Harmless animal carcass treatment machine

An animal carcass and processor technology, applied in grain processing and other directions, can solve the problems of poor smashing effect of large animal carcasses, poor smashing effect of animal carcasses, and long heating and disinfection treatment, and achieves good sterilization and disinfection effect and pulverization effect. Good, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

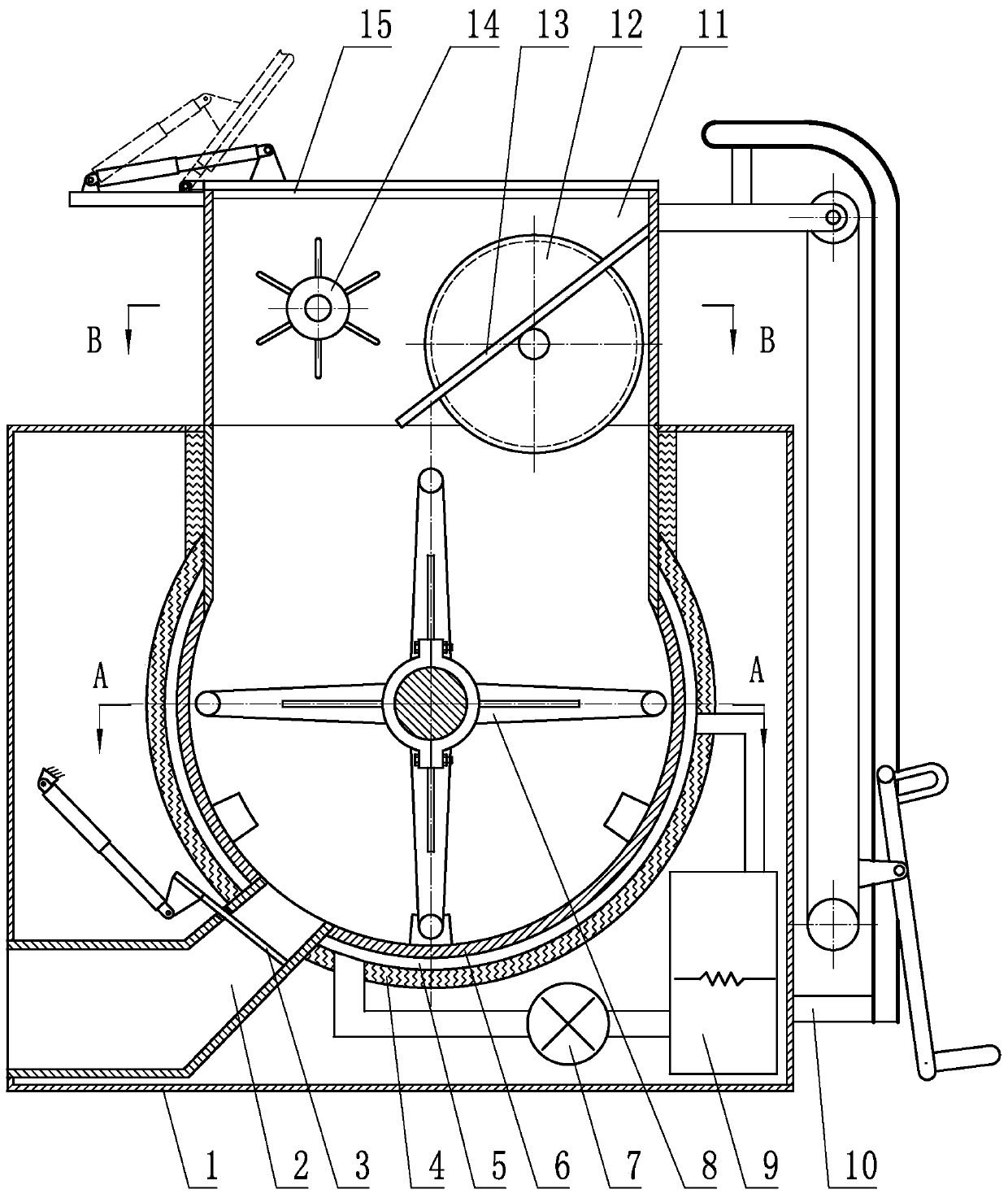

[0028] Embodiment 1: refer to Figure 1~3 , is a schematic diagram of the structure of Embodiment 1 of the present invention, including a housing 1, a heater 9, a stirring tank 6 and a stirring and pulverizing knife 8, and the stirring tank 6 is provided with a feed port 11 and a discharge port 2.

