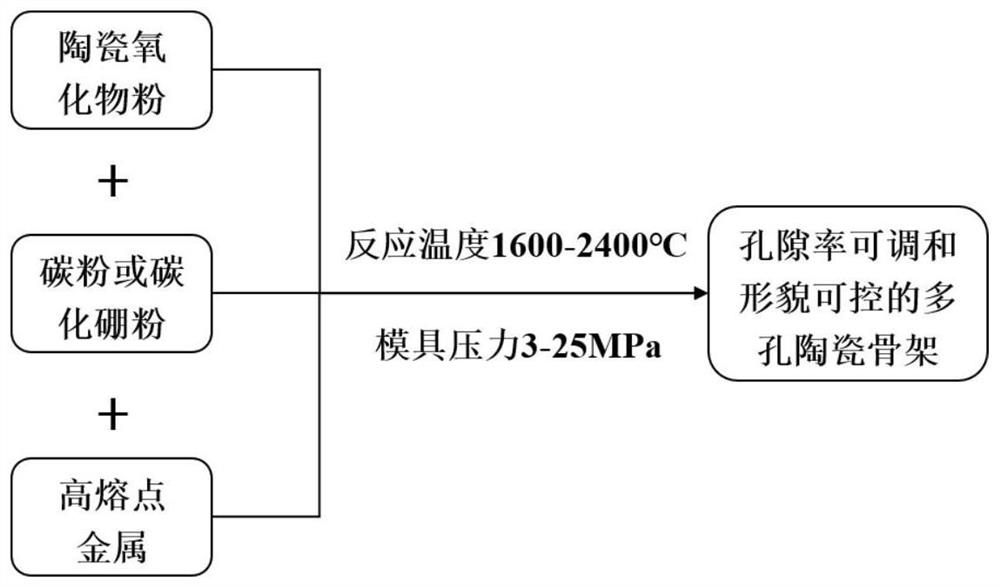

A preparation method of ultra-high temperature porous ceramic framework with controllable morphology

A porous ceramic and ultra-high temperature technology, which is applied in the field of preparation of ultra-high temperature porous ceramic skeleton with controllable morphology, can solve the problems of difficult control of pores, low mechanical strength, and unsatisfactory precision of porous materials, so as to reduce wettability, Improves mechanical strength and facilitates the effect of catalyst enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

