Resistance welding method adopting piezoelectric actuator to assist pressure applying

A piezoelectric actuator and resistance welding technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient dynamic response to loading, inability to program and control pressure, etc., to improve welding production efficiency and quality , Improve the quality of solder joints, easy to update the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be specifically described below with reference to the drawings.

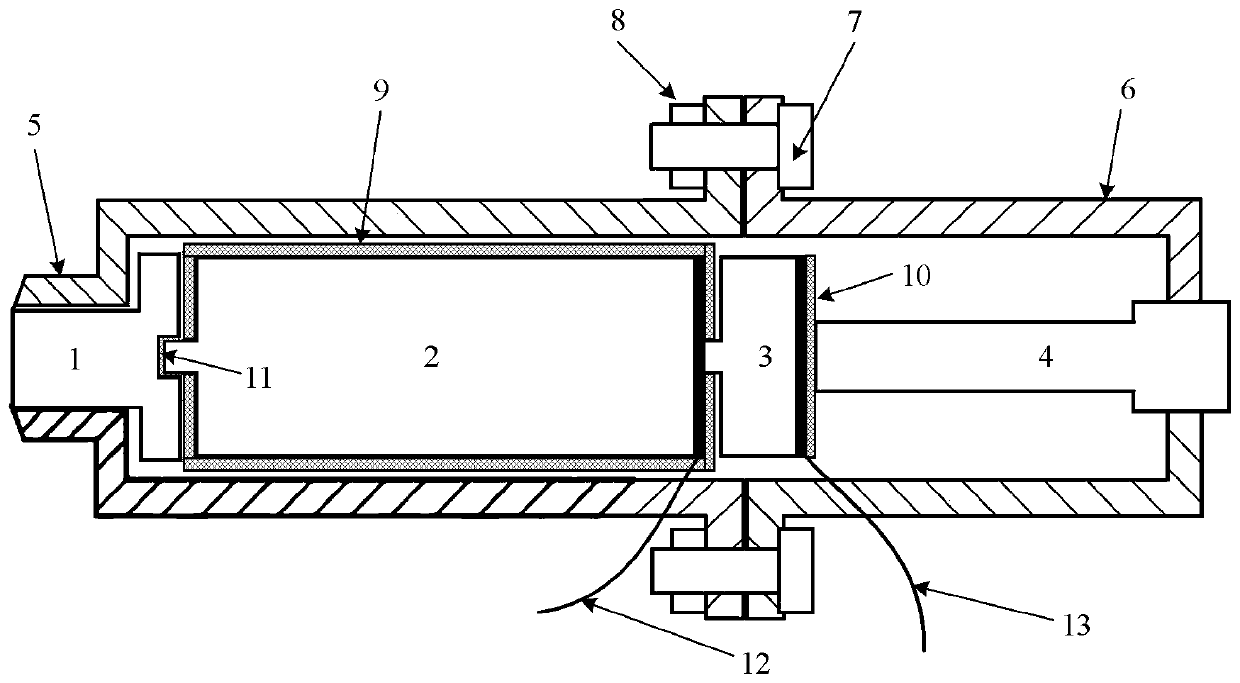

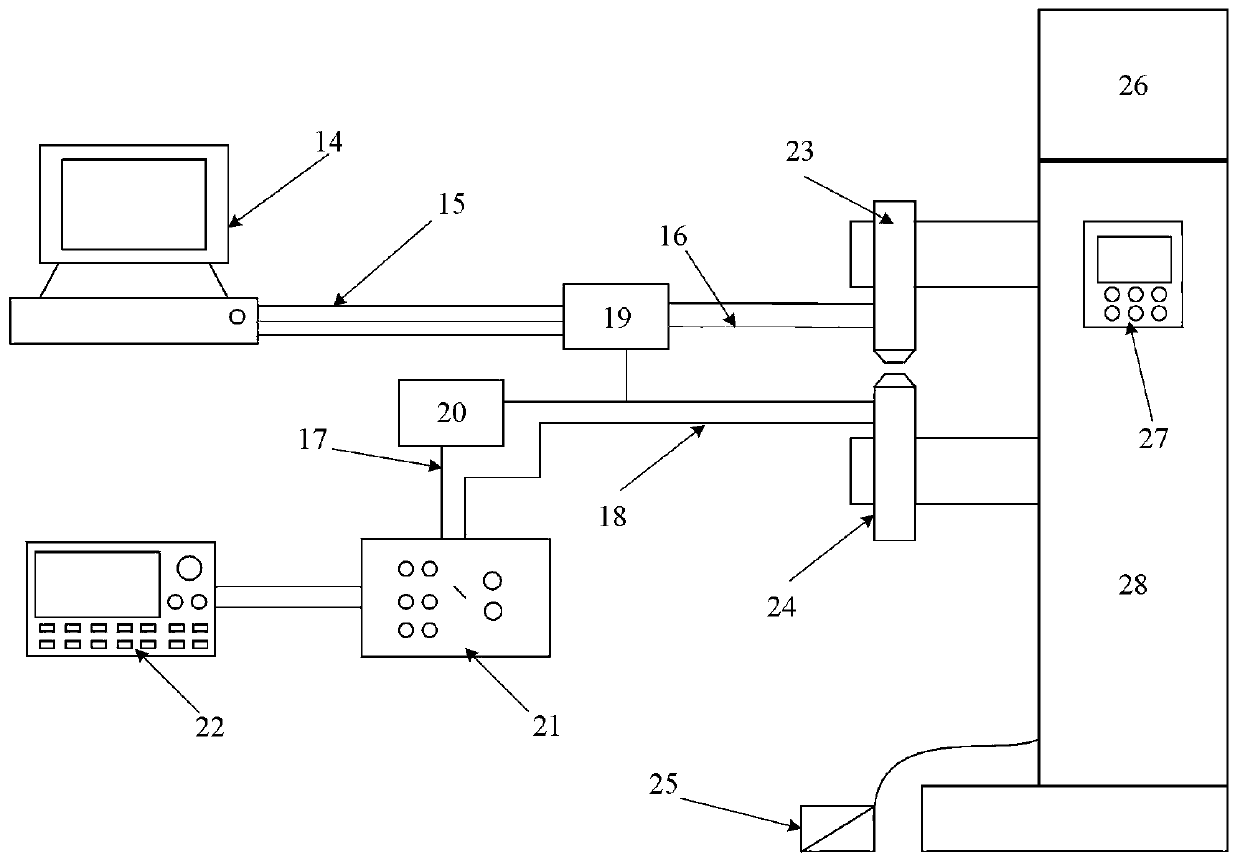

[0027] First, install the resistance spot welding electrode assisted by the piezoelectric actuator, select the length of the moving end to realize parallel pressure / series pressure, connect and fix the moving end 1 to the insulating layer 11, and insulate the piezoelectric actuator 2 from the outside The layer 9 is connected and fixed, the pressure sensor 3 is connected and fixed with the insulating layer 10, and the moving end 1 is connected with the insulating layer 11, the piezoelectric actuator 2 is connected with the outer insulating layer 9, and the pressure sensor 3 and the insulating layer 10 are composed of three parts. The coaxial connection is inserted into the ring electrode 5, and the moving tip 1 passes through the front end of the ring electrode. Connect the tail electrode 6 coaxially with the above components, connect and fix the two parts through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com