[0029] The housing 1 is provided with a feeding mechanism 9. In this embodiment, the feeding mechanism 9 is a chain hoist, which includes a lifting chain, a track and a material rack. A connection point is connected with the lifting chain. When the lifting chain moves, the material rack moves along the track with the lifting chain and lifts the material to the feeding port. The lifting chain can also be replaced by a hydraulic mechanism or an electric mechanism.

[0030] Of course, the above-mentioned feeding mechanism can also be replaced by other border customs mechanisms, such as conveyor belts or other types of elevators.

[0031] A feed port door 15 is provided at the feed p...

Embodiment 2

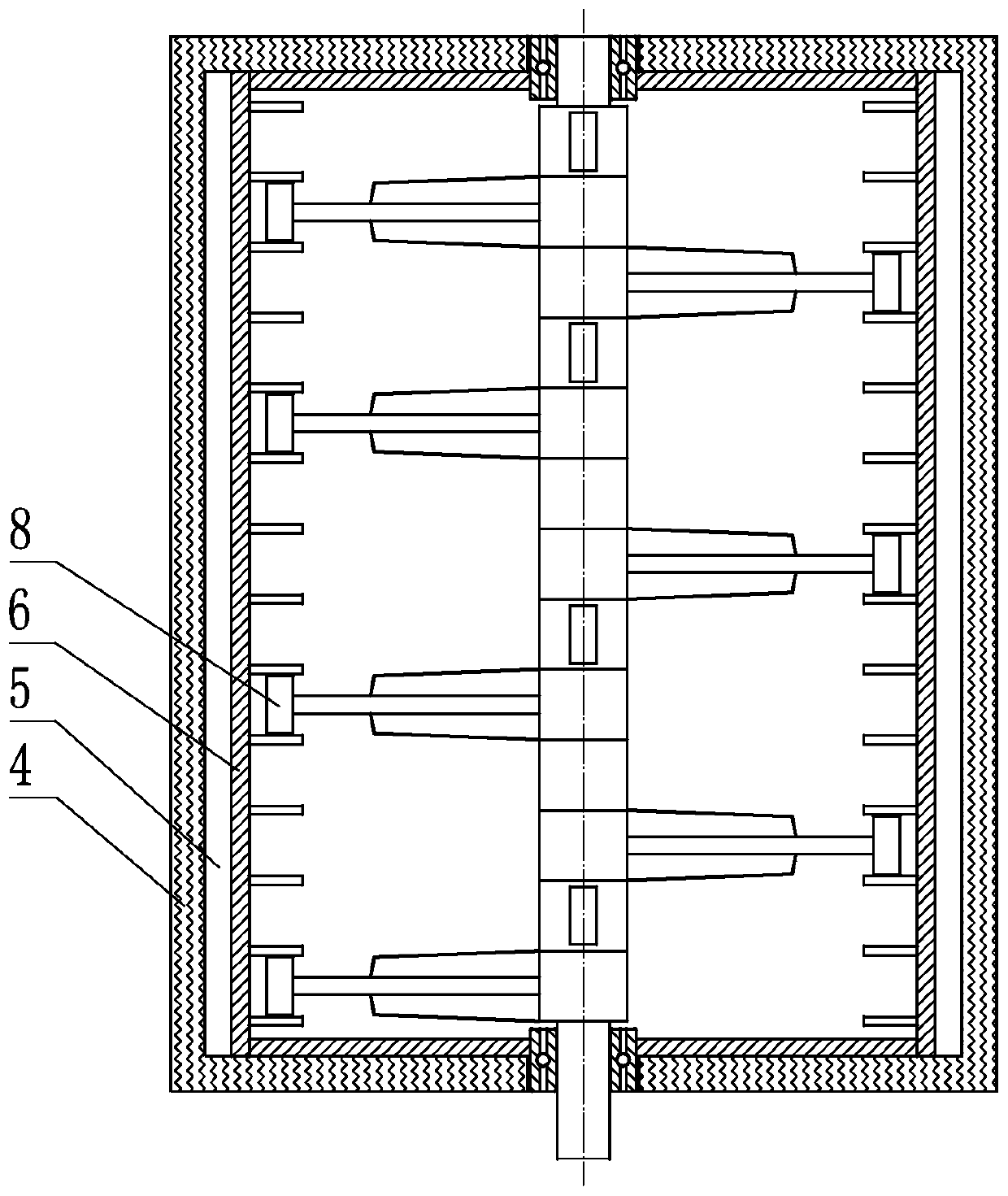

[0037] Embodiment 2: refer to Figure 4 , is a schematic structural diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the stirring tank 6 is provided with a secondary cracking mechanism, and the secondary cracking mechanism includes the side of the stirring tank 6 The transverse groove 16 on the wall is provided with the second circular saw group 17 in the groove 16, and this second circular saw group 17 is made of several disc-shaped saw blade bodies, and the second circular saw group 17 A second guide plate body 18 is arranged below, and the second guide plate body 18 is a fence-shaped body at the lower part of the second circular saw group 17 .

