Wafer adsorption device capable of preventing heat conduction

An adsorption device and heat conduction technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as temperature unevenness and wafer processing, and achieve the effect of reducing contact area, avoiding temperature changes, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

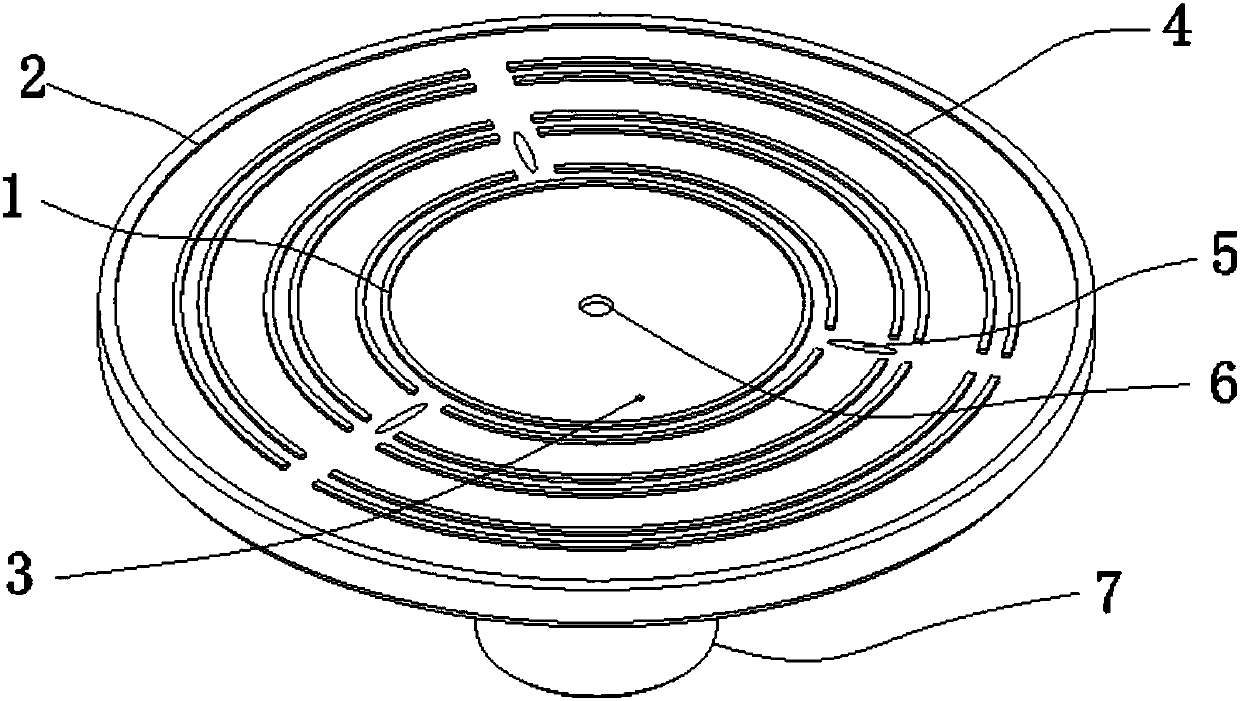

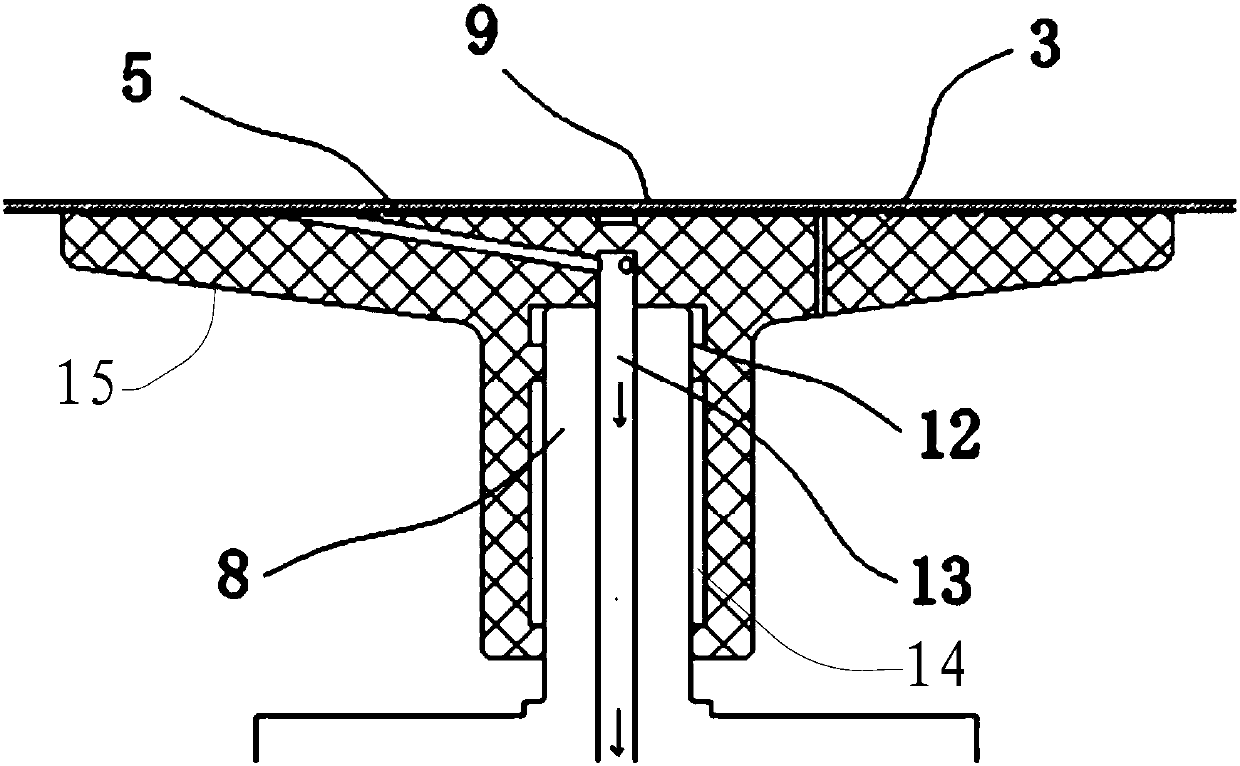

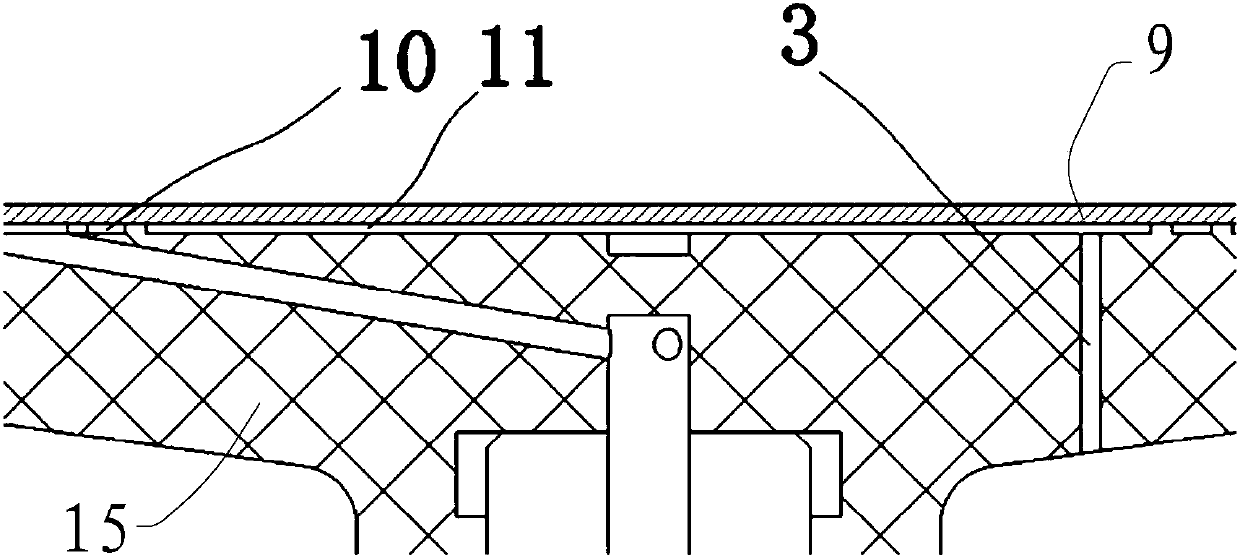

[0019] Such as Figure 1~3 As shown, the present invention includes a wafer carrier 15, which is connected to the motor shaft 8 of the motor, and the wafer 9 is driven to rotate by the motor.

[0020] The axial cross-section of the bearing table 15 is "T" shape, and the lower part of the bearing table 15 is the suction cup neck 7 connected with the motor shaft 8, and the inner hole wall of the suction cup neck 7 is provided with two rings up and down in the axial direction. shaped boss 12, the motor shaft 8 is inserted into the inner hole of the sucker neck 7, and is only connected with the annular boss 12; each annular boss 12 is formed by extending radially inward from the inner hole wall of the sucker neck 7 A non-contact cavity 14 is formed between the other parts of the hole wall except the annular boss 12 and the motor shaft 8 to reduce heat conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com