Soil ditch for purifying domestic wastewater and construction method thereof

A technology for purifying soil and domestic sewage, applied in the field of environmental engineering, can solve problems such as speeding up the movement of sewage, reducing the amount of sewage retained, and achieving the effect of expanding the geographical scope of use and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a detailed description of the embodiments of the present invention, giving detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

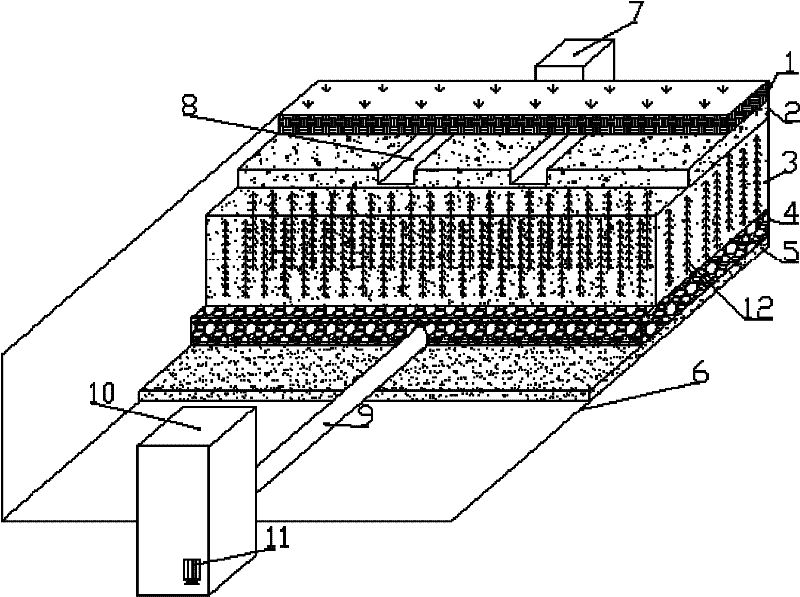

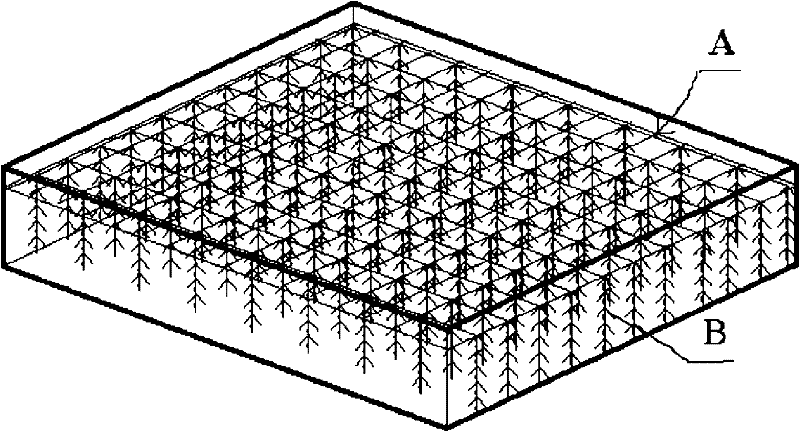

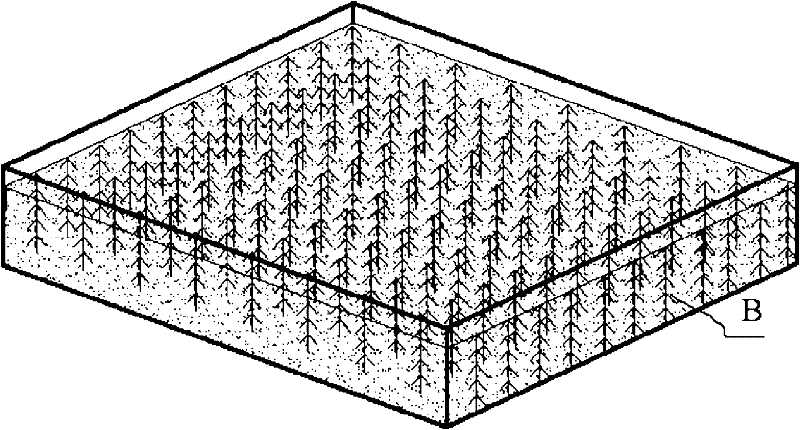

[0030] Such as figure 1 As shown, this embodiment includes: water inlet mechanism, covering soil layer 1, mixing layer 2, soil layer 3, gravel layer 4, fine sand layer 5, water-resisting layer 6 and drainage mechanism, wherein: covering soil layer 1, mixing layer 2 , soil layer 3, gravel layer 4, fine sand layer 5 and water barrier layer 6 are arranged sequentially from top to bottom, the water inlet mechanism is connected with the mixed layer 3, and the drainage mechanism is connected with the gravel layer 5 and the fine sand layer 6.

[0031] The water inlet mechanism includes: a water inlet pool 7 and several water distribution tanks 8, wherein: the outlet of the water inlet pool is connected with the water distribution tank, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com