Preparation method of integrase

A technology of integrating enzymes and skeleton materials, applied in biochemical equipment and methods, chemical instruments and methods, medical preparations containing active ingredients, etc. To achieve the effect of no toxic effect, sensitive results and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

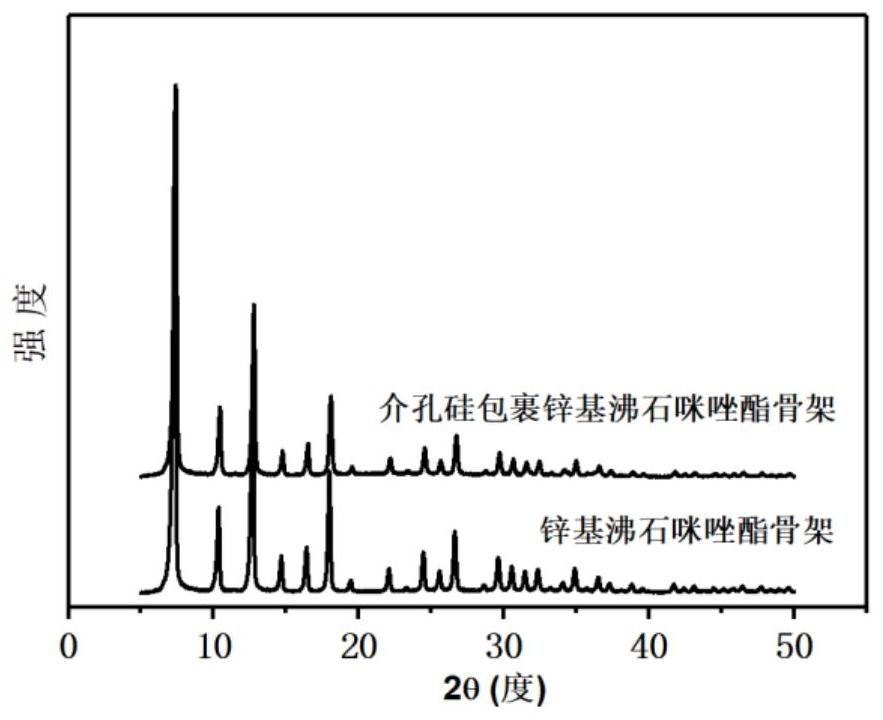

[0033] (1) Preparation of zeolite imidazolate framework material: 9.5197g of zinc nitrate hexahydrate and 3.0769g of 2-methylimidazole were dissolved in 500mL and 400mL of methanol, respectively, after the dissolution was complete, mixed, and stirred at room temperature at 1000 rpm for 2 hours . Centrifuge at 13,000 rpm, wash with methanol three times, and vacuum dry at 60°C overnight.

[0034] (2) Preparation of mesoporous silicon-wrapped zeolite imidazolate framework material: 2.6 g of zeolite imidazolate framework material was dispersed in 24 mL of methanol. 216 mL of distilled water was added (total volume 240 mL, 10 vol% methanol). The pH was adjusted to 11 by adding 1M sodium hydroxide. 0.2016 g of cetyltrimethylammonium bromide was added and stirred for 30 minutes. 1.2 mL of tetraethyl orthosilicate was added under stirring at 1000 rpm and stirred for 30 minutes. Centrifuge at 13,000 rpm and wash three times with methanol. Dry under vacuum at 60°C overnight.

