High polymer self-adhesion waterproof roll and production method thereof

A self-adhesive waterproof membrane and polymer technology, applied in the direction of non-polymer adhesive additives, adhesives, earth square drilling, etc., can solve the problems of anti-adhesive film waste, increase production costs, increase production process, etc., to achieve long-term Stable waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

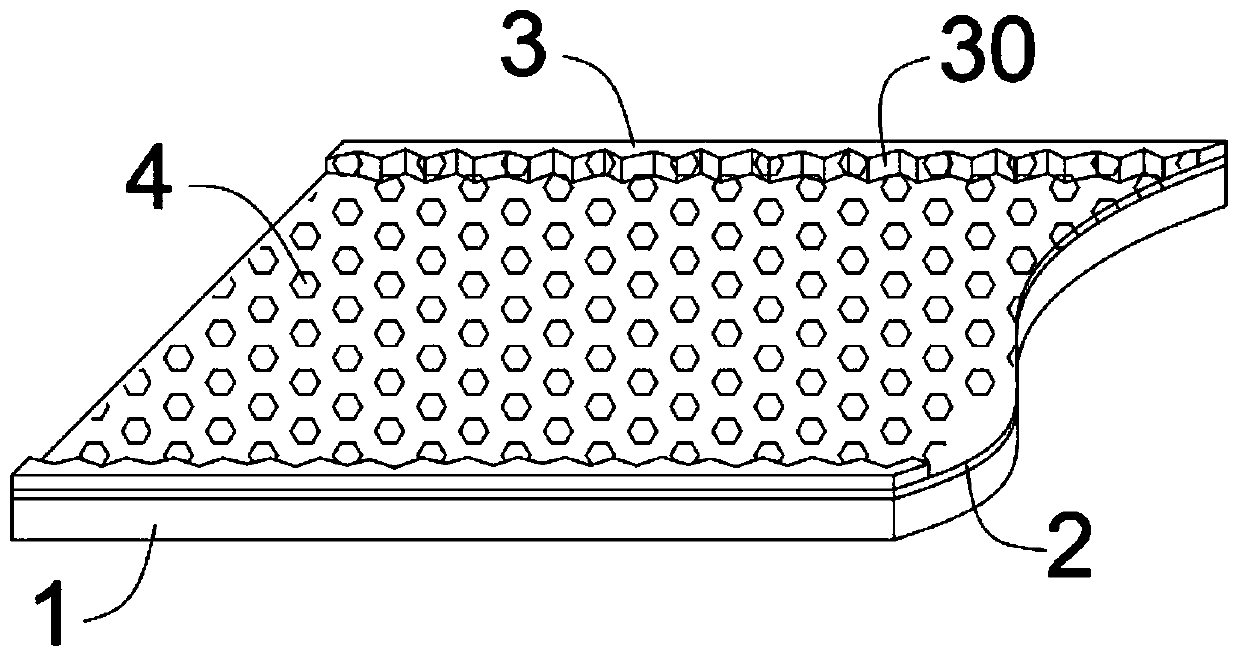

[0031] The polymer self-adhesive waterproof membrane of this embodiment includes a high-density polyethylene waterproof board 1 , a self-adhesive layer 2 , a sand grain layer 4 and a limiting strip 3 .

[0032] The self-adhesive layer 2 is coated on one side of the high-density polyethylene waterproof board 1, and 500 g of adhesive is evenly coated on the surface of the high-density polyethylene waterproof board 1 per square meter. Wherein, the adhesive is composed of the following components in parts by weight: 16 parts of carbon fiber, 42 parts of SEBS, 29 parts of petroleum resin, 24 parts of naphthenic oil, 0.8 part of antioxidant, and 3 parts of calcium carbonate.

[0033] There are two limit strips 3, and the two limit strips 3 extend along the length direction of the high-density polyethylene waterproof board 1. The length direction referred to here is also the circumferential direction of the upper and lower edges of the waterproof membrane, and it is also the direction...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that in this embodiment, 300 g of adhesive is evenly coated on the surface of the high-density polyethylene waterproof board per square meter. Wherein, the adhesive is composed of the following components in parts by weight: 18 parts of carbon fiber, 46 parts of SEBS, 33 parts of petroleum resin, 26 parts of naphthenic oil, 1.3 parts of antioxidant, and 5 parts of calcium carbonate.

Embodiment 3

[0038]The difference between this embodiment and Embodiment 1 is that in this embodiment, 420 g of adhesive is evenly coated on the surface of the high-density polyethylene waterproof board per square meter. Wherein, the adhesive is composed of the following components in parts by weight: 17 parts of carbon fiber, 44 parts of SEBS, 31 parts of petroleum resin, 25 parts of naphthenic oil, 1 part of antioxidant, and 4 parts of calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com