A kind of nanoporphyrin catalyst and the method utilizing its catalysis TMB color development

A catalyst and porphyrin technology, applied in the field of analysis and detection, can solve the problems of high cost of raw materials, severe synthesis process conditions, etc., and achieve the effects of overcoming instability, simple synthesis process and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of nanoporphyrin catalyst, its preparation method comprises the steps:

[0034] Dilute 9.5mL to a concentration of 2.63×10 -3 M with 500 μL of DTAB aqueous solution at a concentration of 1 x 10 -5 M ZnTPyP mixed with N,N-dimethylformamide solution, ultrasonic (100W, 25°C) for 10-15min, then heated to 70°C in a water bath for 15-20min to initiate a self-assembly reaction to obtain a nanoporphyrin catalyst (DTAB-ZnTPyP ).

[0035] The nano-porphyrin catalyst obtained in this embodiment is used to catalyze TMB color development, and the specific steps include:

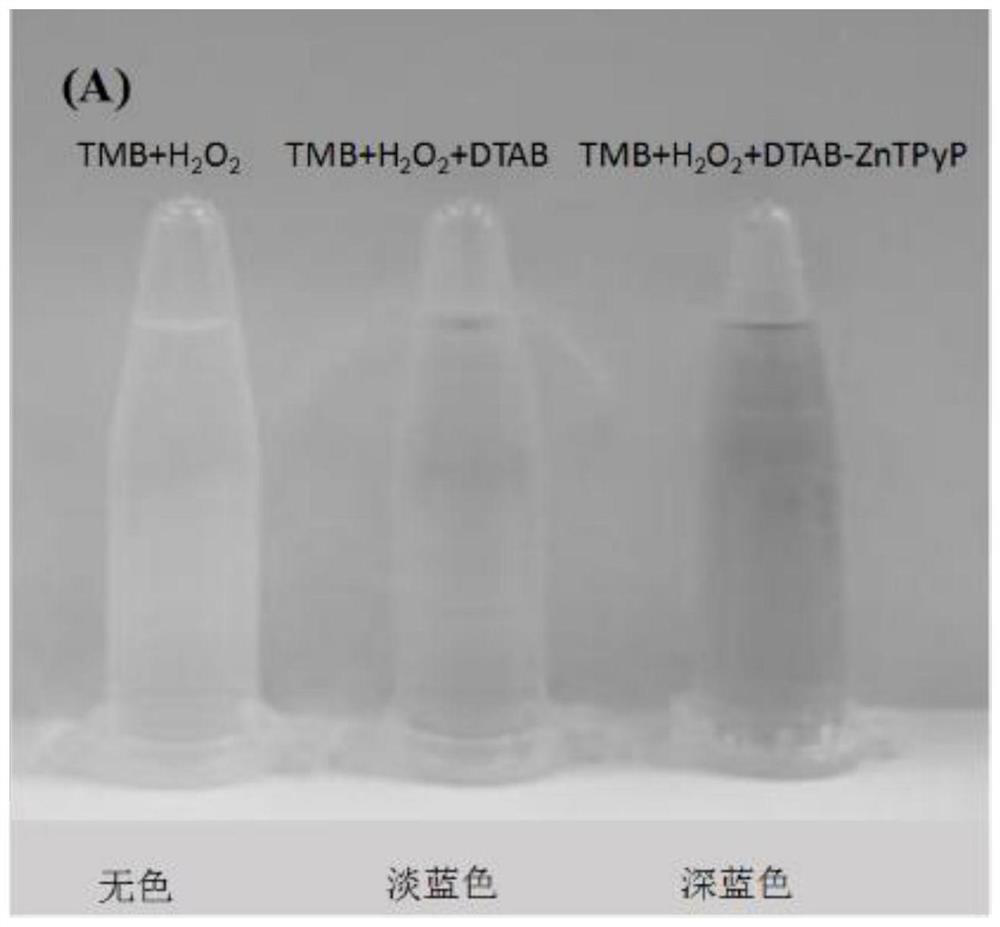

[0036] Dilute 100 μL to a concentration of 5 x 10 -7 M nanoporphyrin, added to 100 μL of N,N-dimethylformamide solution with a concentration of 3 mM TMB, 100 μL with a concentration of 30% H 2 o 2 solution, 700μL acetate buffer solution (0.2M, pH=3.6) to form the mixed chromogenic system I (TMB+H 2 o 2 +DTAB-ZnTPyP), incubated at 40°C for 8min, the color response of the solution system is as follows ...

Embodiment 2

[0041] A kind of nanoporphyrin catalyst, its preparation method comprises the steps:

[0042] Dilute 9.5mL to a concentration of 2.63×10 -2 M DTAB aqueous solution with 500 μl concentration of 1 x 10 -5M ZnTPyP mixed with N,N-dimethylformamide solution, ultrasonic (100W, 25°C) for 10-15min, then heated to 70°C in a water bath for 15-20min to initiate a self-assembly reaction to obtain a nanoporphyrin catalyst (DTAB-ZnTPyP ).

