Multi-nozzle 3D printer based on rotary platform

A 3D printer and rotating platform technology, applied in the field of 3D printing, can solve the problems of product difference, rough surface, difficult to meet requirements, etc., to achieve the effect of improving printing efficiency, increasing printing speed and saving printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The multi-nozzle 3D printer of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

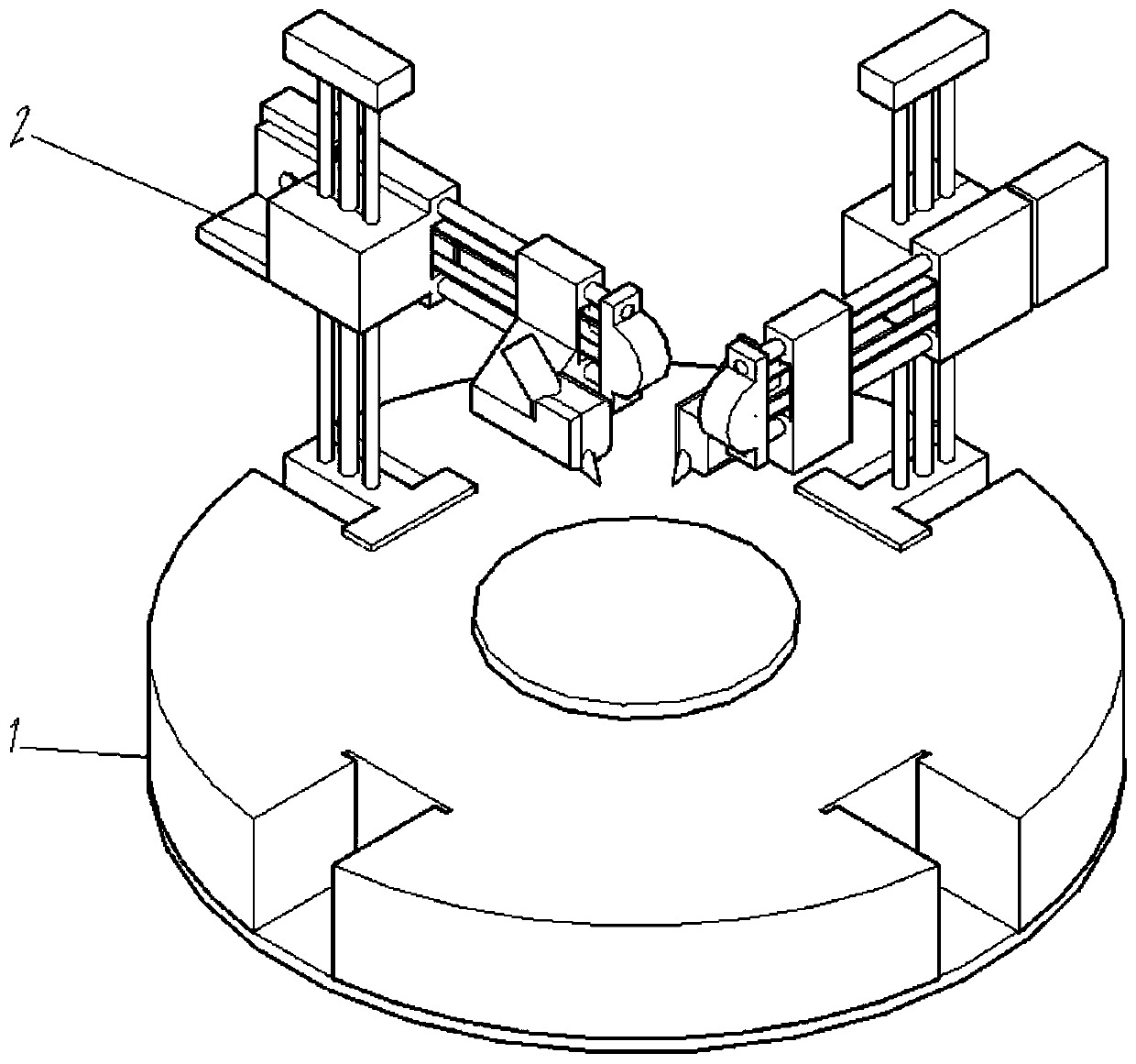

[0043] Such as figure 1 The multi-nozzle 3D printer shown includes a printer base 1 and two printing arms 2 installed on the base 1 .

