Welding head for radio frequency identification of electronic label sealing wire

An electronic label and radio frequency identification technology, applied in the field of electronic technology devices, can solve the problems of large overall size of the heat sink, the welding head is only suitable for a single piece of work, and cannot be packaged with an RFID chip, etc., to achieve force control accuracy and flexibility. High, low cost, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

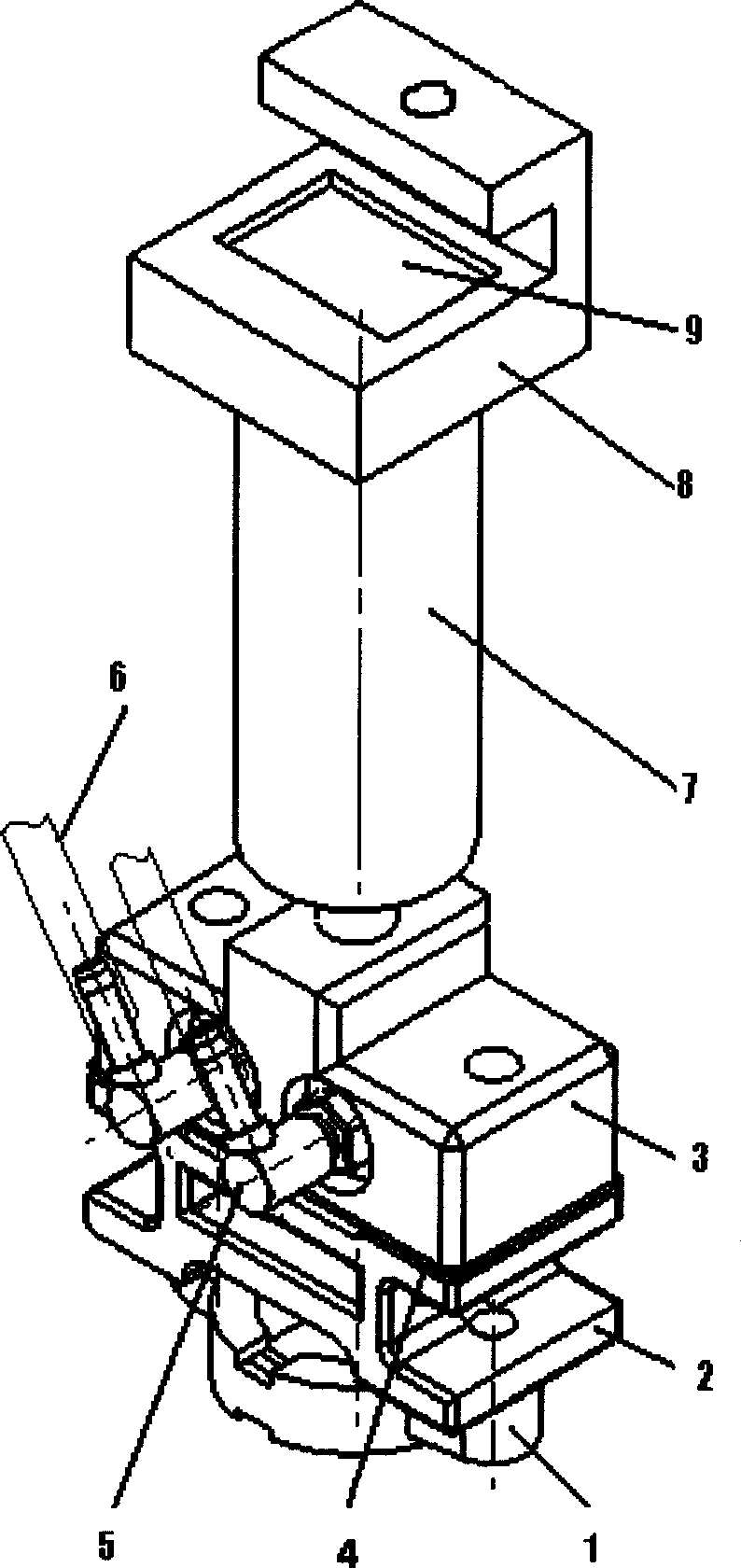

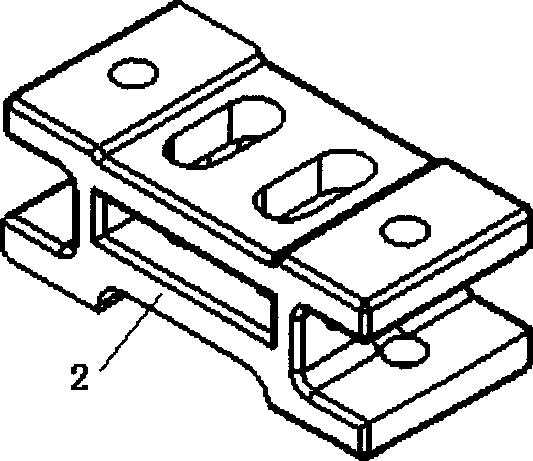

[0013] Such as figure 1 As shown, the present invention includes: a heating head 1, a radiator 2, a cylinder-piston connector 3, an air circuit joint 5, an air pipe 6, a cylinder 7, a base 8, and a permanent magnet 9. The heating head 1 and the radiator 2 are connected by bolts, and the mica gasket 4 is used for heat insulation between the two; the mica gasket 4 is used for heat insulation between the radiator 2 and the cylinder piston connector 3, and the bolts ; The cylinder piston rod connector 3 is connected to two air pipes 6 through the air joint 5, and the end of the cylinder 7 is set as a square hollow base 8, and a permanent magnet 9 is installed inside, which is fixed with the iron mounting surface by means of suction, and passed through Tight screw clamp.

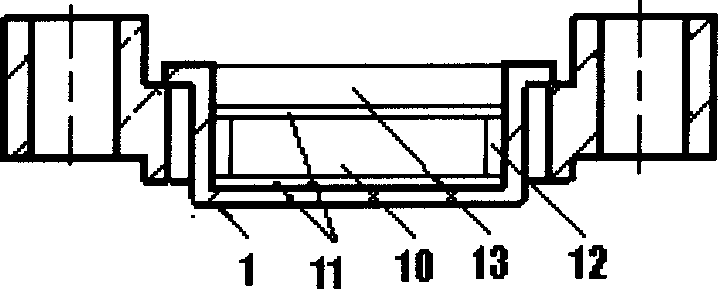

[0014] Such as figure 2 As shown, the heating head 1 is made of ceramic material, and a cylindrical PCT thermostatic element 10 is arranged inside, and thin aluminum sheets 11 are arranged on both bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com