System and method for measuring motor bearings consumption of railway vehicles

一种电机轴承、轨道车辆的技术,应用在机械轴承测试、轴承、轴和轴承等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

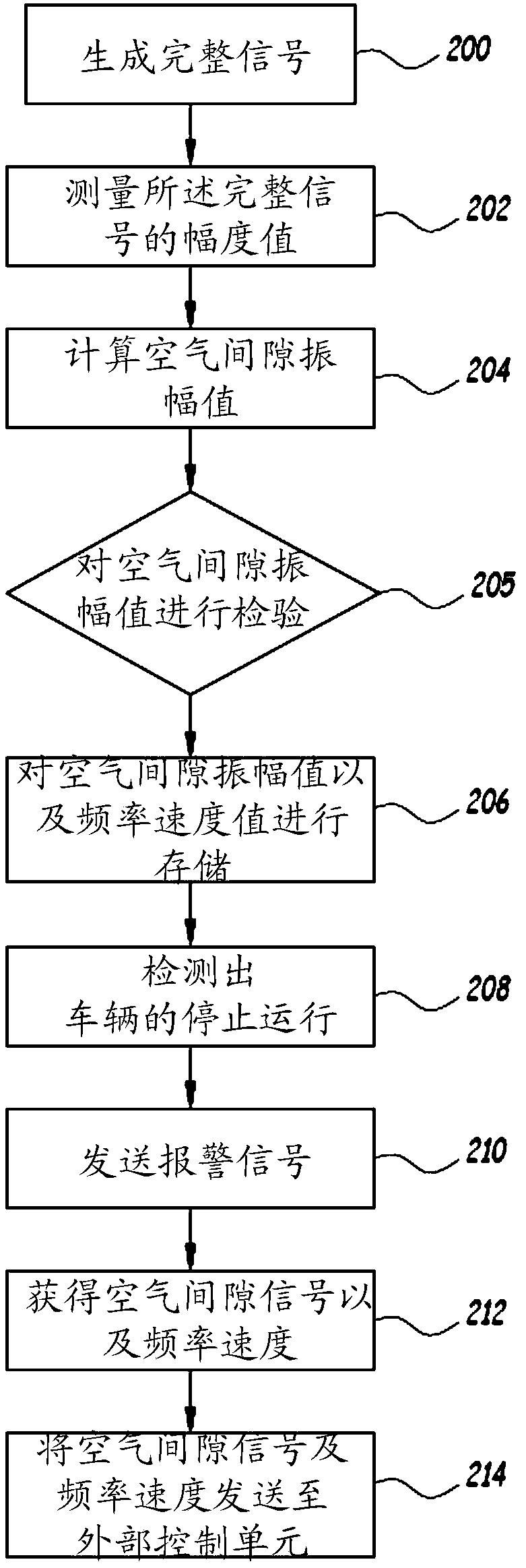

[0026] Briefly, the system of the invention comprises: a tone wheel fixed to the motor rotor shaft of a rail vehicle, which rotates under the action of a plurality of bearings; and a speed sensor fixed to the stationary part of the motor itself and facing said tone wheel .

[0027] If the bearings start to wear out due to the rotational movement of the shaft, the shaft will move radially towards the fixed part of the motor, causing the tone wheel to move towards or away from the transducer.

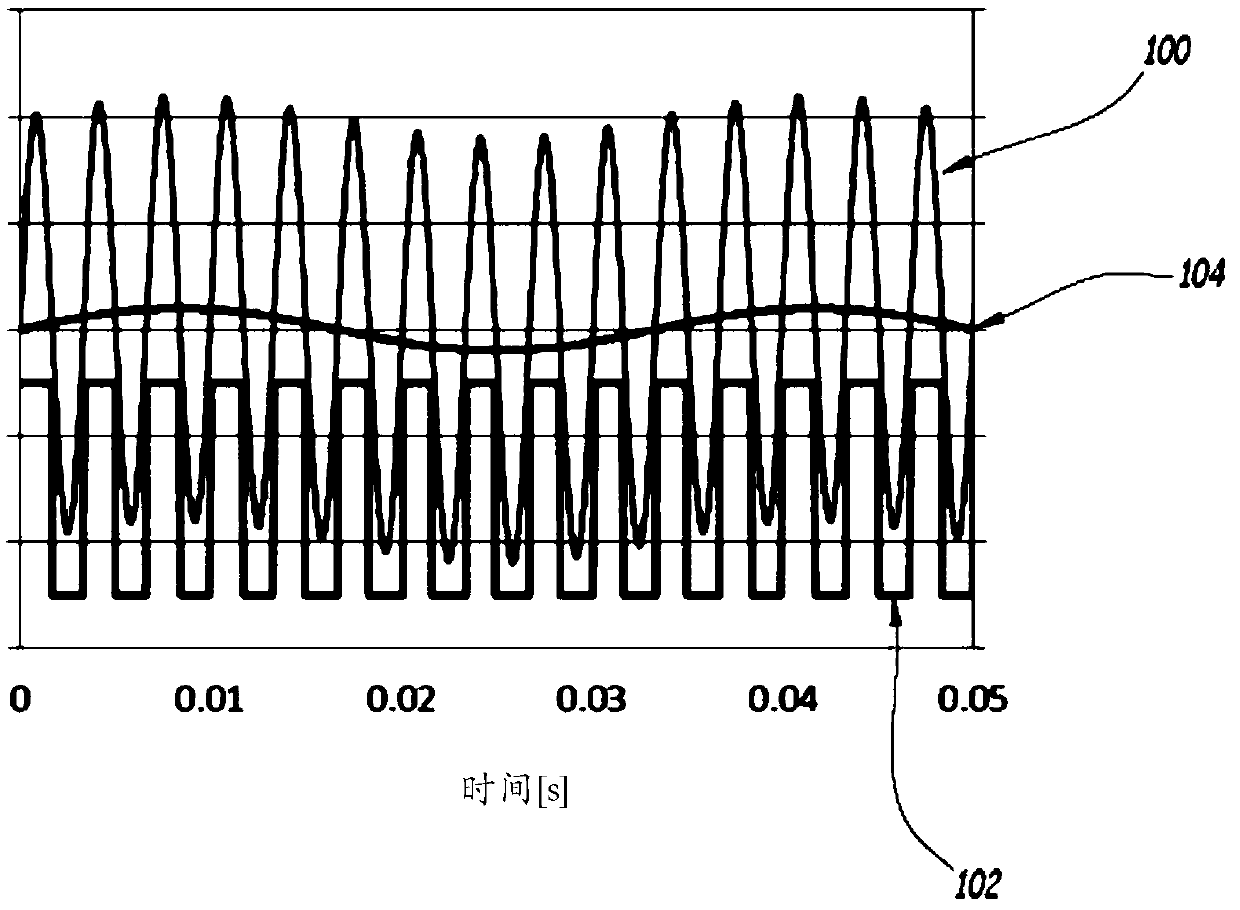

[0028] It is known that the vibration of the rotor produces an air gap variation between the teeth of the tone wheel and the sensor, which produces a modulation in the sine wave measured by the sensor.

[0029] In fact, said sensor is commonly used in prior art systems to indirectly measure the speed of a rail vehicle by measuring the speed of a tonewheel which produces a quasi-sine wave as the teeth and grooves of the tonewheel alternately pass in front of it.

[0030] In prior art syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com