Die with telescopic handle mechanism

A mold and post-mold technology, applied in the field of molds with shrinking mechanism, can solve the problems of small application range, inability to apply telescopic molds, and inability to reduce the size of telescopic molds, and achieve high purity, uniformity, and excellent metallurgical quality , to meet the effect of normal production demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

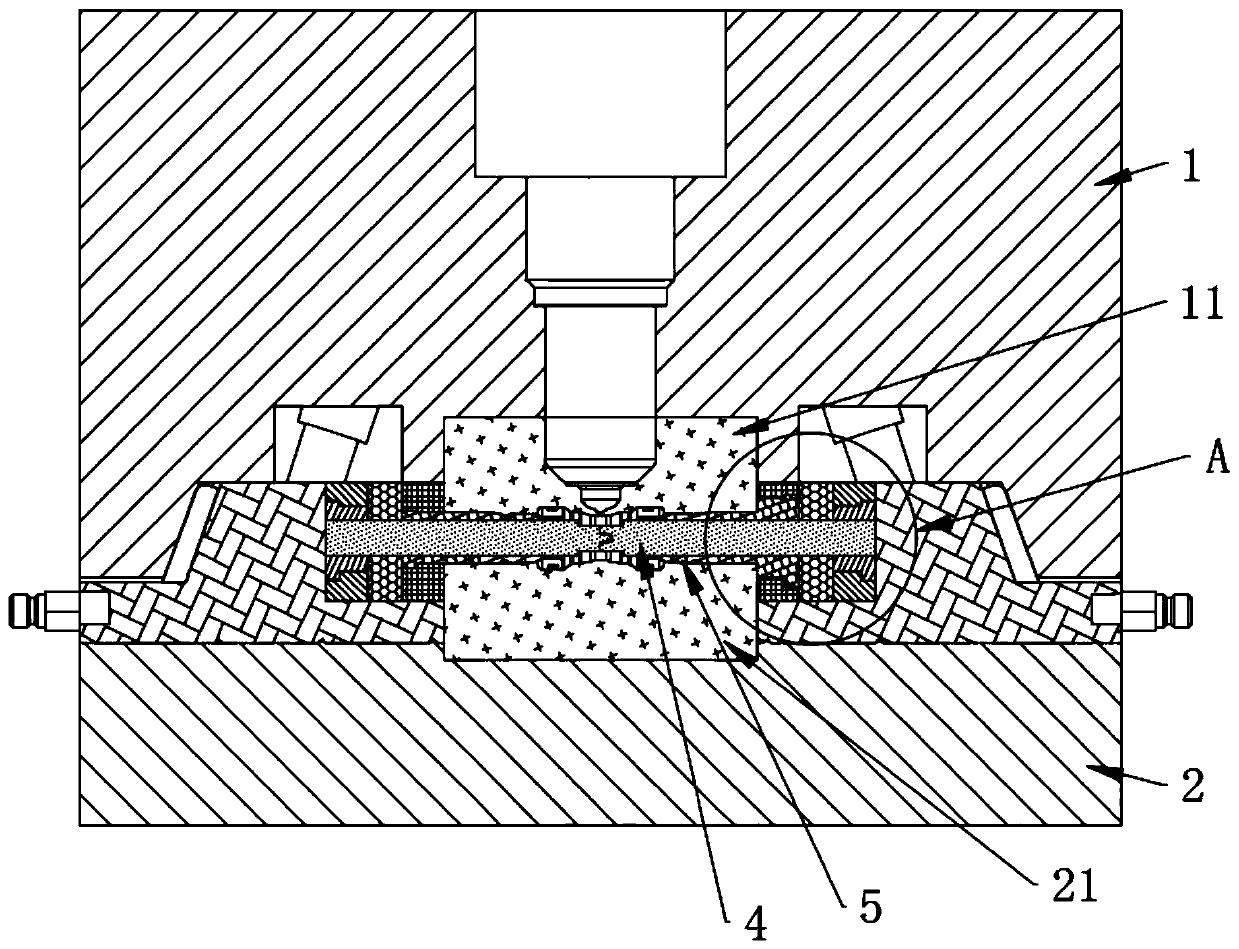

[0039] Embodiment: a kind of mold of band shrinkage mechanism, as figure 1 As shown, it includes a front mold 1 and a rear mold 2, the front mold 1 is provided with an upper cavity plate 11, the rear mold 2 is provided with a lower cavity plate 21, and the upper cavity plate 11 and the lower cavity plate 21 are closed to form a product The cavity of the external shape.