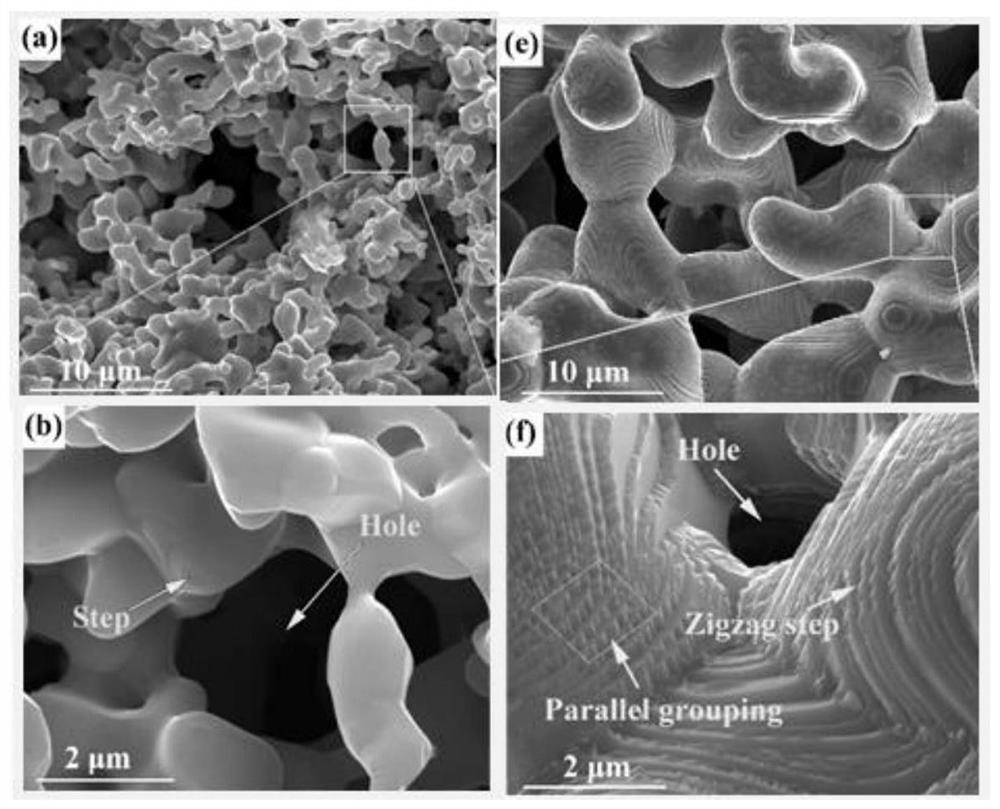

Examples

Embodiment 1

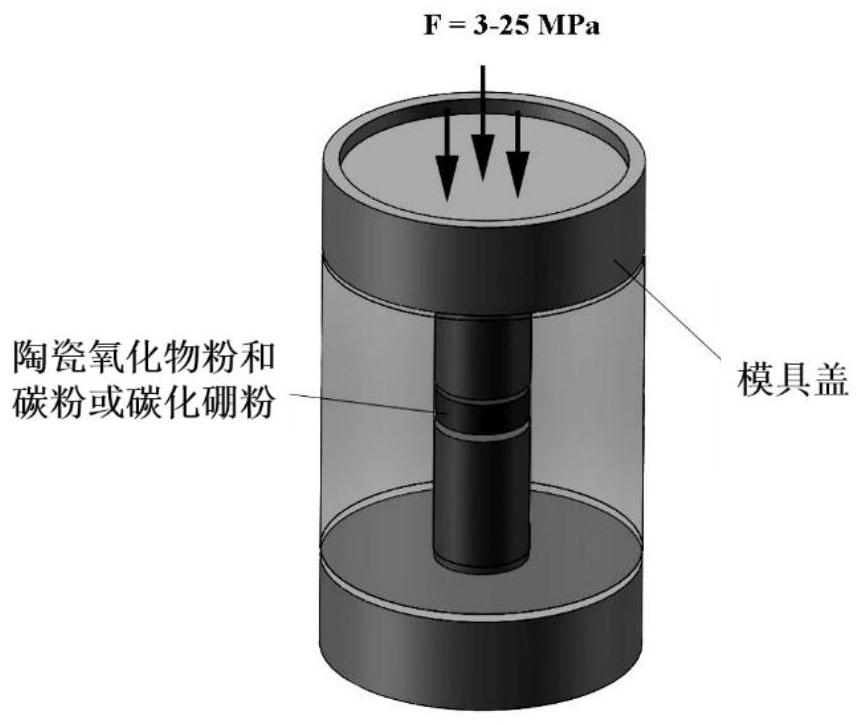

[0033] First, the particle size of the ceramic oxide powder is 50nm at the nanometer level, and the carbon powder needs to be sieved with different mesh screens to finally control the particle size of the carbon powder at 48 μm; secondly, the molar ratio of the oxide powder to the carbon (boron) powder is weighed as 0.5︰1.6, pour the weighed two powders and alcohol into a beaker and mix them, and mix them with a magnetic stirrer for 20 minutes until they are fully uniform, and then heat them on a resistance wire heating furnace until the alcohol evaporates completely, then grind them in an agate mortar And use different mesh sieves to finally control the particle size of the mixed powder at 75 μm; then, use graphite paper to spread the inner wall of the hot-pressing mold, and then spread the mixed material evenly in the mold; The hot-pressing mold is placed in a hot-pressing sintering furnace, and a compressive stress of 10,000N is applied in the vertical direction of the mold....

Embodiment 2

[0035] First of all, the particle size of ceramic oxide powder and carbon (boron) powder is 100nm at the nanometer level and 50μm at the micron level. . Secondly, weigh the molar ratio of oxide powder and carbon (boron) powder to be 1.2:3.7, pour the two powders weighed and alcohol into a beaker and mix them, and mix them with a magnetic stirrer for 60 minutes until they are fully uniform. Heat it on a resistance wire heating furnace until the alcohol evaporates completely, grind it in an agate mortar and sieve it with different mesh screens, and finally control the particle size of the mixed powder at 50 μm; then, spread the inner wall of the hot-pressing mold with graphite paper, and then Spread the mixture evenly in the mold; after that, place the hot-press mold with the powder in a hot-press sintering furnace, apply a compressive stress of 2 000 N in the vertical direction of the mold, sinter at 2100°C, and hold for 4 hours. The heating rate is 20°C / min, the argon gas is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com