Temperature control system and temperature control method for multiple QCMs (quartz crystal microbalances)

A temperature control system and constant temperature technology, which is applied in the direction of using electric mode for temperature control, etc., can solve the problems of complicated pipeline installation and large consumption of liquid nitrogen, and achieve simple installation process, low consumption of liquid nitrogen, and the number of pipelines. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

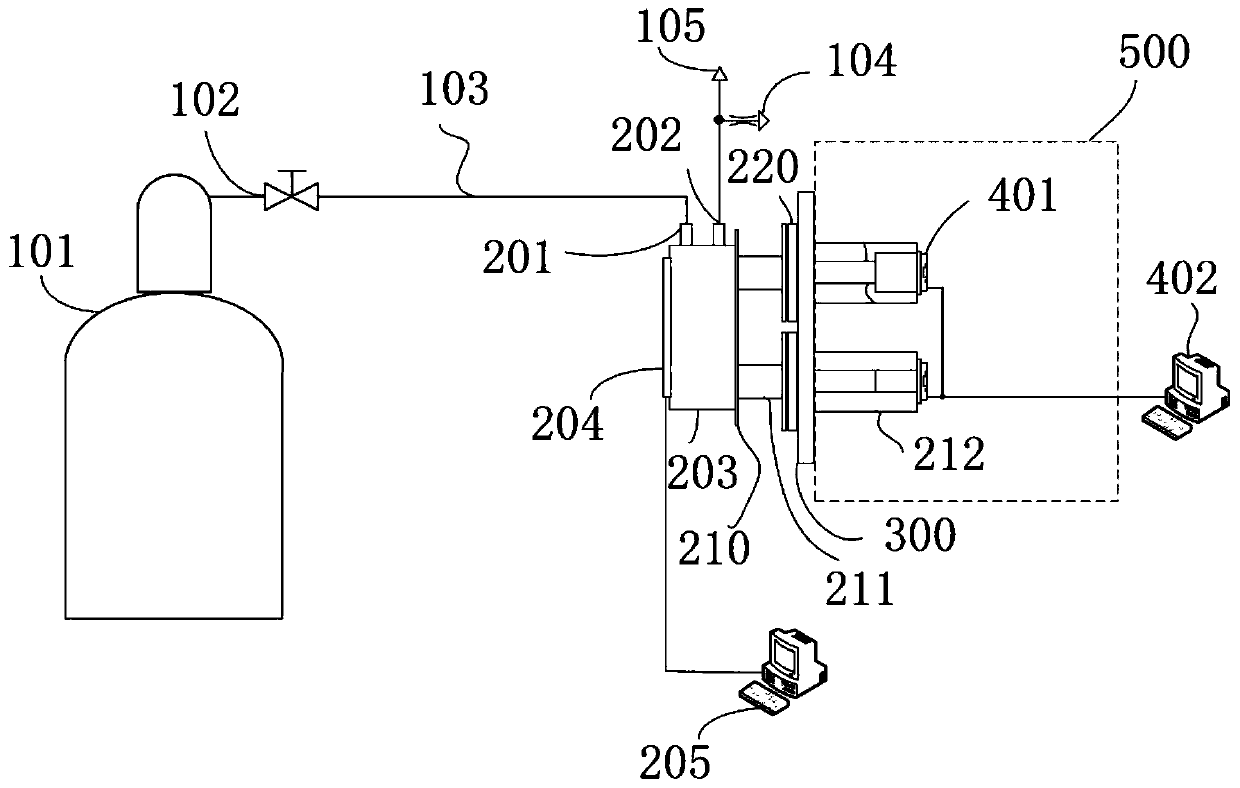

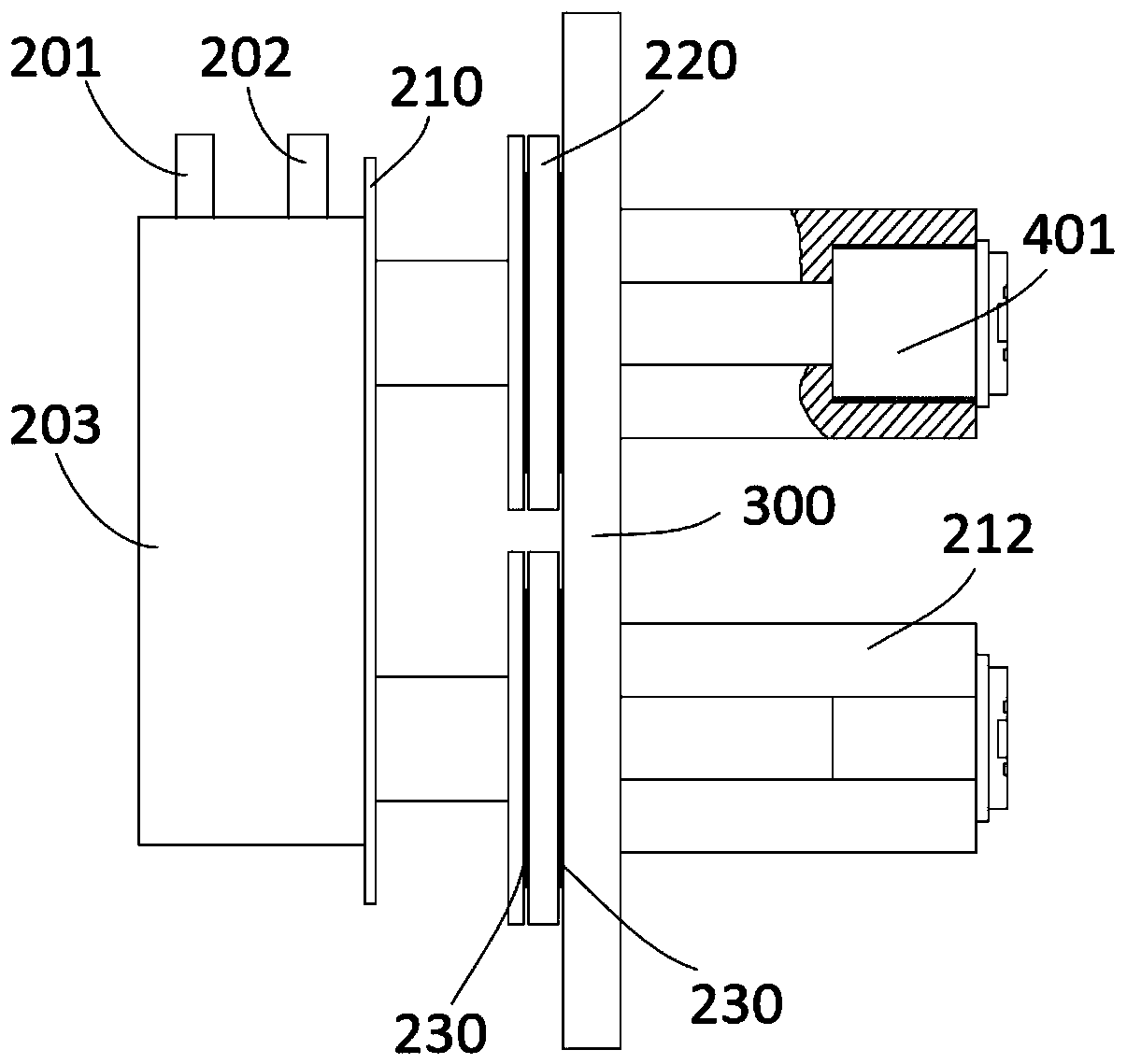

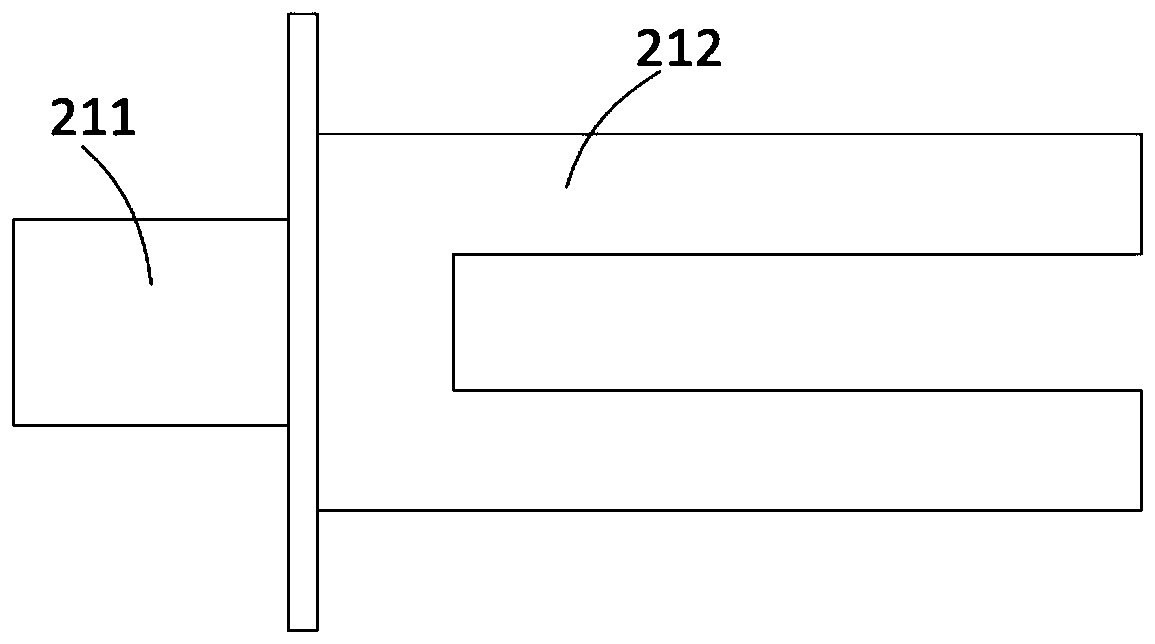

[0049] Such as figure 1 As shown, the temperature control system for multiple QCMs provided by the embodiment of the present invention includes: a constant temperature mechanism, a heat transfer assembly, and a plurality of quartz crystal microbalances (for ease of description, the quartz crystal microbalances are hereinafter referred to as QCMs) , its reference number in the accompanying drawings is 401). in:

[0050] The constant temperature mechanism includes: a thermostat 203, a refrigerator and a heater, and the refrigerator and the heater are connected with the thermostat 203 respectively. The liquid nitrogen tank 101 transports liquid nitrogen from the pressurized liquid nitrogen tank 101 to the thermostat 203, specifically, the liquid nitrogen enters the circulation pipeline inside the thermostat 203 through the liquid nitrogen inlet 201 of the thermostat 203, so that the thermostat The temperature of 203 is lowered, and finally discharged into the atmosphere through...

Embodiment 2

[0069] Embodiment 2 of the present invention proposes a temperature control method, which is applied to the temperature control system for multiple QCMs provided in Embodiment 1 above (such as figure 1 shown), temperature control methods include:

[0070] Multiple quartz crystal microbalances are installed on the heat transfer assembly of the temperature control system for multiple QCMs, and the lowest value T among the target temperatures of multiple quartz crystal microbalances is taken min ;

[0071] Regulate the temperature of thermostat 203 by refrigerator and heater, make the temperature of thermostat 203 reach T min ;

[0072] The heat transfer assembly conducts the temperature of the thermostat 203 to the quartz crystal microbalance, so that the temperature of each quartz crystal microbalance reaches T min ;

[0073] The corresponding QCM401 is heated by the heating element on the surface of the QCM401, so that the temperature of each QCM401 rises to its respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com