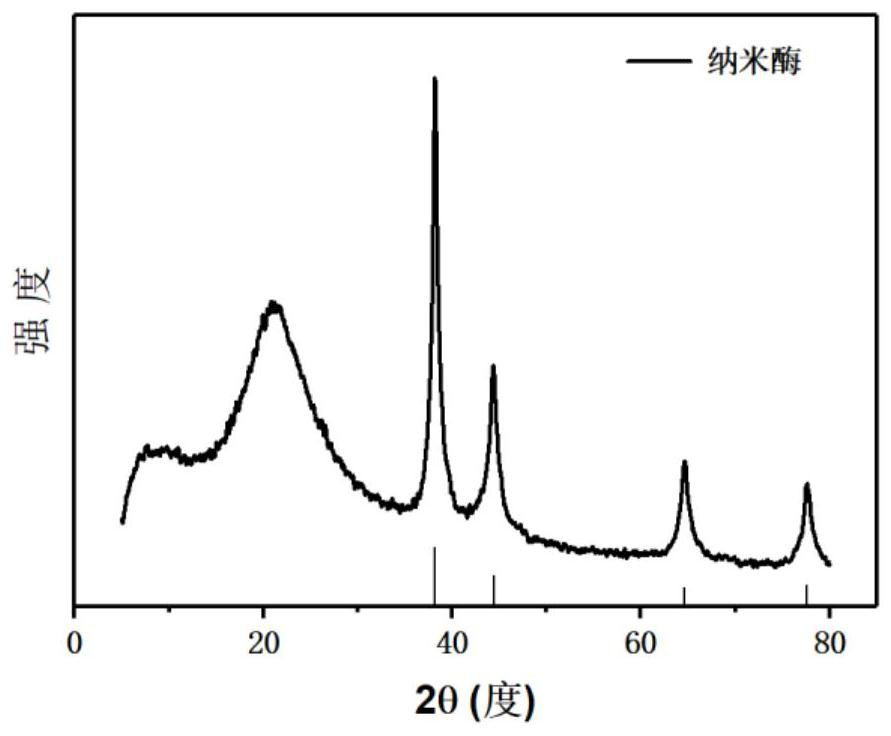

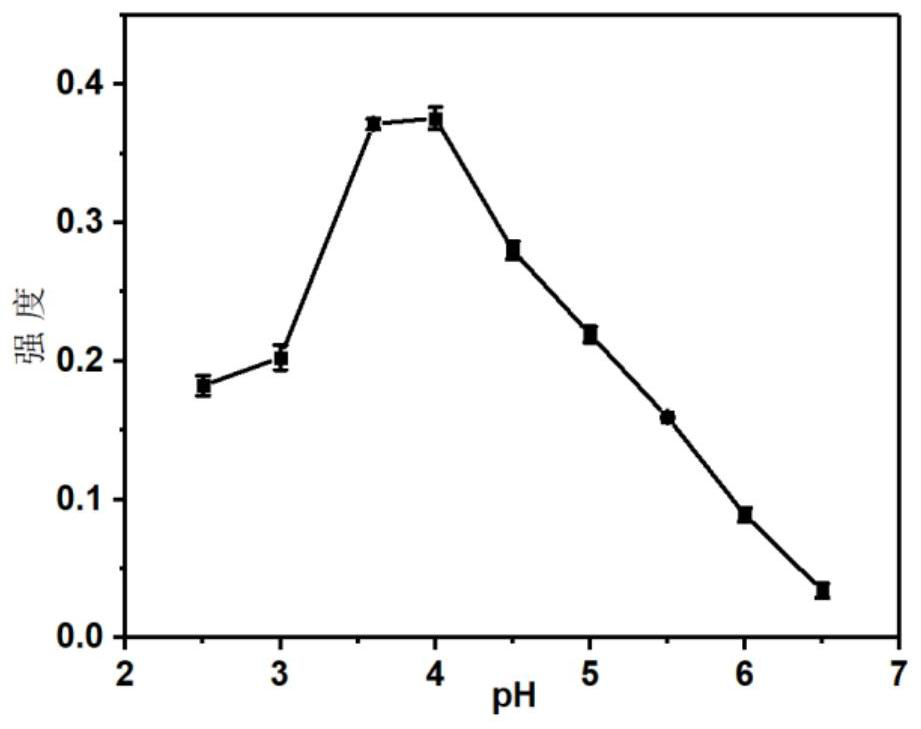

[0035...

Embodiment 2

[0040] (1) Preparation of zeolite imidazolate framework material: 9.5197g of zinc nitrate hexahydrate and 3.0769g of 2-methylimidazole were dissolved in 500mL and 400mL of methanol, respectively, after the dissolution was complete, mixed, and stirred at room temperature at 1000 rpm for 2 hours . Centrifuge at 13,000 rpm, wash with methanol three times, and vacuum dry at 60°C overnight.

[0041] (2) Preparation of mesoporous silicon-wrapped zeolite imidazolate framework material: 2.6 g of zeolite imidazolate framework material was dispersed in 24 mL of methanol. 216 mL of distilled water was added (total volume 240 mL, 10 vol% methanol). The pH was adjusted to 11 by adding 1M sodium hydroxide. 0.2016 g of cetyltrimethylammonium bromide was added and stirred for 30 minutes. 1.2 mL of tetraethyl orthosilicate was added at 1000 rpm and stirred for 30 minutes. Centrifuge at 13,000 rpm and wash three times with methanol. Dry under vacuum at 60°C overnight.

[0042] (3) Prepara...

Embodiment 3

[0046] (1) Preparation of zeolite imidazolate framework material: 9.5197g of zinc nitrate hexahydrate and 3.0769g of 2-methylimidazole were dissolved in 500mL and 400mL of methanol, respectively, after the dissolution was complete, mixed, and stirred at room temperature at 1000 rpm for 2 hours . Centrifuge at 13,000 rpm, wash with methanol three times, and vacuum dry at 60°C overnight.

[0047] (2) Preparation of mesoporous silicon-wrapped zeolite imidazolate framework material: 2.6 g of zeolite imidazolate framework material was dispersed in 24 mL of methanol. 216 mL of distilled water was added (total volume 240 mL, 10 vol% methanol). The pH was adjusted to 11 by adding 1M sodium hydroxide. 0.2016 g of cetyltrimethylammonium bromide was added and stirred for 30 minutes. 1.2 mL of tetraethyl orthosilicate was added at 1000 rpm and stirred for 30 minutes. Centrifuge at 13,000 rpm and wash three times with methanol. Dry under vacuum at 60°C overnight.

[0048] (3) Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com