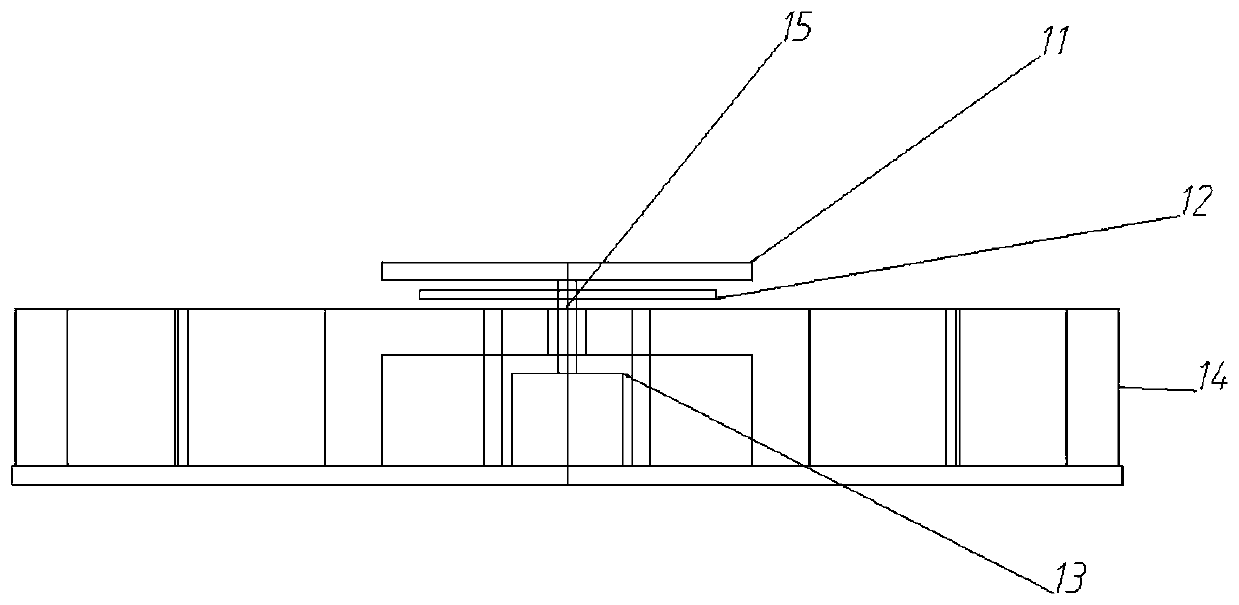

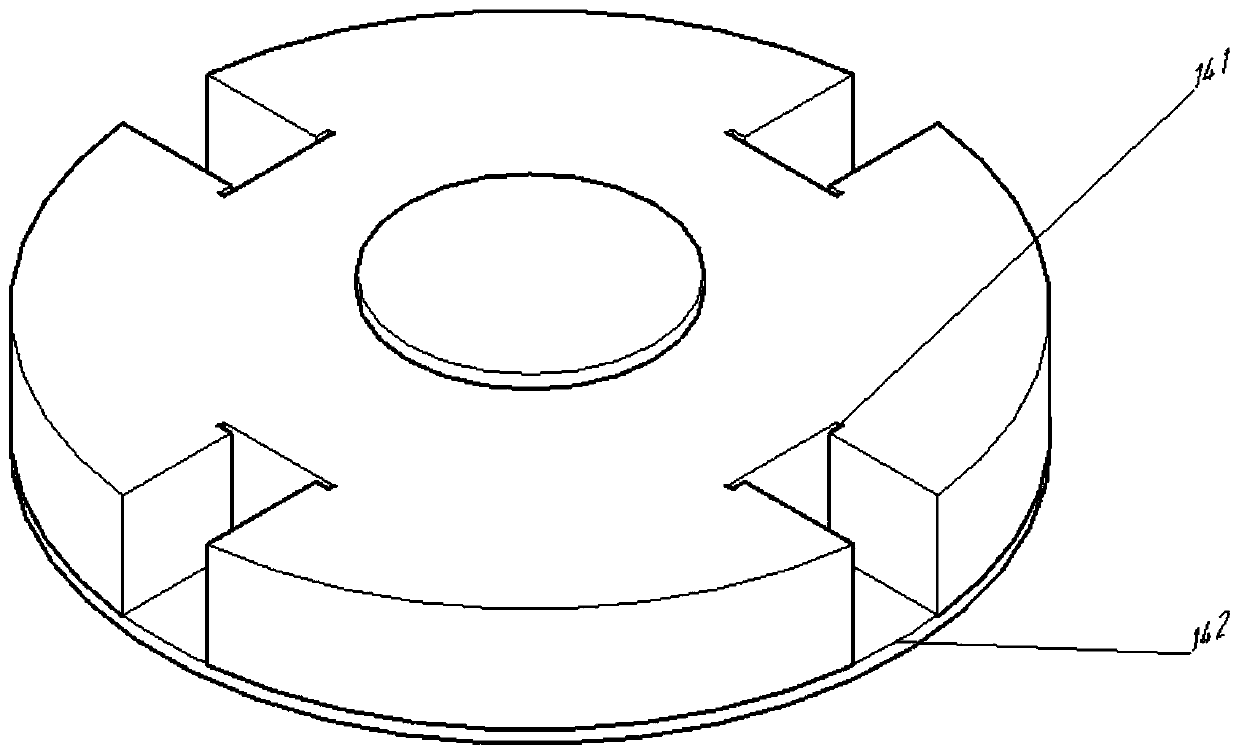

[0044] The structure of the printer base 1 is as figure 2 As shown, it includes a rotating platform 11 , a photoelectric encoder 12 , a first motor 13 , a base 14 and a spindle 15 . Specifically, such as image 3 As shown, the base 14 includes a first bottom plate 142 and a printing arm fixing plate 141 disposed on an upper surface of the first bottom plate 142 . Both the first bottom plate 142 and the printing arm fixing plate 141 are circular plates with the same diameter and arranged coaxially. The first bottom plate 142 has a number of through holes for connection, and the lower end surface of the printing arm fixing plate 141 has a number of screw holes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com