[0038] In this embodiment, during the stirring process, the materials in the stirring tank can be further cut and pulverized to improve the pulverization effect.

Embodiment 3

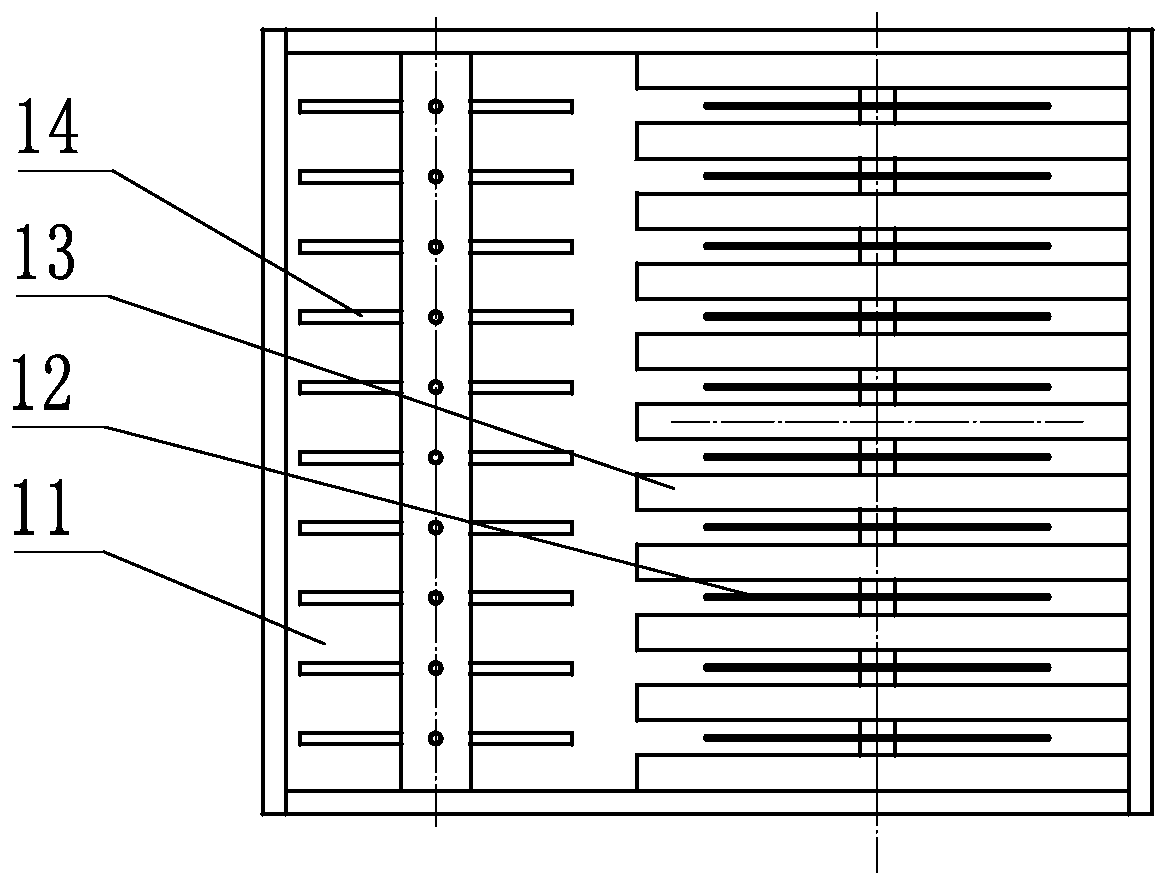

[0039] Embodiment 3: refer to Figure 5 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with the previous embodiments, the difference of this embodiment is that: the first circular saw group 12 is provided in two parallel groups at the feeding port 11 . Preferably, the circular saw blades of the two first circular saw groups 12 overlap in a cutting shape.

[0040] In this embodiment, the material can be cut and pulverized more evenly during feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com