Anti-counterfeit rubber cap and use method

A technology of rubber caps and two-dimensional codes, applied in the direction of caps with auxiliary devices, sealing parts with auxiliary devices, etc., to achieve the effect of improving the accuracy of identification, improving the level of anti-counterfeiting and the difficulty of counterfeiting, and facilitating the operation of authenticity identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

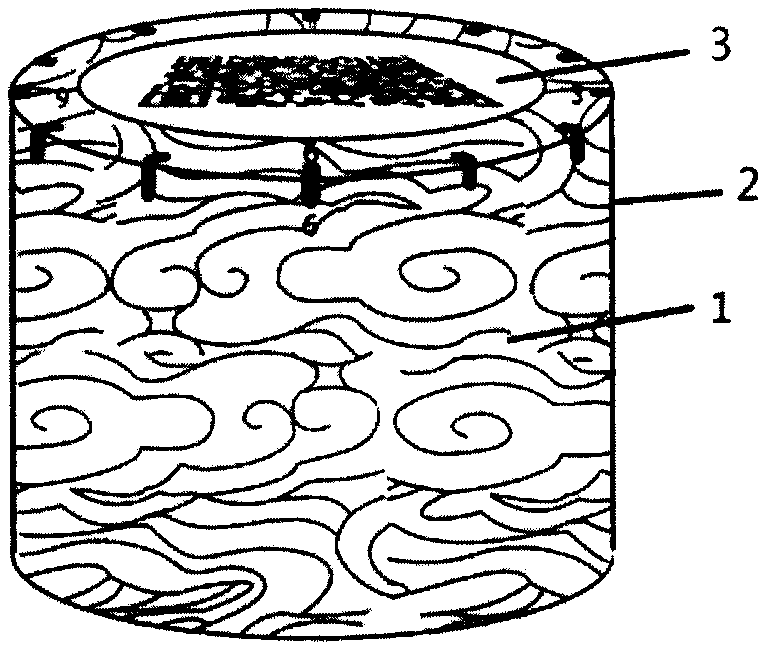

[0023] As can be seen that Fig. 1 is the structure schematic diagram of the present invention, a kind of three-dimensional anti-counterfeit rubber cap 1, this three-dimensional rubber cap 1 is made up of cap wall 2, cap top 3 two parts, selects the good transparent plastic base material (such as PVC with heat-shrinkable property) , PE, etc.) made.

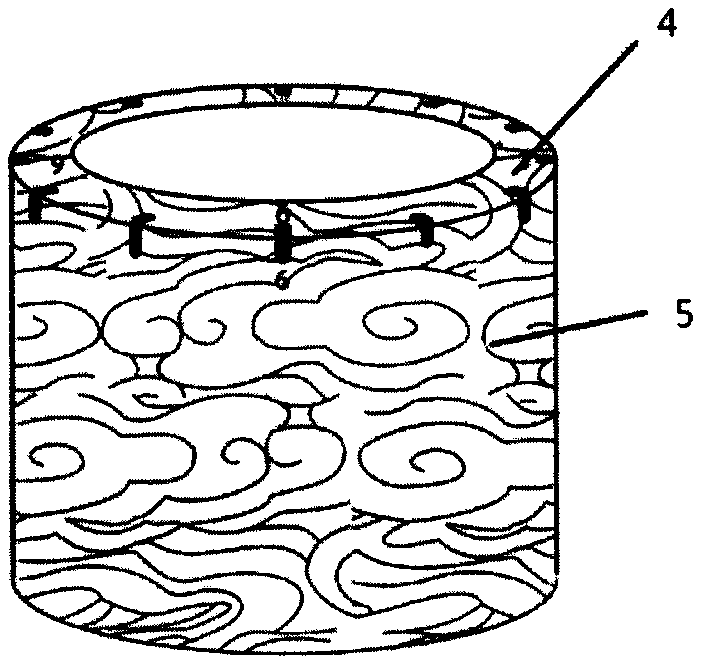

[0024] like figure 2 It is a schematic diagram of the cap wall structure of the rubber cap of the present invention. It can be seen that the cap wall 2 is composed of a side wall 4 and a top receiving part 5. After molding, the 4 side walls are cylindrical, and the top receiving part 5 is circular. The side wall 4 and the top receiving portion 5 form an angle of 90 degrees.

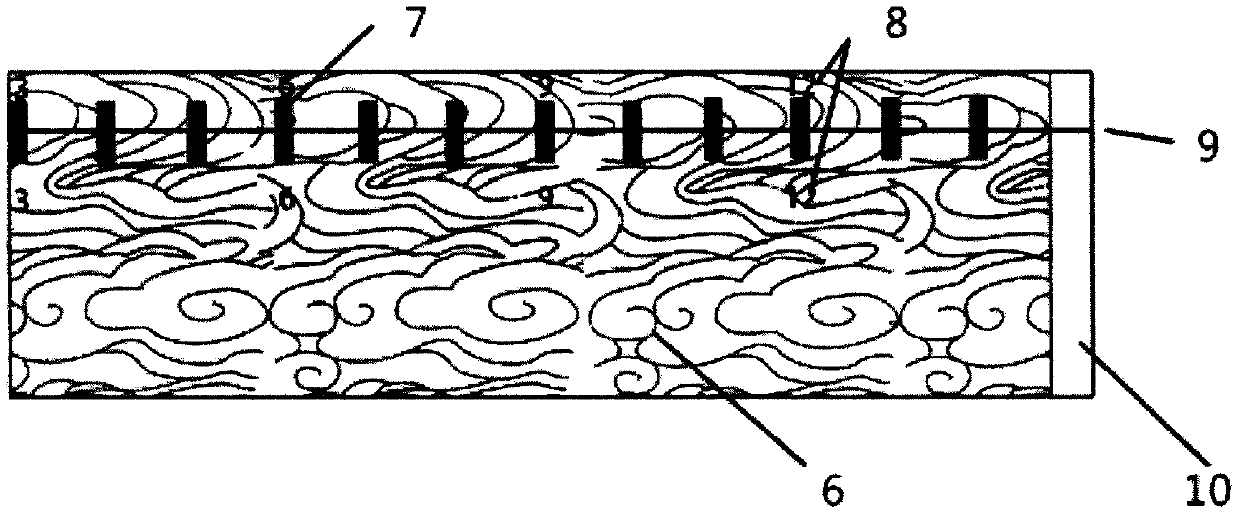

[0025] like image 3 It can be seen from the schematic diagram of the unfolded structure of the base material of the cap wall of the present invention that the base material of the cap wall 2 wraps the rubber cap through the sticking area 10, and the base m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com