Flue gas treatment device and boiler system

A flue gas treatment and flue gas technology, which is applied in the field of flue gas treatment devices and boiler systems, can solve the problems of large renovation of flue gas emission systems and boiler systems, high investment costs, poor effect and stability of electrostatic precipitators, and the like. Smooth and effective dust removal and denitration treatment, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only the technical solutions of the present invention. Some, but not all, embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present invention.

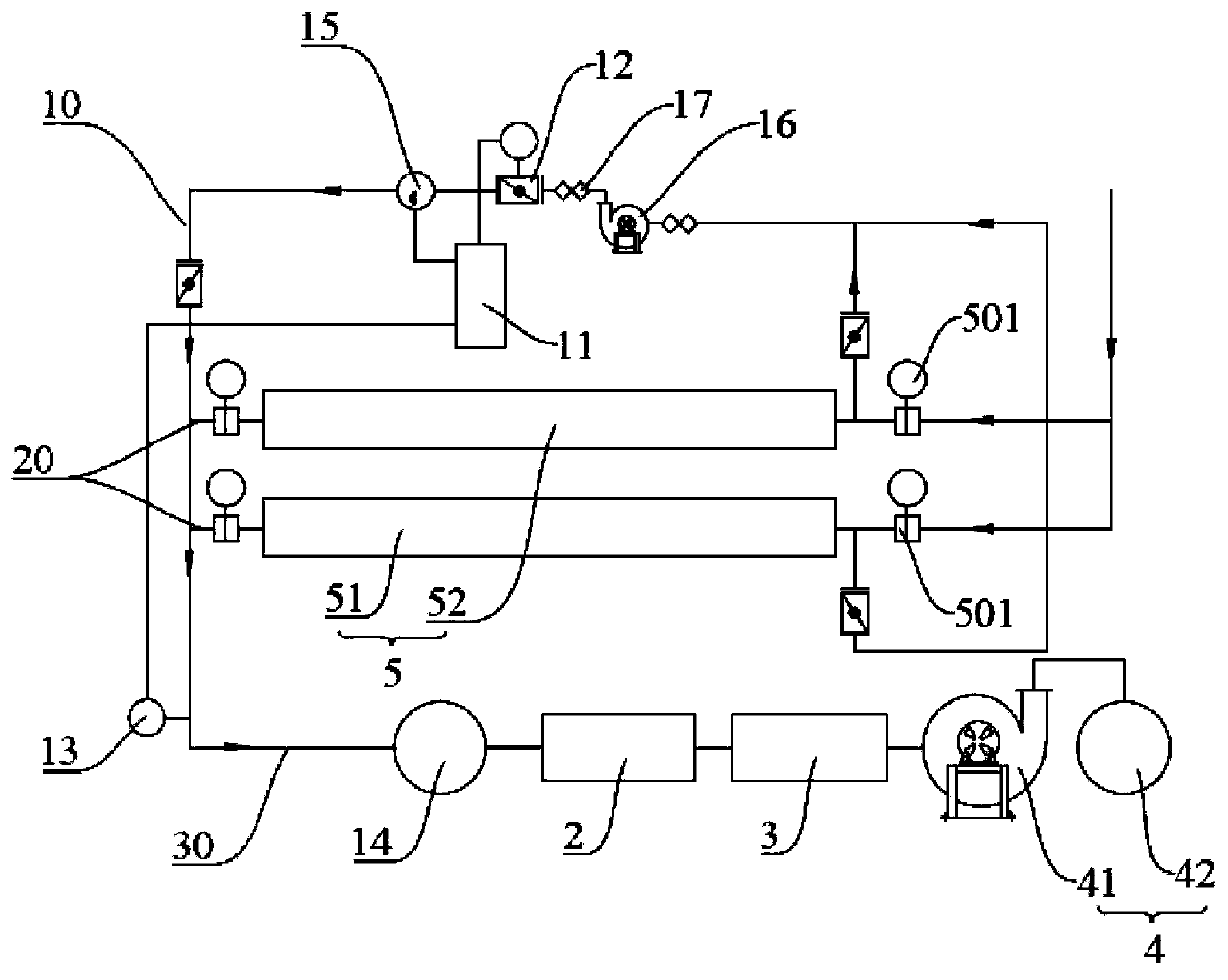

[0028] Such as figure 1 As shown, the present embodiment provides a boiler system, the boiler system includes a boiler assembly 5, the boiler assembly 5 is provided with an air inlet end and an air outlet end, the unheated flue gas enters through the air inlet end, and inside the boiler assembly 5 After heat exchange, it is discharged to the atmospher...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap