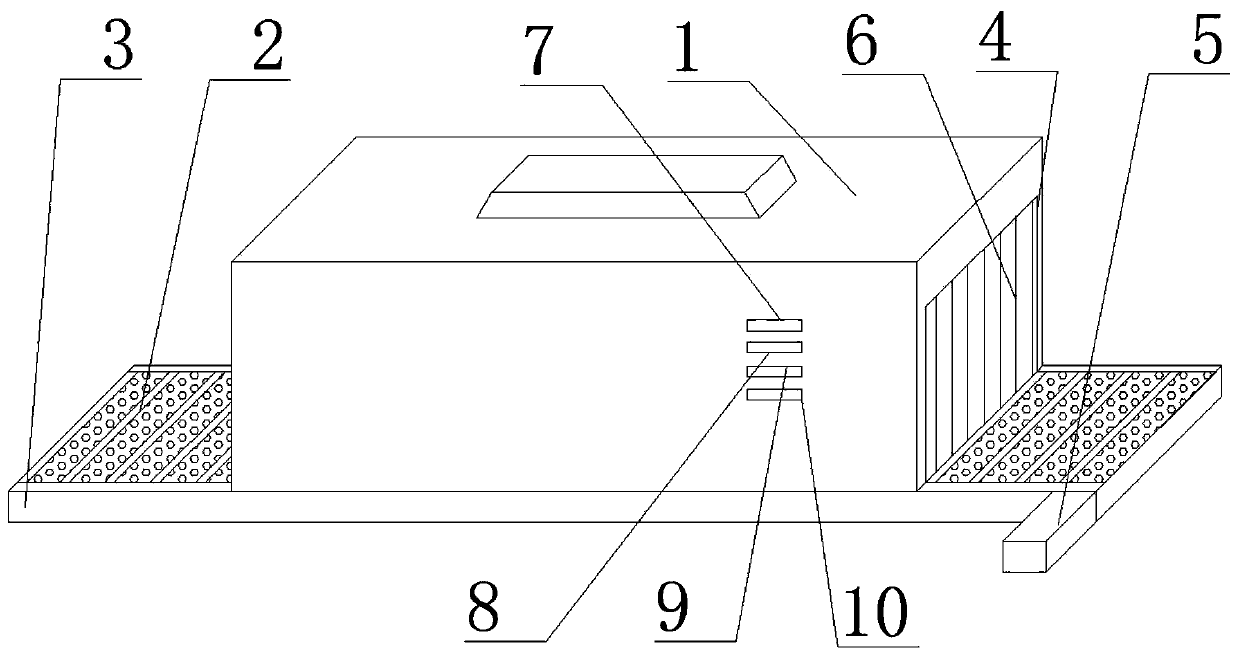

Self-service carwash with microbubble function

A car washing room and micro-bubble technology, applied in vehicle cleaning, vehicle maintenance, vehicle cleaning equipment and other directions, can solve the problems of affecting the living environment of surrounding people, increasing nearby humidity, wasting water, etc., reducing drying time, Increased utilization, increased geographic reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

