A segmented intelligent shock isolator with anti-shock characteristics

A segmented, shock isolator technology, applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems such as poor energy dissipation capacity and inability to resist impact loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

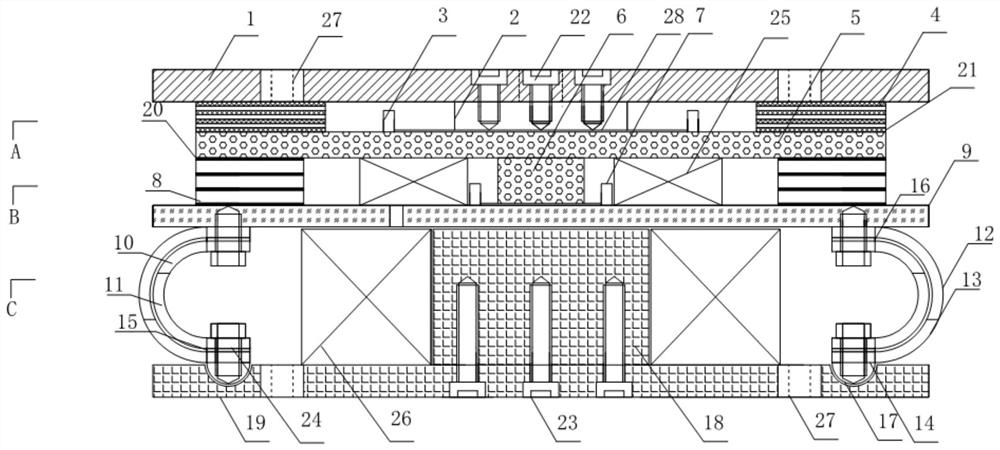

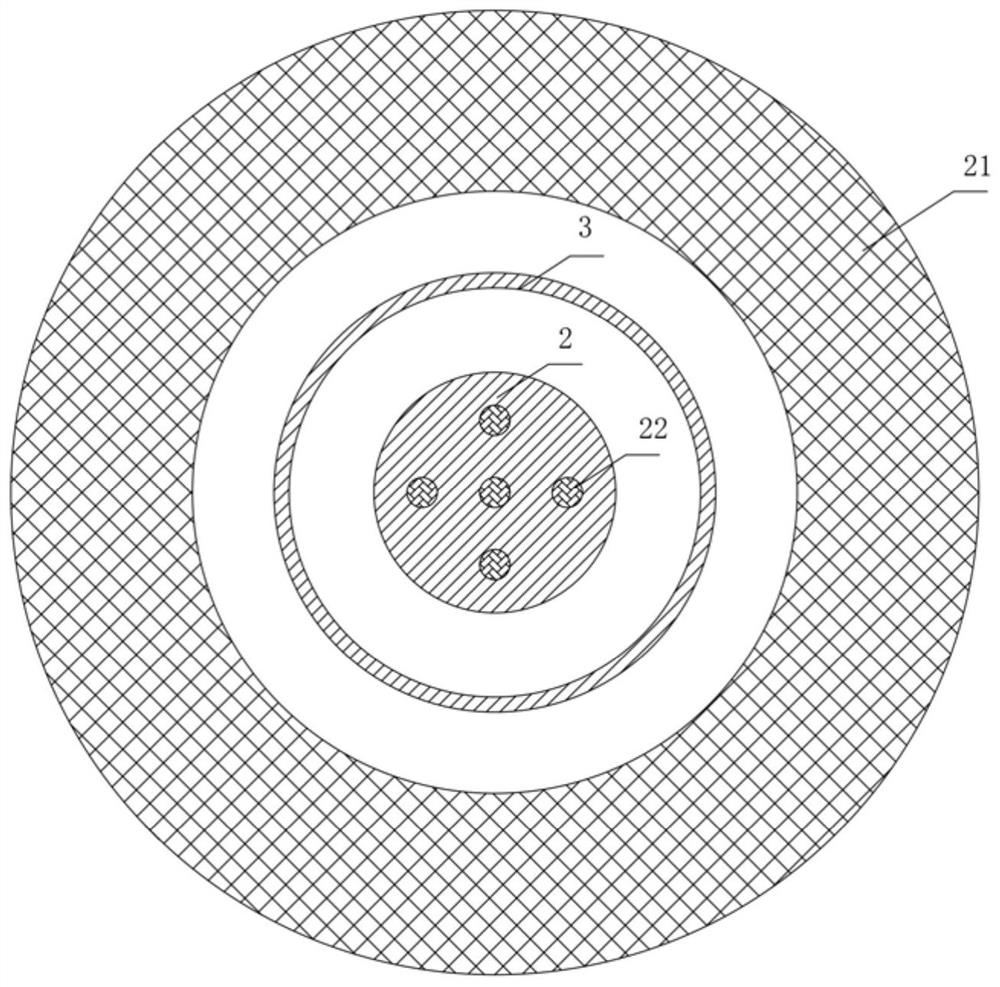

[0043] combined with figure 1 and 2 , the upper cover plate 1 and the support column A2 are connected by bolts A22, the limit ring column A3 is welded and connected with the cylindrical partition 5, the rubber 21 and the annular steel plate 4 are vulcanized into a whole, and then respectively connected with the upper cover plate 1 and the cylindrical