Nitrogen-doped carbon material nano-enzyme based on nucleic acid bases or nucleic acid derivatives and preparation method and application of nano-enzyme

A nucleic acid base, nitrogen-doped carbon technology, applied in the direction of chemical analysis using catalysis, can solve the problems of difficult to achieve large-scale industrial production, complex process, high cost, etc., and achieve high-efficiency peroxidase-like catalytic activity , high nitrogen doping rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

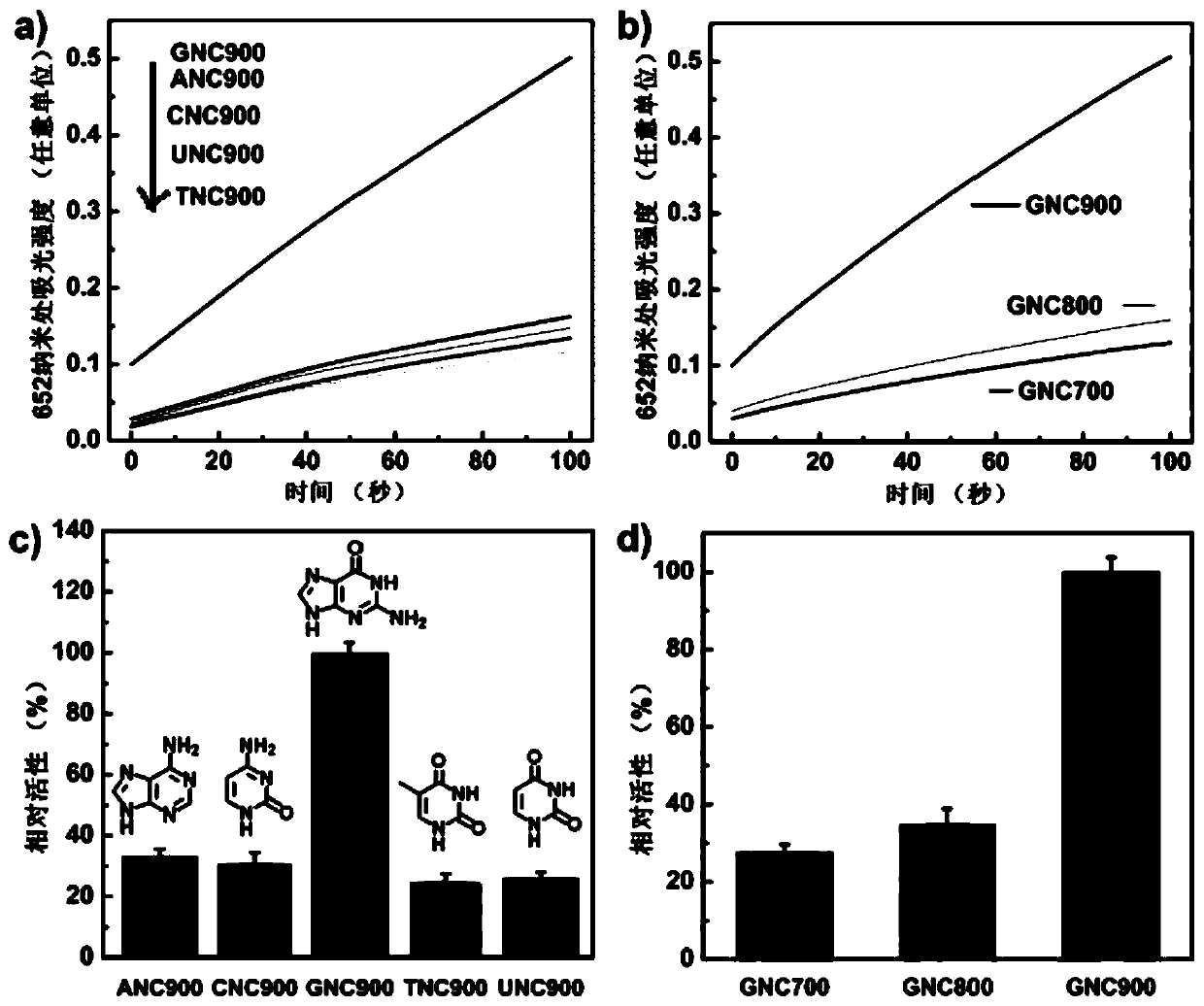

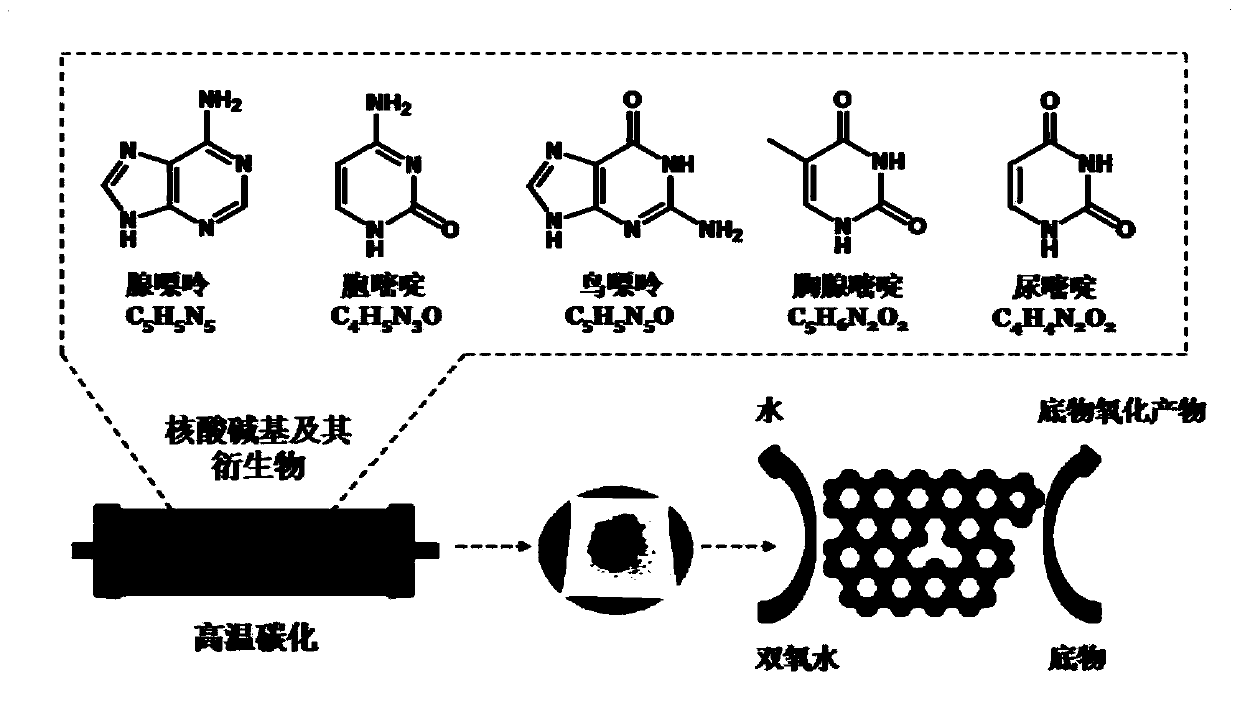

[0027] Embodiment 1 Preparation of nitrogen-doped carbon material nanozyme based on adenine

[0028] 1. Put 5 groups of adenine powder precursors into 5 groups of alumina crucibles;

[0029] 2. Place 5 alumina crucibles with adenine powder in high-temperature tube furnaces filled with argon gas;

[0030] 3. Raise the temperature of 5 sets of high-temperature tube furnaces to 600°C, 700°C, 800°C, 900°C, and 1000°C respectively.

[0031] 4. Keep the temperature of the high-temperature tube furnace at 600°C, 700°C, 800°C, 900°C, 1000°C for carbonization, and continue the reaction for 3 hours.

[0032] 5. After carbonization, cool naturally to room temperature, take out the product, and the obtained product is adenine-based nitrogen-doped carbon material nanozyme, named ANC600, ANC700, ANC800, ANC900, ANC1000 respectively.

