A kind of electromagnetic shielding composite material and preparation method thereof

A composite material, electromagnetic shielding technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of limited preparation and application, limited electromagnetic wave shielding effect, etc. Good electrostatic effect and the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

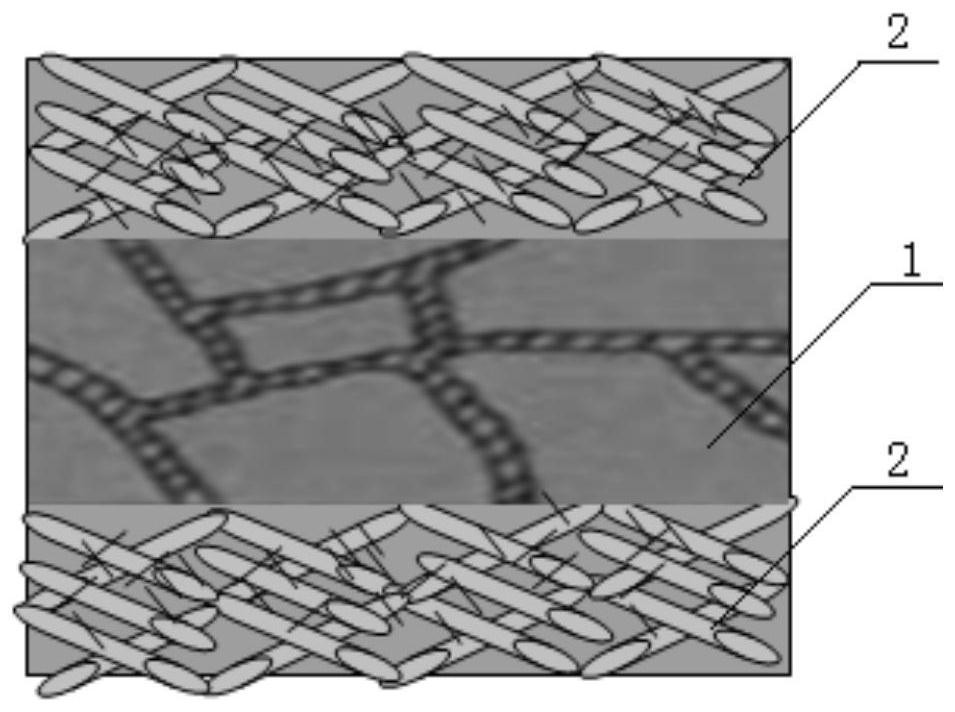

Image

Examples

Embodiment 1

[0032] The present invention comprises the steps:

[0033] (1) Add the spray liquid (5 mg / l) prepared by inorganic nanoparticles: carbon powder and solvent absolute ethanol into the spray device, and then align the nozzles of the spray device with the two sides of the polyurethane sponge respectively, start The spraying device sprays, after the spraying is completed, the solvent volatilizes, and the carbon powder adheres to the polyurethane sponge tendons.

[0034] (2) preparation contains the macromolecular polymer spinning solution (polymer concentration is 0.1g / ml in the spinning solution; polymer type is polyurethane) containing a certain amount of carbon nanotubes (weight concentration is 5%), solvent is three Chloromethane, and using traditional electrospinning method (solution flow rate 3ml / h, voltage 10kv, pole distance 20cm, time 20min) all prepare dense carbon nanotubes on both sides of the polyurethane sponge with inorganic nanoparticles obtained in (1) Reinforce t...

Embodiment 2

[0039] The present invention comprises the steps:

[0040] (1) Add the spraying solution (0.2mg / l) prepared by inorganic nanoparticle graphene and solvent acetone into the spraying device, then aim the nozzles of the spraying device at the two sides of the polyurethane sponge respectively, and start the spraying device Spraying, after spraying, the solvent volatilizes, and the inorganic nanoparticles are attached to the polyurethane sponge tendons.

[0041] (2) preparation contains the polymer spinning solution (polymer concentration is 0.2g / ml in the spinning solution; Polymer type is polyvinyl alcohol, and solvent is water, and using the traditional electrospinning method (solution flow rate 2ml / h, voltage 15kv, pole distance 30cm, time 30min), the polyurethane sponge with inorganic nanoparticles obtained in (1) is prepared with dense carbon nanotubes on both sides. The polymer single-layer nanofiber film is heated and dried (50°C, 6h), so as to obtain a sandwich carbon nan...

Embodiment 3

[0045] The present invention comprises the steps:

[0046] (1) Add the spraying solution (15 mg / l) prepared by inorganic nanoparticles ferric oxide and solvent hydrochloric acid into the spraying device, then align the nozzles of the spraying device with the two sides of the polyurethane sponge, and start the spraying device Spraying, after spraying, the solvent volatilizes, and the inorganic nanoparticles are attached to the polyurethane sponge tendons.

[0047] (2) prepare the polymer spinning solution (polymer concentration is 0.05g / ml in the spinning solution; the polymer type is polyacrylonitrile) containing a certain amount of carbon nanotubes (weight concentration is 8%), solvent For dimethylacetamide, adopt the traditional electrospinning method (solution flow rate 5ml / h, voltage 20kv, pole distance 15cm, time 25min) in (1) the two sides of polyurethane sponge with inorganic nanoparticles are all prepared Dense carbon nanotube-reinforced polymer single-layer nanofiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com