Anti-aging polyamide composition and preparing method thereof

A polyamide composition and anti-aging technology, applied in the field of anti-aging polyamide composition and preparation thereof, and anti-aging polyamide composition, can solve the problem of reducing the anti-oxidation effect of polyamide, uniform anti-oxidation effect, low flexibility, etc. problems, to achieve the effect of extending service life, improving stability, and high replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

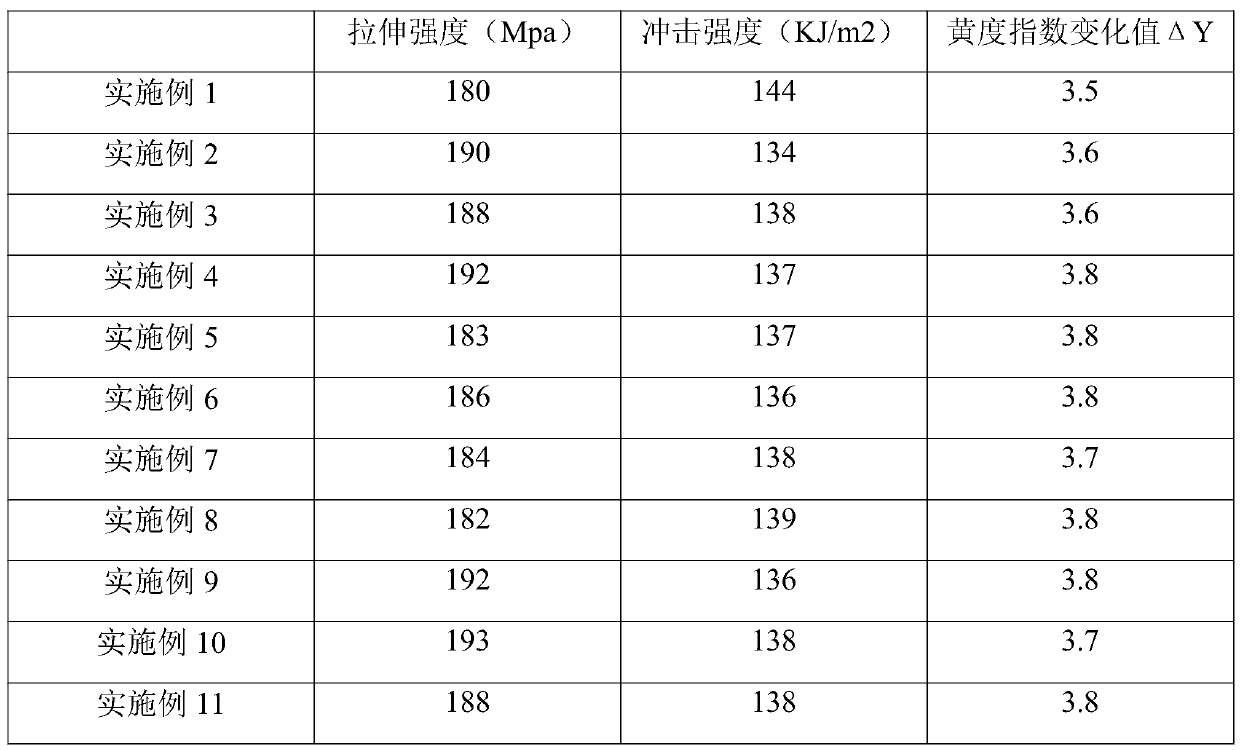

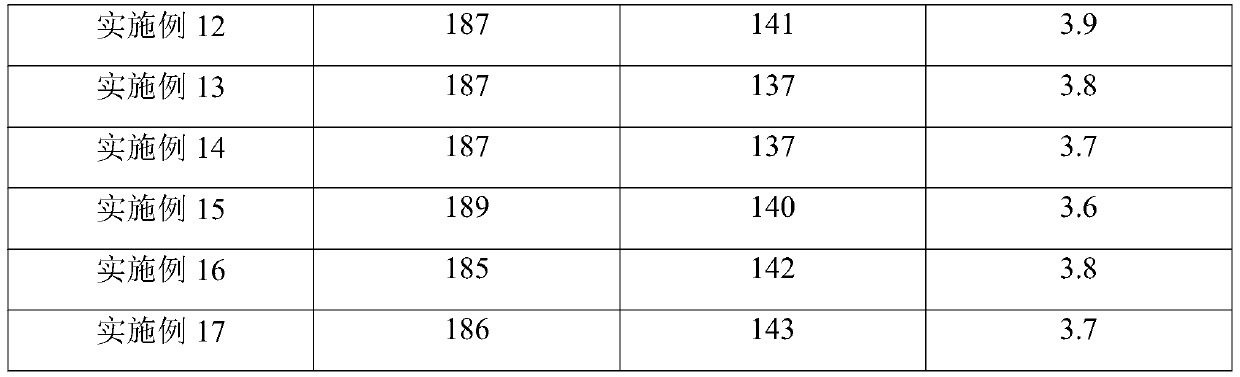

Examples

preparation example Construction

[0035] Preparation method of polyamide composition:

[0036] S1: take antioxidant, ultraviolet absorber, photostabilizer and dissolve in silicone oil, be configured into silicone oil solution;

[0037] S2: Dry the polyamide particles at 60-80°C for 1-3 hours, pulverize them, pass through a 100-mesh sieve,

[0038] S3: Low-speed stirring: Weigh a certain amount of polyamide and place it in a mixer, control the stirring temperature to 100-110°C, stir at a low speed, the stirring speed is 100-300r / min, stir for 30min, add 50% silicone oil solution at the same time, the dropping speed Control at 5ml / min;

[0039] S4: High-speed stirring: the stirring speed of high-speed stirring is controlled at 500-800r / min, stirring for 60min, and the dropping rate is controlled at 1ml / min;

[0040] S5: Stirring at high temperature: After the high-speed stirring is completed, continue to stir at high temperature, control the stirring speed at 200-600r / min, control the temperature at 190-215°C,...

Embodiment 1

[0043] The mass percentage of polyamide is 99.55%; the antioxidant is pentaerythritol tetrakis (3-lauryl thiopropionate), and the mass percentage is 0.15%; the ultraviolet absorber is 3,5-di-tert-butyl- Hexadecyl 4-hydroxybenzoate, the mass percentage is 0.15%; the light stabilizer is 1,5,8,12-tetrakis[4,6-bis(N-butyl-N-1,2,2, 6,6-pentamethyl-4-piperidinylamino)-1,3,5-triazin-2-yl]-1,5,8,12-tetraazadodecane, mass percent 0.15 %. A polycarbonate composition is constructed from this component and made into a square plate.

Embodiment 2

[0045] The mass percentage of polyamide is 95.8%; the antioxidant is triethylene glycol bis-β-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate, and the mass percentage is 1.05% The ultraviolet absorber is (2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethyl)phenol, and the mass percentage composition is 3%; the light stabilizer is Poly(4-hydroxyethyl-2,2,6,6-tetramethyl-1-piperidineethanol) ester, the mass percentage is 0.15%. A polycarbonate composition is constructed from this component and made into a square plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com