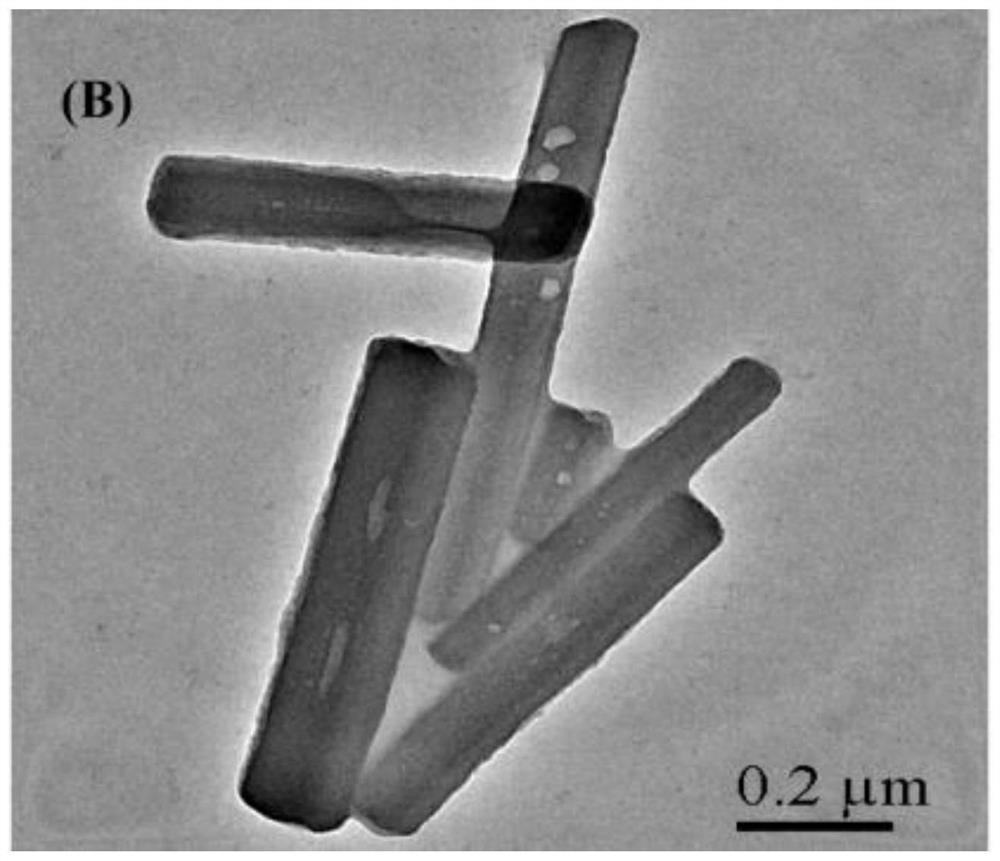

[0043] figure 2 This is the electron micrograph of the nano-porphyrin catalyst obtained in this example. It can be seen from the figure that the obtained product has a nano-rod structure with a particle size of 70-80 nm.

Embodiment 3

[0045] A kind of method utilizing nano porphyrin catalyst to catalyze TMB color development, comprises the steps:

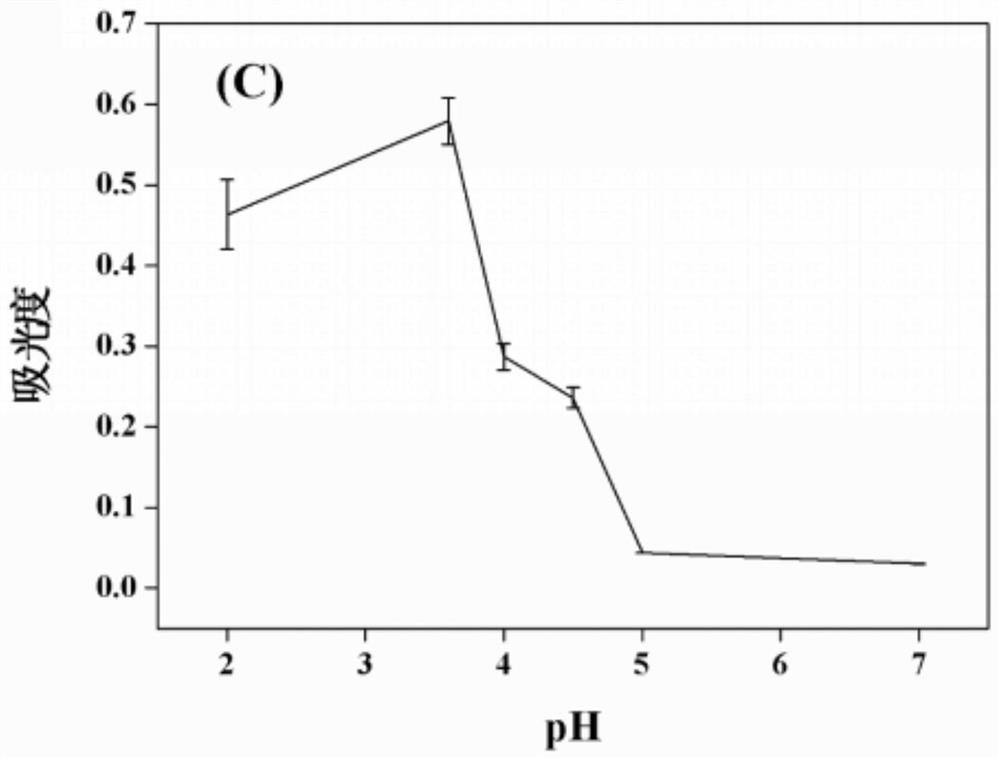

[0046] To a concentration of 5 x 10 containing 100 μL -7 M's nano-porphyrin aqueous solution (prepared in Example 2), 100 μL 3×10 -3 N,N-dimethylformamide solution of MTMB and 100 μL of 30% H 2 o 2 Add 700 μL of 0.2M acetate buffer solution with different pH values (pH is 2.0, 3.6, 4.0, 4.5, 6, 7) to the six mixed solutions of the aqueous solution, incubate the reaction at 40°C for 8 minutes, and carry out ultraviolet Scanning (at 652nm) results such as image 3 shown.

[0047] The results showed that when the pH value of the acetate buffer solution was in the range of 2.0-4.5, the nano-porphyrins could show a good catalytic effect on TMB, and the best catalytic performance was shown at pH=3.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com