801 is connected with a first liquid addition pipe 802 and a second liquid addition pipe 803 through a tee 5; the inlet ends of the first filter 3 and the second filter 4 are connected with the outlet end of the drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com