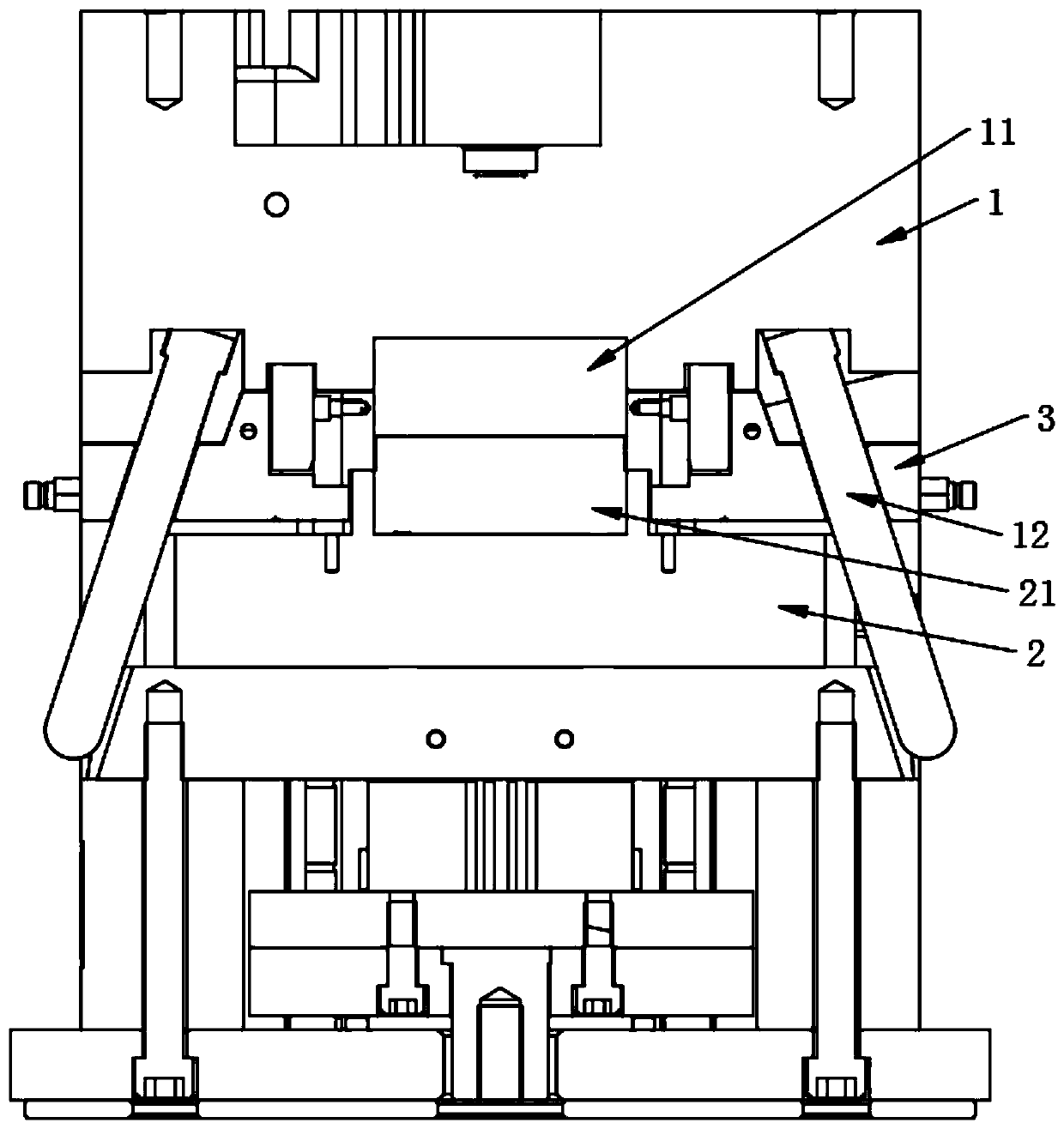

[0040] like figure 2 As shown, shrink parts are arranged between the front mold 1 and the rear mold 2, the shrink parts include the slider seat 3, the rear mold 2 is provided with a chute for the slider seat 3 to fit and slide, and the front mold 1 is set There is an inclined guide post 12 passing through the slider seat 3. When the front mold 1 moves relative to the rear mold 2, the slider seat 3 will slide under the promotion of the inclined guide post 12.