partition The plate 5 is bonded, the upper cover plate 1, the support column A2, the limit ring column A3, the annular steel plate 4, the rubber 21, and the cylindrical partition plate 5 form the rubber vibration isolation layer of the vibration isolator; the rubber vibration isolation layer has small damping and low dynamic properties of stiffness.

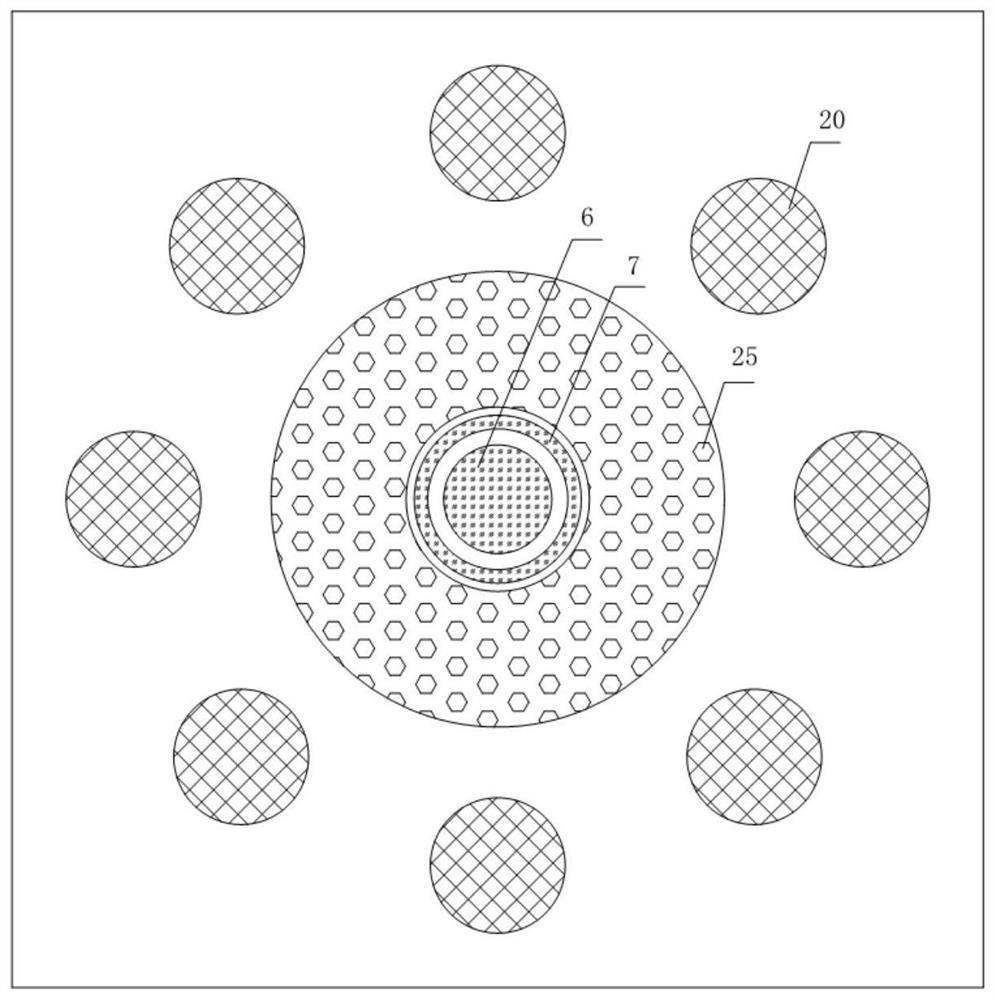

[0044] combined with figure 1 and 3 , the cylindrical partition 5 is connected to the support column B6 by welding, the limit ring column B7 is connected to the middle cover plate 8 by welding, the MRE20 and the circular steel plate 8 are vulcanized into a whole, and then combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com