PCB welding defect detecting method based on depth information

A technology for PCB board and welding defects, applied in the field of electronic component detection, can solve the problems of slow processing speed, excessive data volume, large false detection rate, etc., to reduce false detection rate, reduce data volume, and low lighting conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

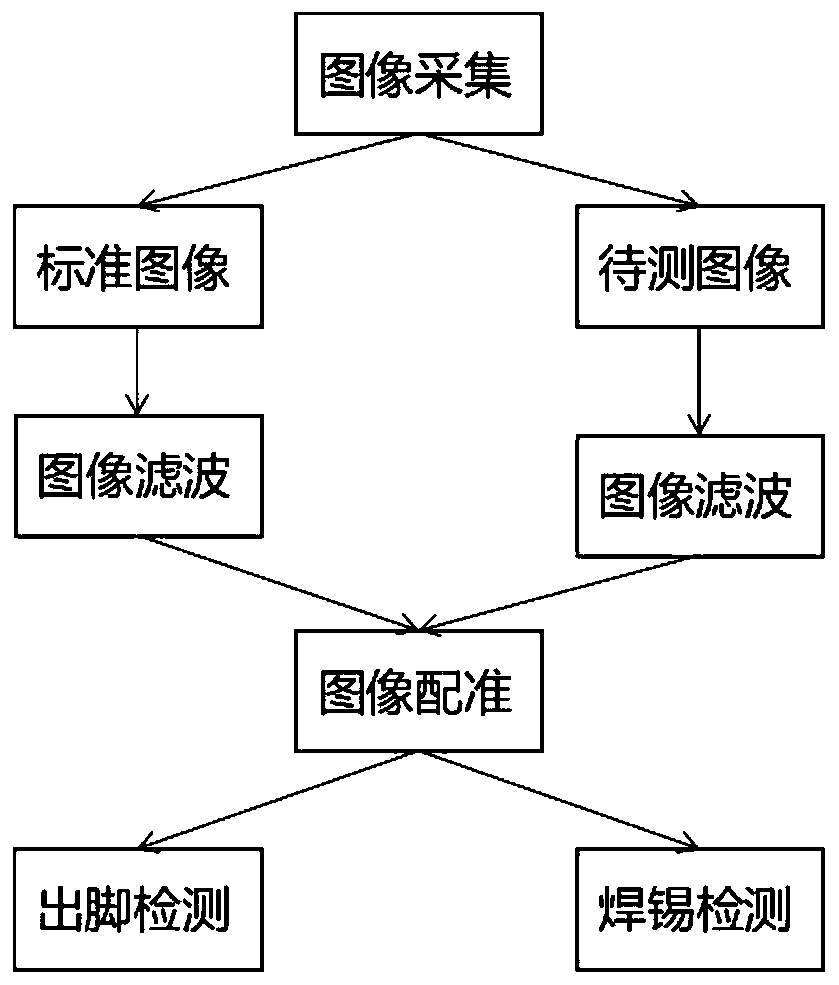

[0021] like figure 1 Shown, a kind of PCB board welding defect detection method based on depth information, described method comprises the following steps:

[0022] Collect the depth data of the welding area of the PCB board to be tested and the welding area of the standard PCB board respectively, use the line laser to scan the front and back of the standard PCB board, and collect the depth data of the front and back sides of the board;

[0023] According to the depth data of the welding area of the two PCB boards, corresponding depth images are generated respectively;

[0024] Obtain the standard welding image according to the depth image of the standard PCB board, obtain the welding image to be tested according to the depth image of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com