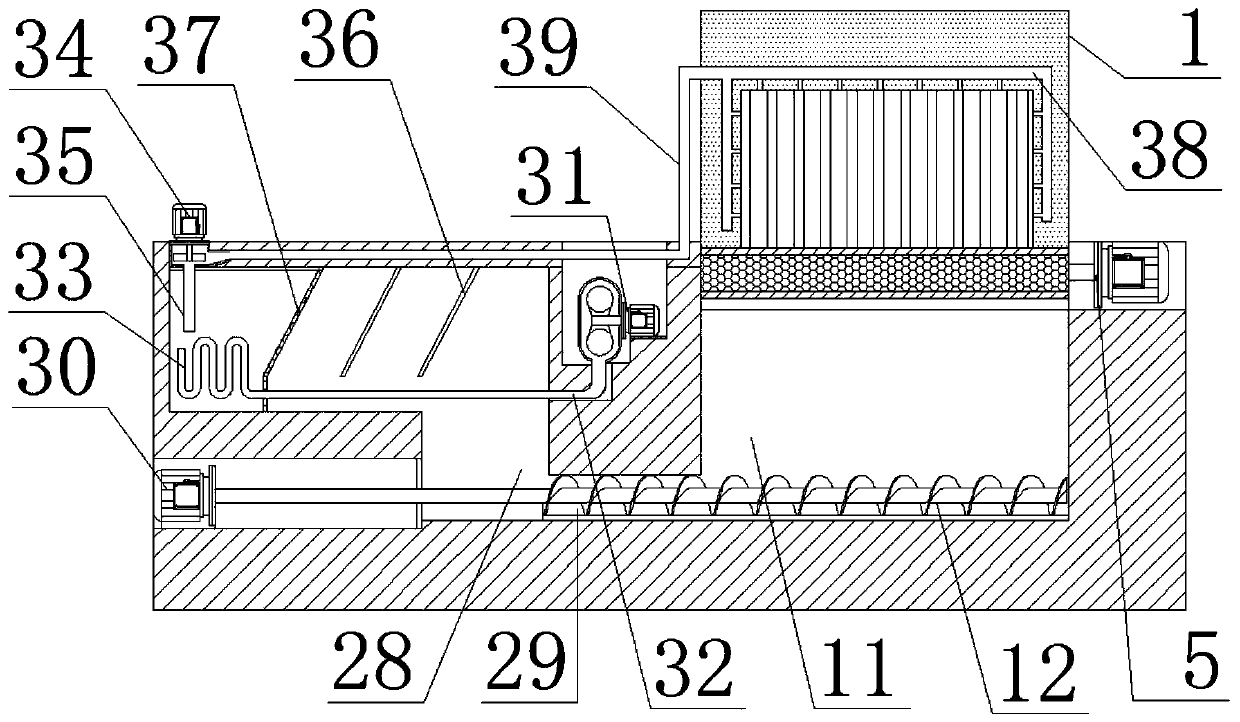

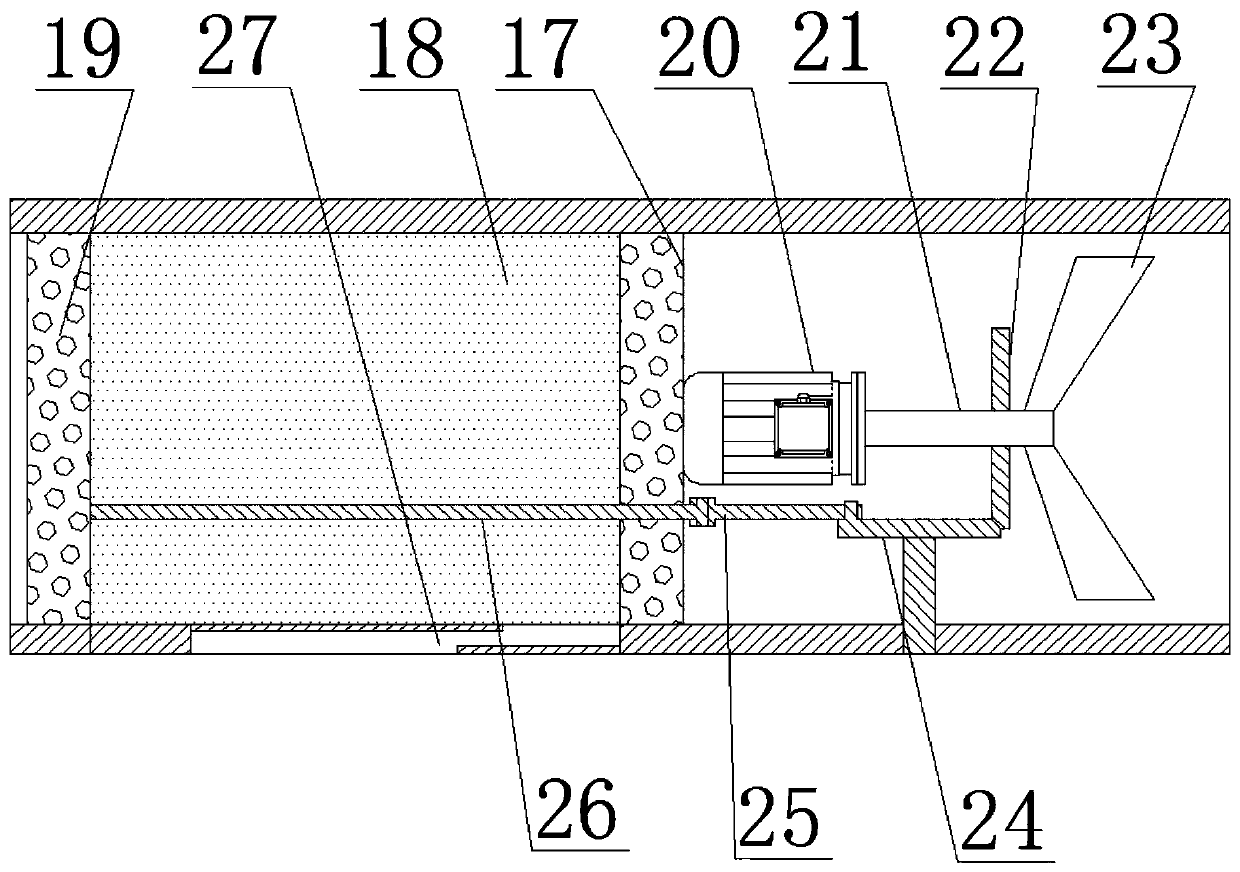

[0026] As a preferred embodiment of the present invention, one side of the spiral plate 12 is arranged at the bottom of the sewage pool 11, the other side of the spiral plate 12 is arranged on the inner side of the connecting pipe 29, and the outer surface of the spiral plate 12 is The diameter is equal to the inner diameter of the connecting pipe 29.

[0027] As a preferred embodiment of the present invention, the transmission shaft 13 is installed on both sides of the chassis 3 through a rotating shaft, and the conveyor belt 2 is sheathed on the outer side of the transmission shaft 13 .

[0028] As a preferred embodiment of the present invention, one end of the transmission shaft 13 is installed on the output shaft of the motor one 5 by bolts, and one end of the spiral plate 12 passes through one side of the purification pool 28 and is installed on the motor by bolts. Three 30 on the output shaft.

[0029] As a preferred embodiment of the present invention, one end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com