Automatic tearing and adhering type double faced adhesive tape forming device for box cover

A technology of forming equipment and double-sided adhesive tape, which is used in box making operations, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as inability to meet production needs, low production efficiency, and difficult quality assurance, and improve equipment utilization. , saving labor, and the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

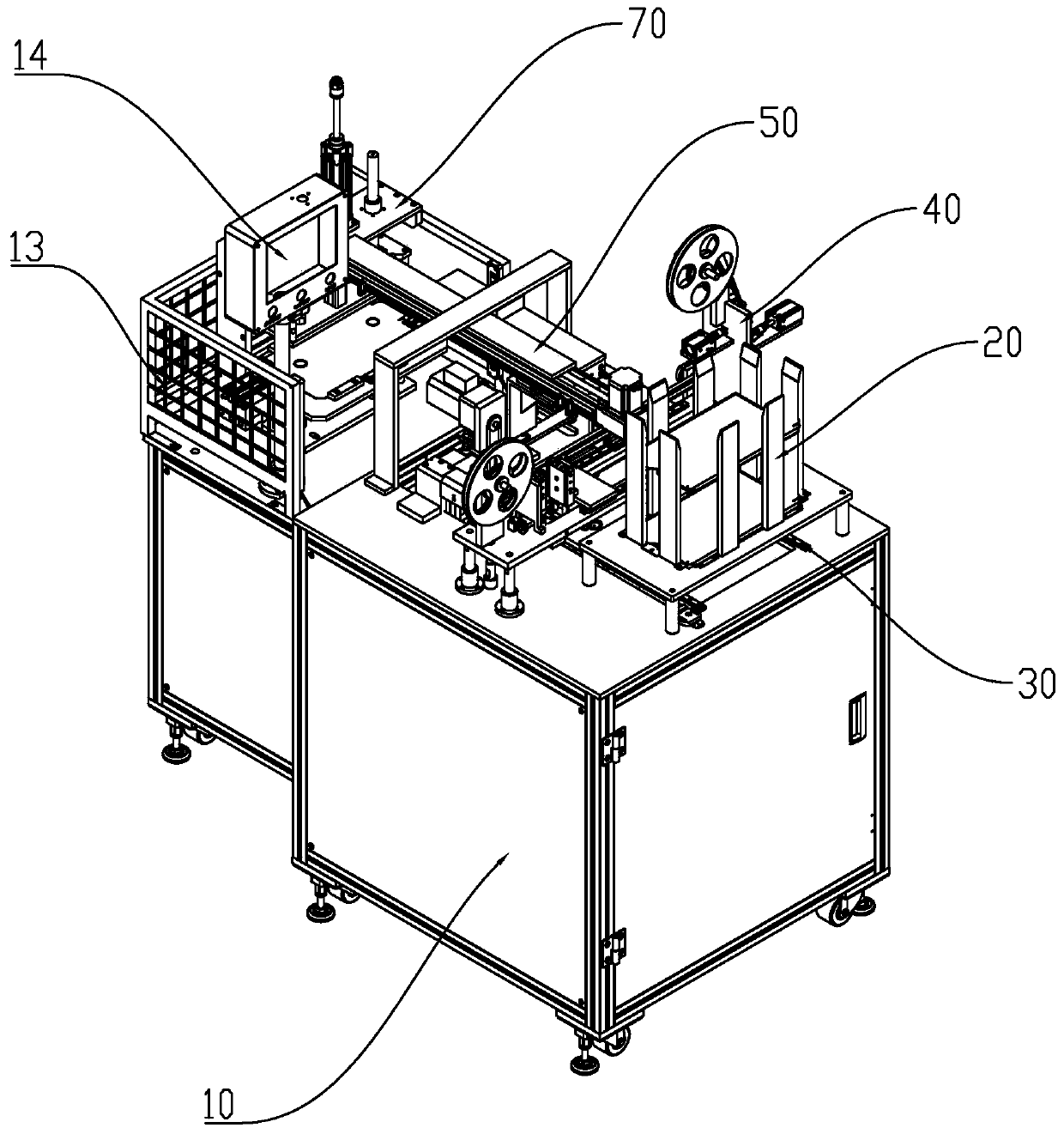

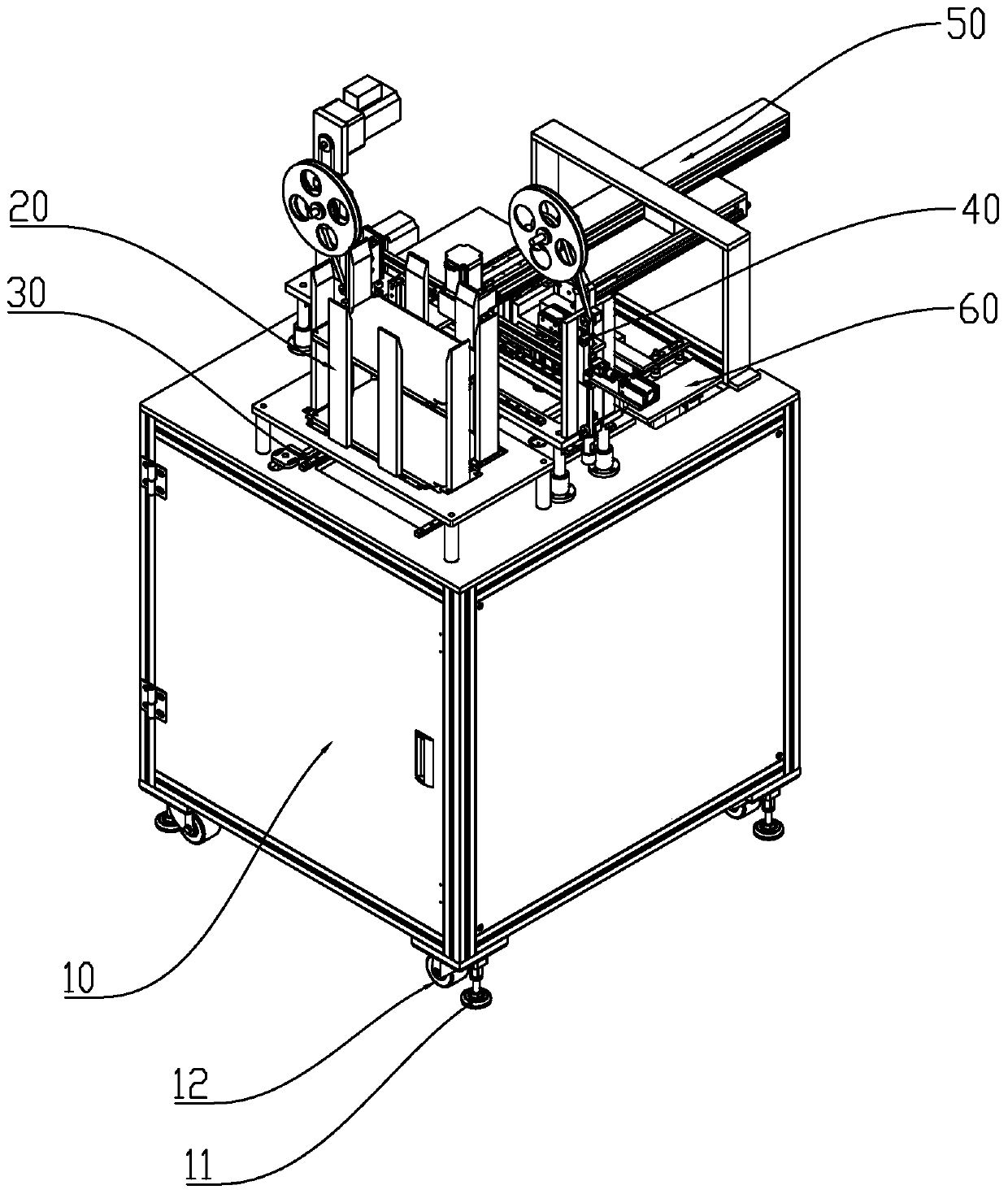

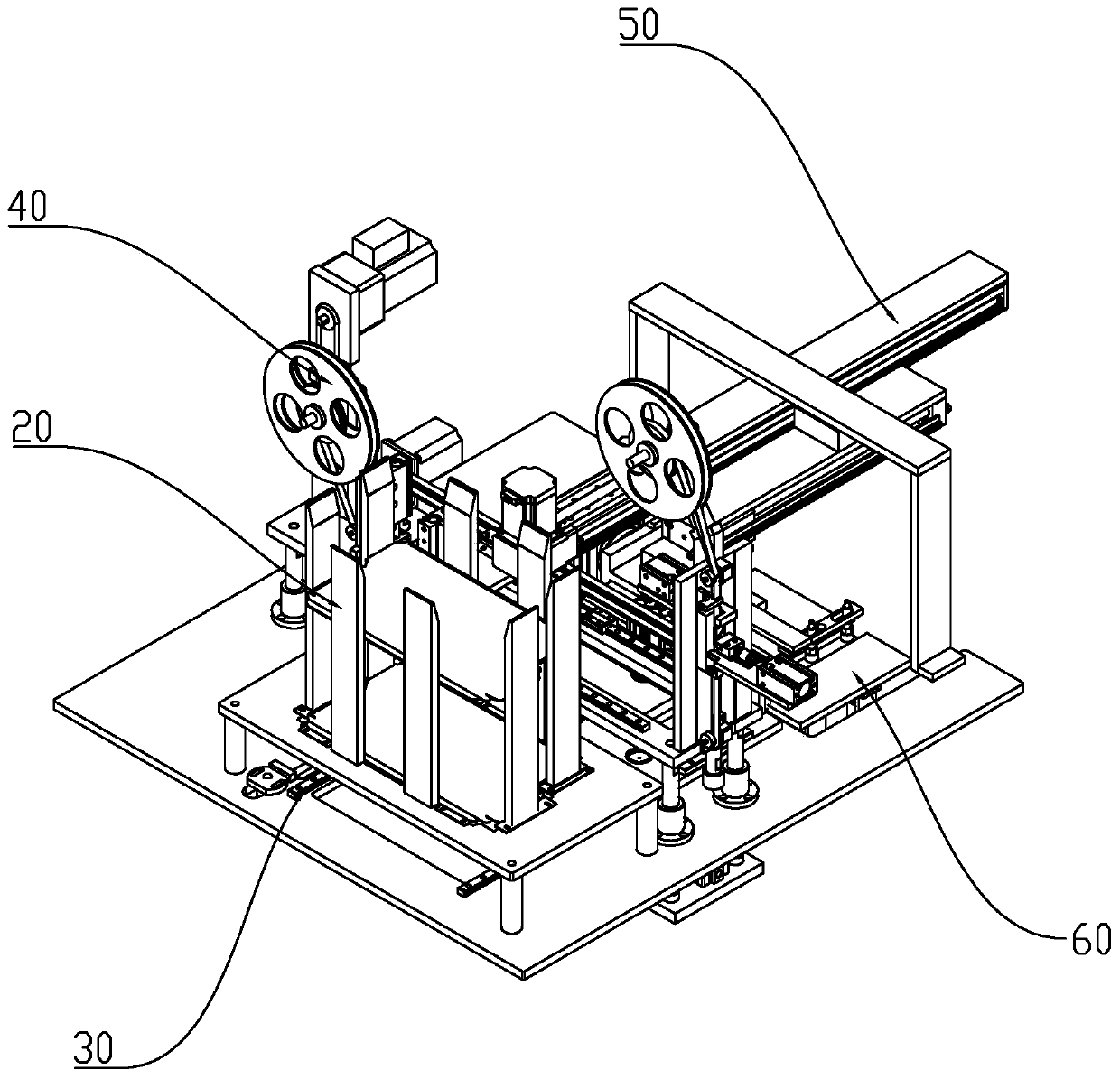

[0035] Such as Figure 1 to Figure 17 As shown in the specific embodiment, the present invention discloses a box cover automatic tearing and sticking double-sided adhesive molding equipment, including a frame 10, a trough assembly 20 arranged on one side of the frame 10, and a trough assembly 20 arranged on the trough The retrieving and positioning assembly 30 and the tearing and sticking glue mechanism 40 at the rear end of the assembly 20, the transplanting assembly 50 located at the rear end of the tearing and sticking glue mechanism 40, the rotating assembly 60 located on one side of the transplanting assembly 50, and the Describe the molding mechanism 70 at the rear end of the transplanting assembly 50.

[0036] Specifically, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com