Crystal epitaxial structure and growth method

An epitaxial growth and epitaxial structure technology, applied in semiconductor devices, photovoltaic power generation, sustainable manufacturing/processing, etc., to achieve the effects of reducing strain, reducing thickness, and suppressing dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

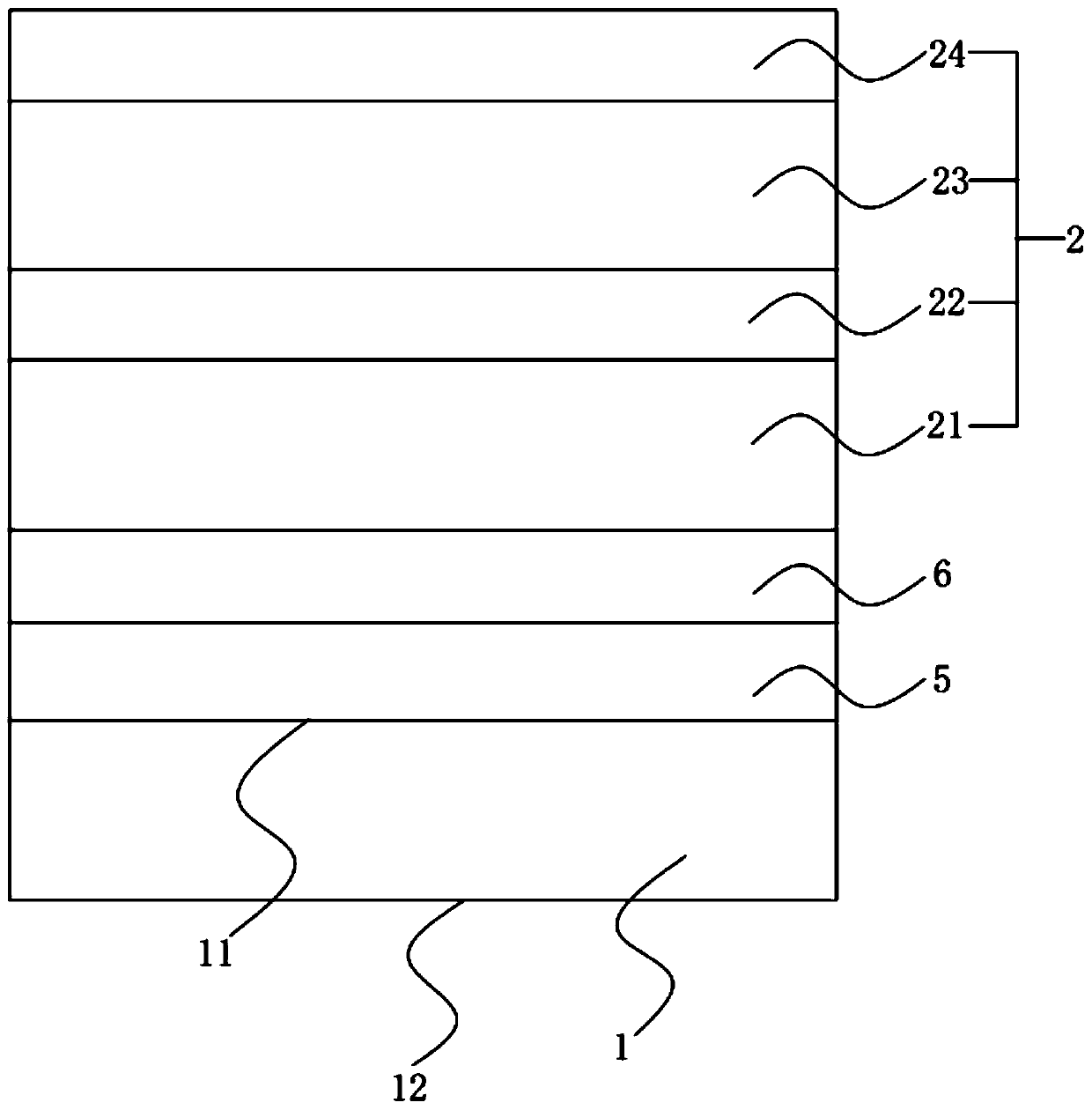

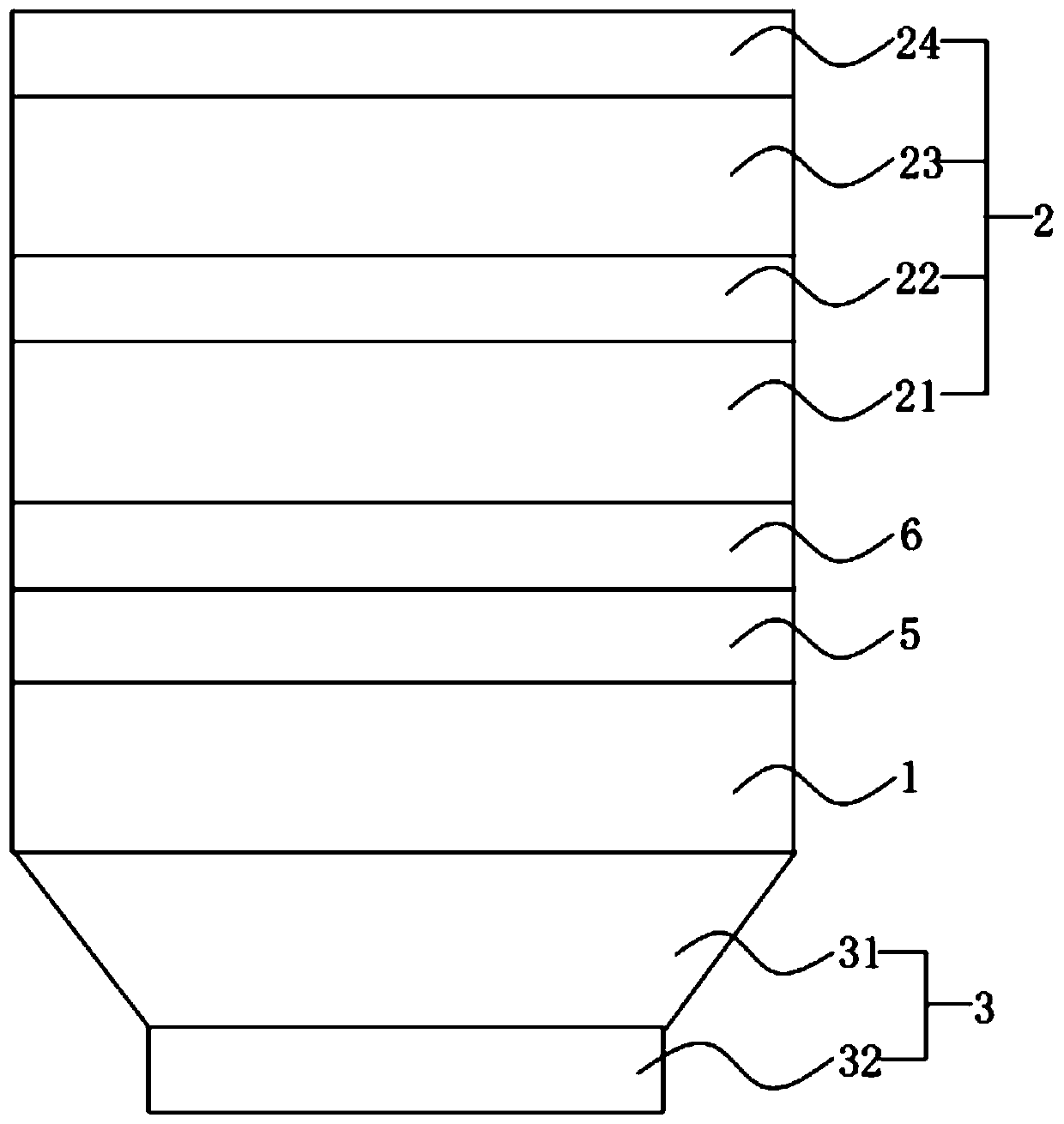

[0050] An embodiment of the present invention provides a crystal epitaxial growth method for preparing a GaInP / GaAs / InGaAs flip-chip triple-junction solar cell. like Figure 1-5 As shown, it specifically includes the following steps:

[0051] Step S1 , forming a lattice matching layer 2 on the first surface 11 of the substrate 1 . Wherein, the lattice constant of the lattice matching layer 2 is the same as that of the substrate 1 .

[0052] In this embodiment, the substrate 1 is selected from but not limited to GaAs, InP, InAs and other substrate materials.

[0053] As a preferred implementation manner, the lattice matching layer 2 includes a first sub-cell layer 21 , a first tunnel junction 22 , a second sub-cell layer 23 and a second tunnel junction 24 . Step S11 comprises the following steps:

[0054] Step S11 , forming a first sub-cell layer 21 on the first surface 11 of the substrate 1 . Wherein, the first sub-cell layer 21 is a GaInP sub-cell layer.

[0055] Step S...

Embodiment 2

[0082] An embodiment of the present invention provides a crystal epitaxial structure, specifically a GaInP / GaAs / InGaAs flip-chip triple-junction solar cell structure. like Figure 1-4 As shown, a substrate 1 , a lattice matching layer 2 , a first lattice mismatching layer 3 and a second lattice mismatching layer 4 are included. in,

[0083] The substrate 1 has an opposite first surface 11 and a second surface 12 , that is, the first surface 11 and the second surface 12 are two surfaces on the substrate 1 facing away from each other. Moreover, the first surface 11 and the second surface 12 are polished surfaces.

[0084] As a preferred embodiment, the thickness of the substrate 1 is 300 μm.

[0085] In this embodiment, the substrate 1 is selected from but not limited to GaAs, InP, InAs and other substrate materials.

[0086] The lattice matching layer 2 and the second lattice mismatching layer 4 are sequentially disposed on the first surface 11 . Wherein, the lattice const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com