Embodiment 2

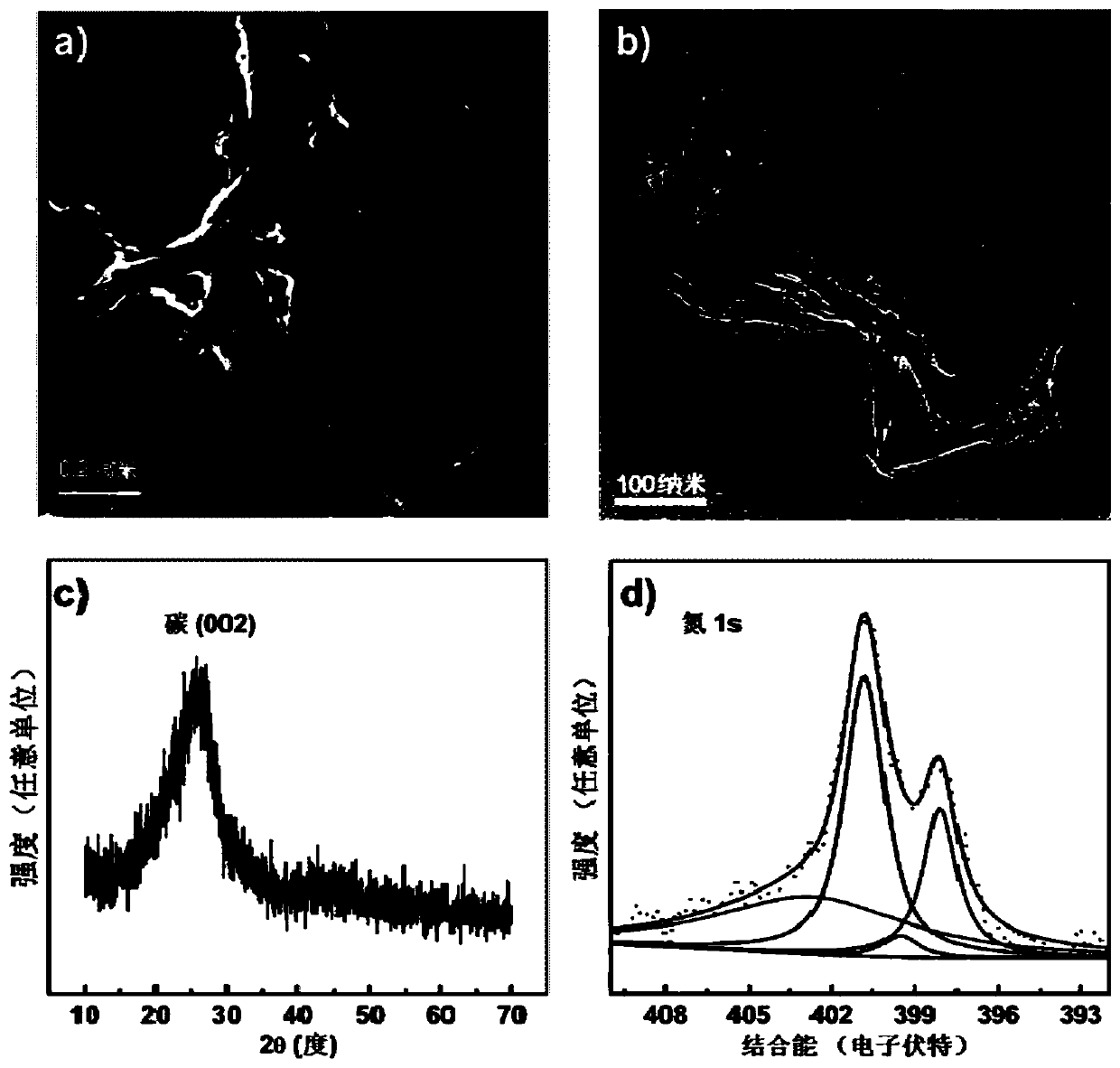

[0033] Embodiment 2 Preparation of nitrogen-doped carbon material nanozyme based on guanine

[0034] 1. Put 5 groups of guanine powder precursors into 5 groups of alumina crucibles;

[0035] 2. Place 5 alumina crucibles with guanine powder in a high-temperature tube furnace filled with argon gas;

[0036] 3. Raise the temperature of 5 sets of high-temperature tube furnaces to 600°C, 700°C, 800°C, 900°C, and 1000°C respectively.

[0037] 4. Keep the temperature of the high-temperature tube furnace at 600°C, 700°C, 800°C, 900°C, 1000°C for carbonization, and continue the reaction for 3 hours.

[0038]5. After carbonization, cool down to room temperature naturally, and take out the product. The obtained product is a carbon material nanozyme based on guanine nitrogen doping, named GNC 600, GNC700, GNC800, GNC900, and GNC1000 respectively.

Embodiment 3

[0039] Example 3 Preparation of nitrogen-doped carbon material nanozyme based on cytosine

[0040] 1. Put cytosine powder precursors in 5 groups of alumina crucibles respectively;

[0041] 2. Put 5 alumina crucibles with cytosine powder in a high-temperature tube furnace filled with argon gas;

[0042] 3. Raise the temperature of 5 sets of high-temperature tube furnaces to 600°C, 700°C, 800°C, 900°C, and 1000°C respectively.

[0043] 4. Keep the temperature of the high-temperature tube furnace at 600°C, 700°C, 800°C, 900°C, 1000°C for carbonization, and continue the reaction for 3 hours.

[0044] 5. After carbonization, cool naturally to room temperature, take out the product, and the obtained product is cytosine-based nitrogen-doped carbon material nanozyme, named CNC600, CNC700, CNC800, CNC900, CNC1000 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com