Filter structure and intake structure for air purifier

An air purifier and filter technology, which is applied in the field of suction structure, can solve the problems of large ventilation resistance and insufficient performance of the main body of the filter, so as to avoid obstacles, inhibit the generation or reproduction of bacteria or viruses, and be easy to install Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0185] Hereinafter, based on an Example, this invention is demonstrated concretely. In addition, this embodiment is not limited to the structure of an Example.

[0186] I. Structure of the filter structure used for the test

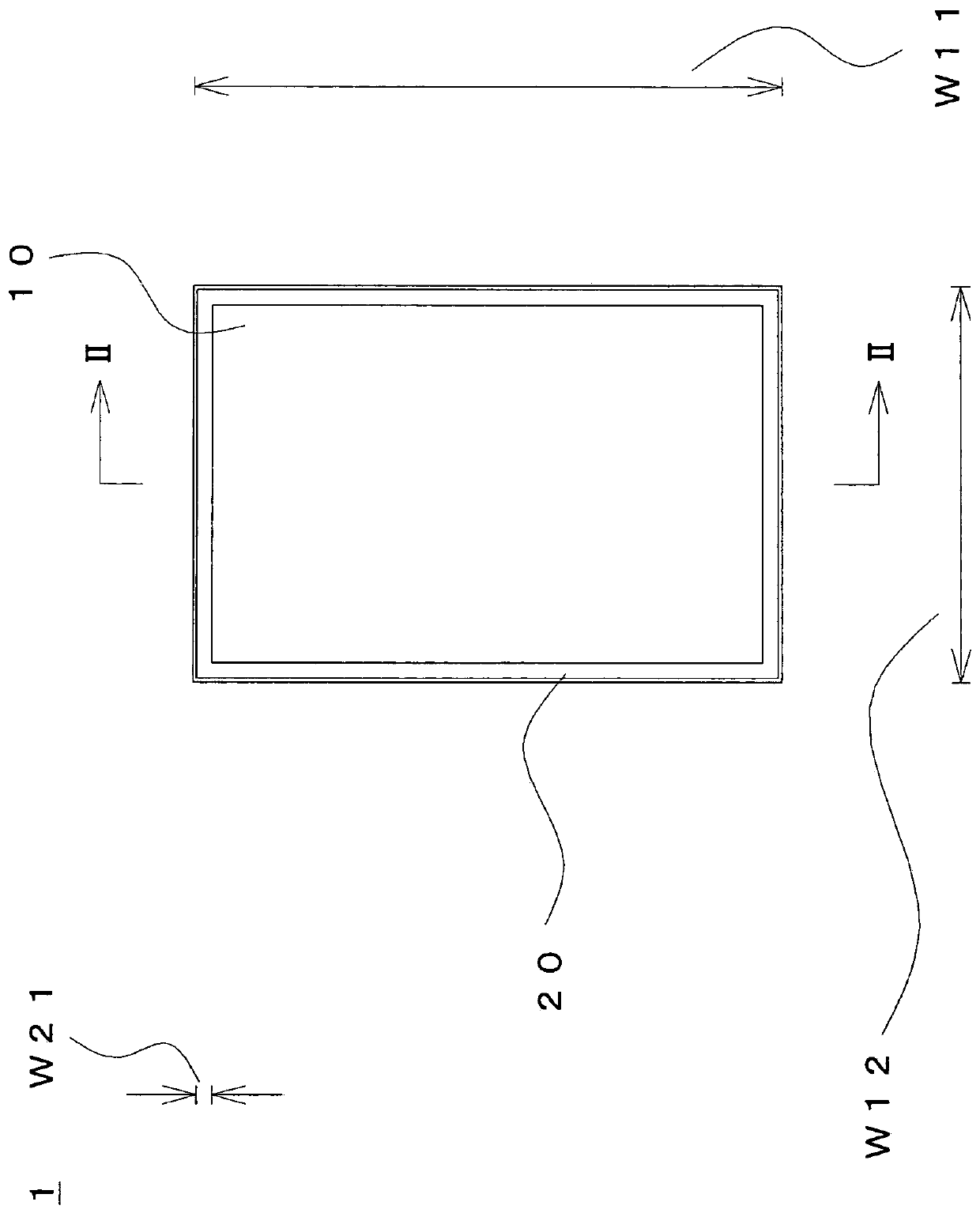

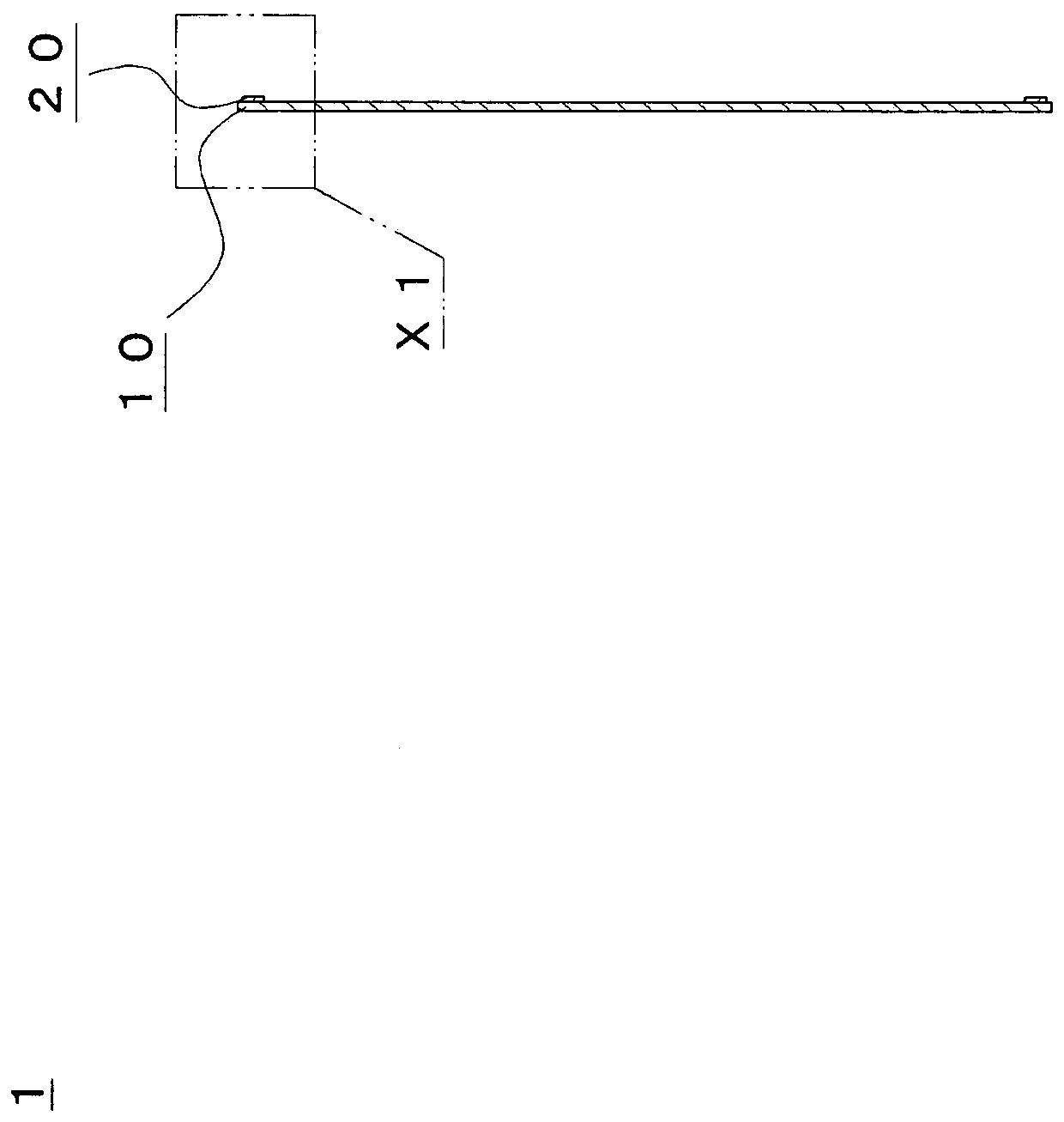

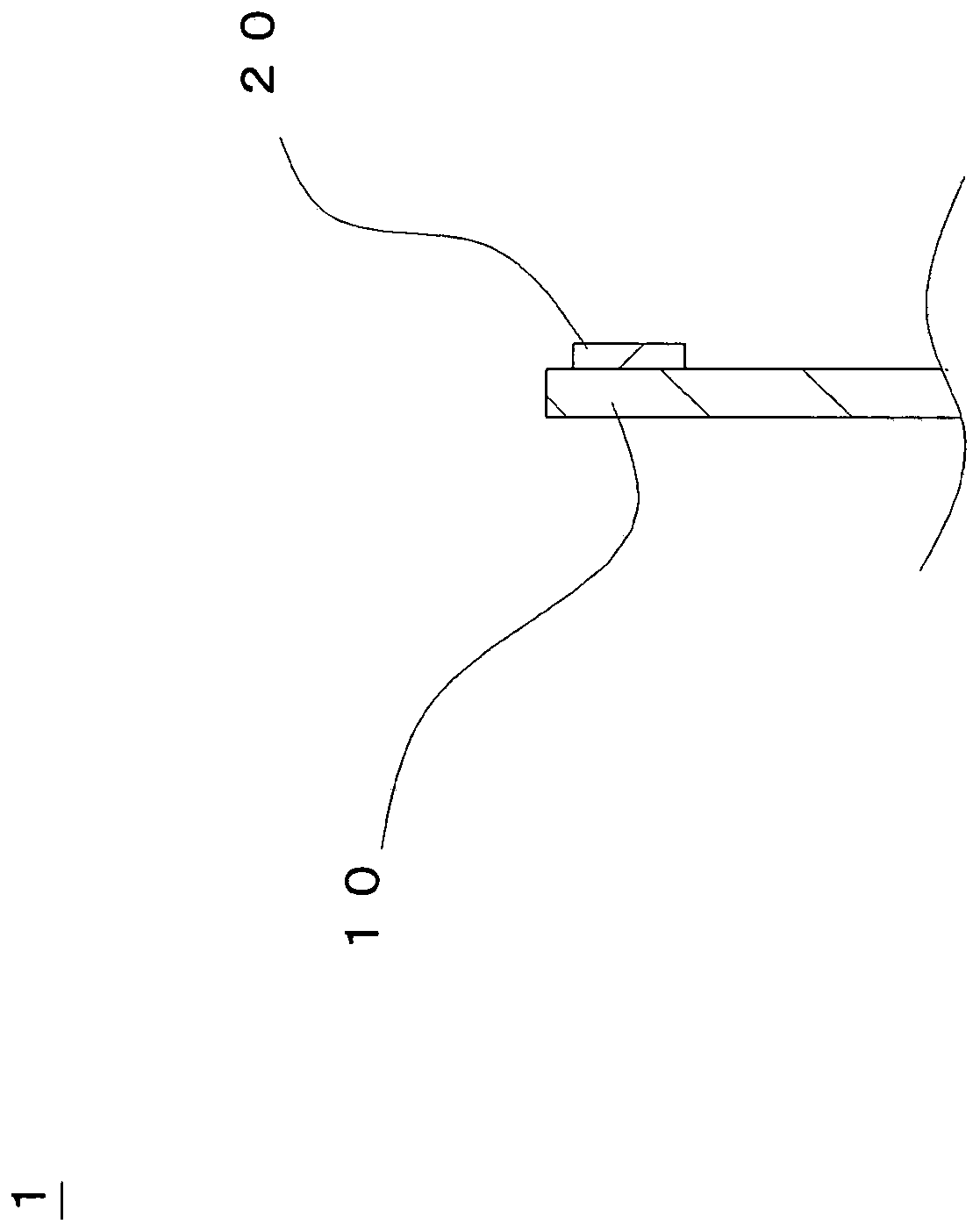

[0187] As an example, a total of seven types were prepared and formed on the filter main body made of non-woven fabric as described above. figure 1 The filter structure of the fixing part of the adhesive pattern shown by etc. (namely, the filter structure based on 1st embodiment), and it is a filter structure which differs in weight per unit area and air flow.

[0188] Examples 1 to 7 are configured so that the air flow rate of the filter body measured based on the JIS L 1096A method (Fraser method) is 1500 to 5000 cc / cm 2 / sec range.

[0189] In addition, as Comparative Example 1, a filter structure in which a fixing portion as in Examples 1 to 7 was not provided in a filter main body made of a nonwoven fabric was prepared. In addition, the weight pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com