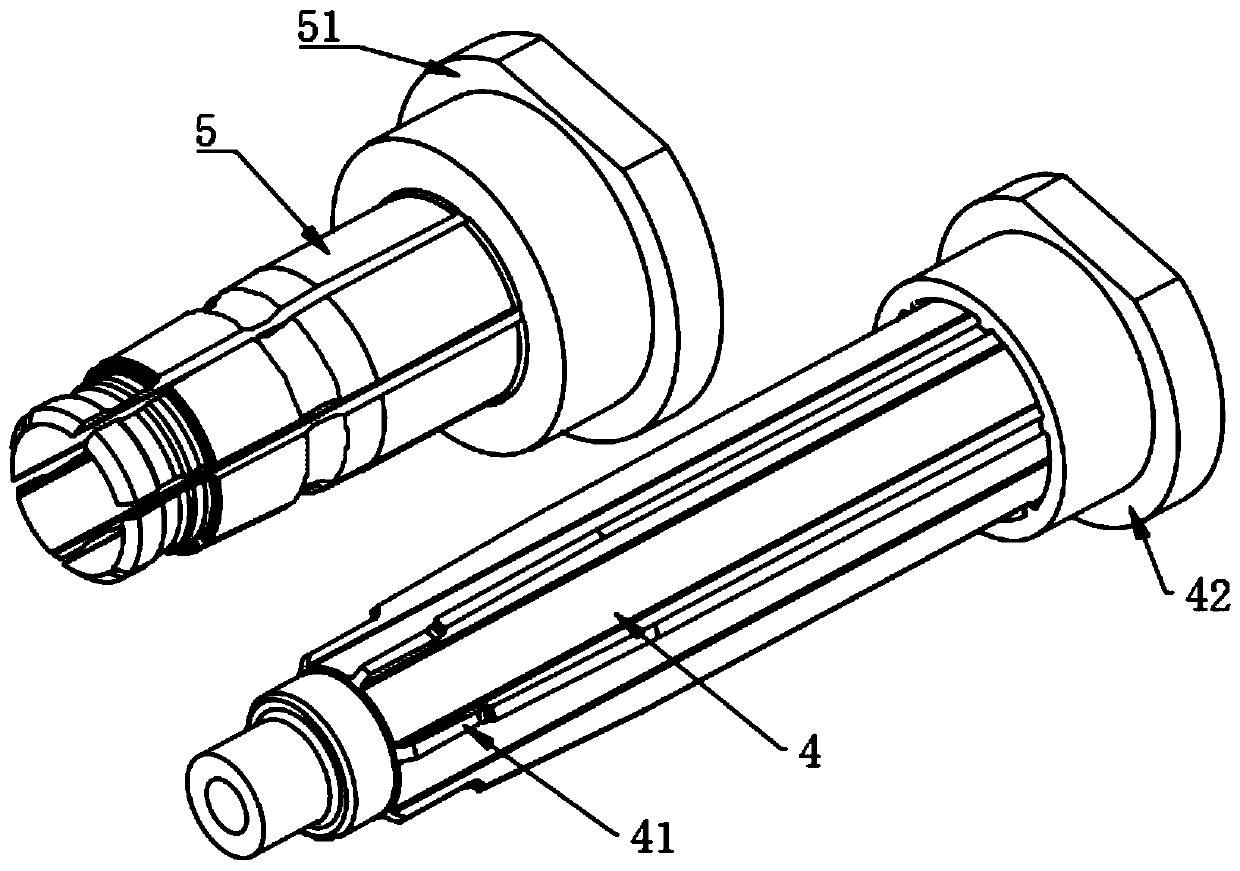

[0041] like figure 1 As shown, the shrinkage part is provided with a slider insert 4 inserted into the cavity and a plurality of undercut inserts 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com