Packaging shell and battery

A technology for packaging shells and batteries, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of increased cell packaging volume, low cell energy density, and multiple volumes, and achieves improved volumetric energy density. Simple and reliable process, strong effect of hardness and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present application will now be described in detail with reference to the accompanying drawings, but the description is only exemplary and not intended to limit the protection scope of the present application.

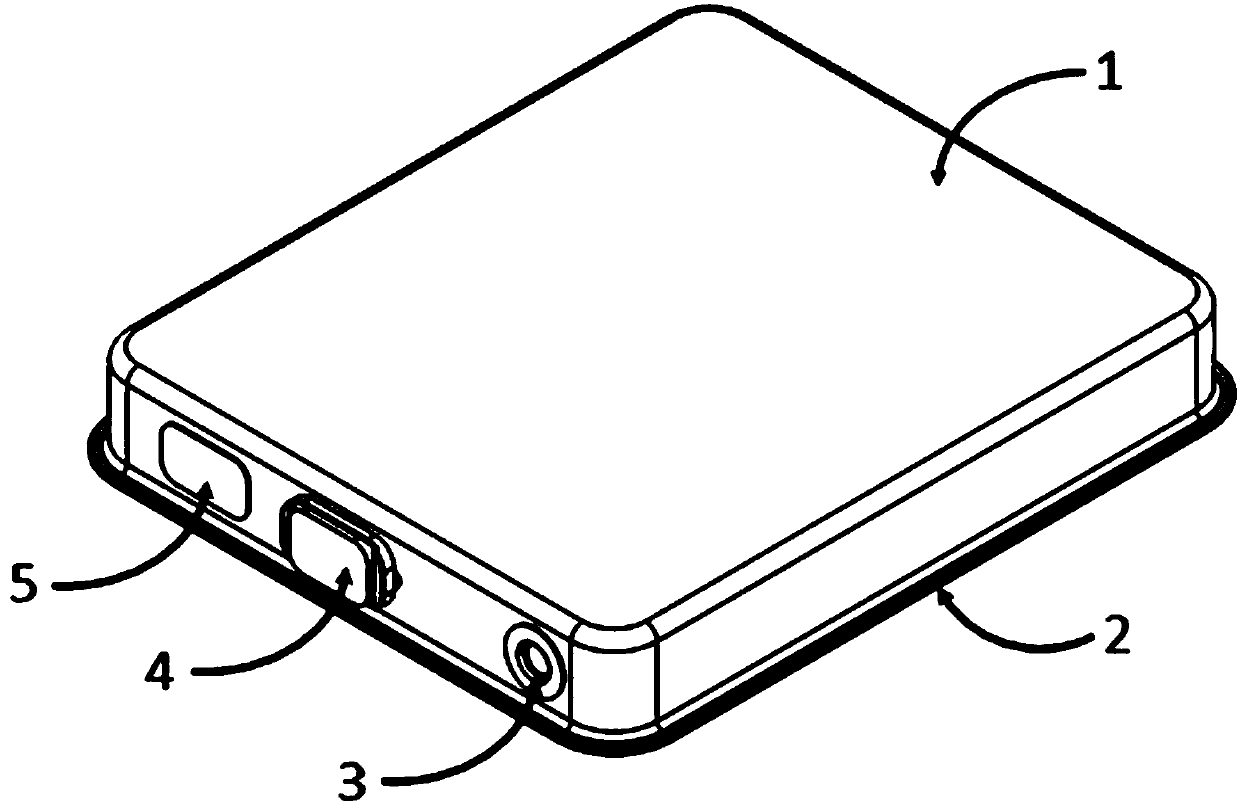

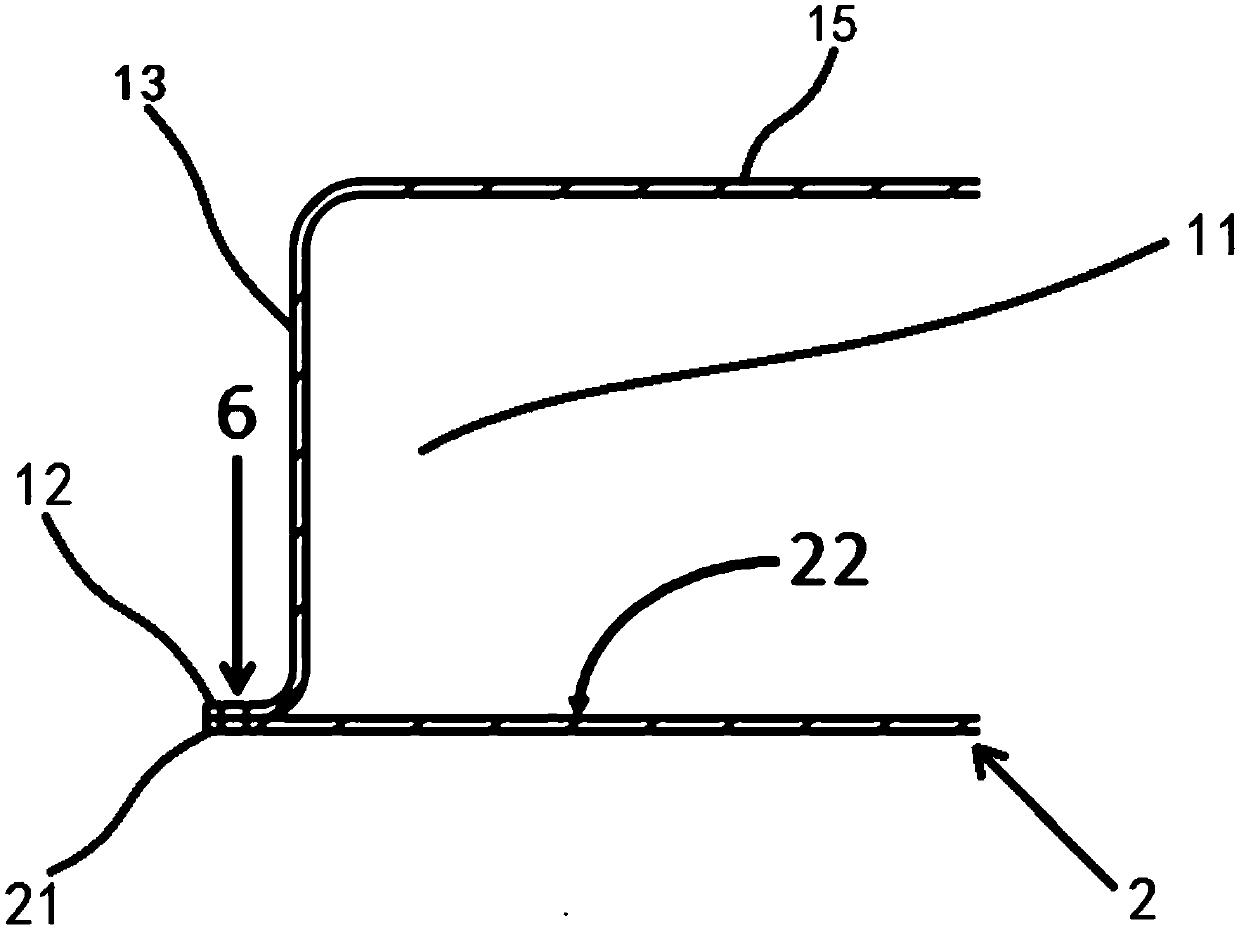

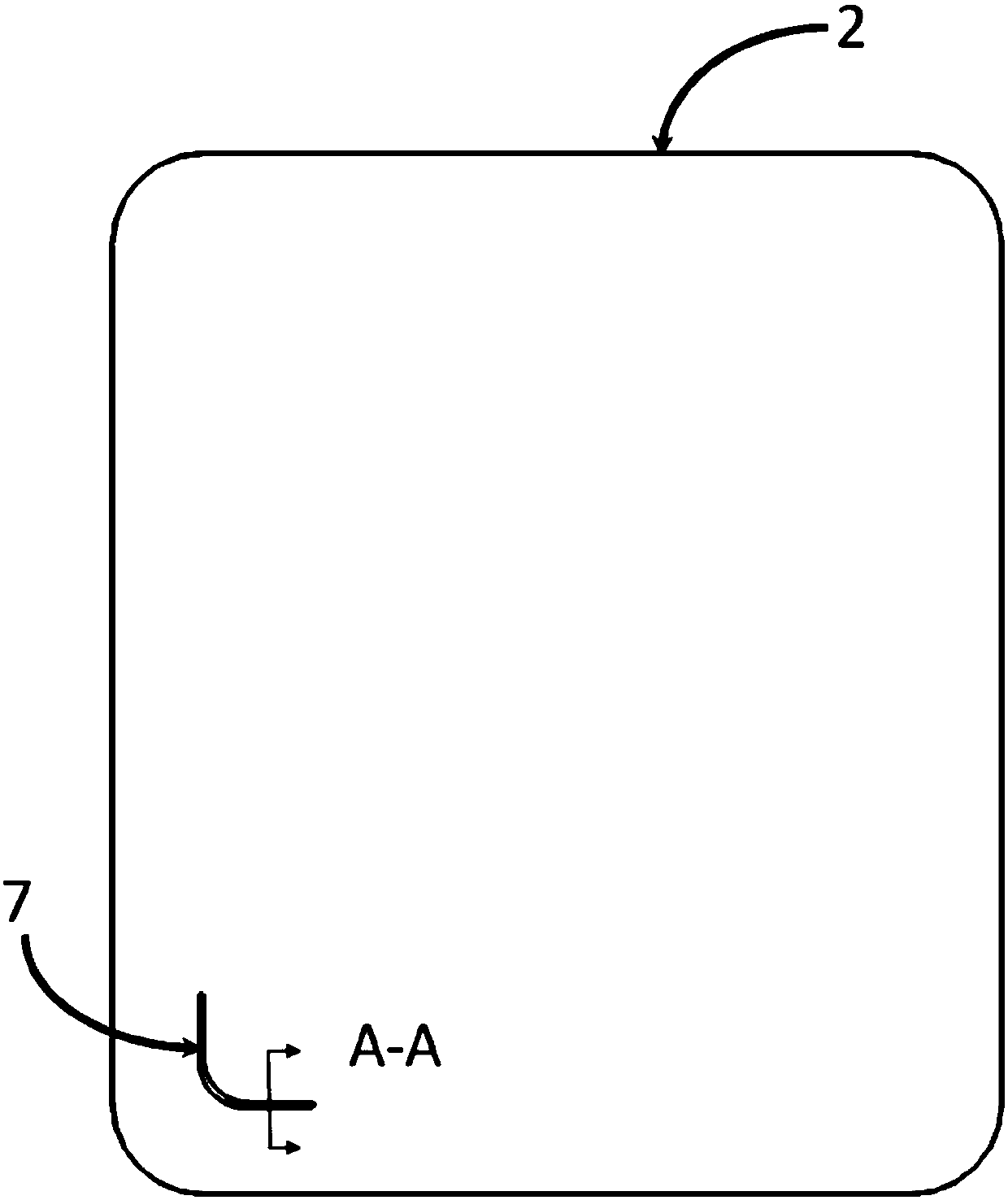

[0029] refer to figure 1 and figure 2 , In one embodiment, the present application provides a packaging case for a battery, comprising: a first casing 1, the first casing 1 includes a top 15 and a first side wall 13, and the first side wall 13 extends from the top 15 Extending downwards, the first side wall 13 has a first flange 12 extending outward, and the first side wall 13 surrounds an opening 11; and the second housing 2, the second housing 2 includes a middle part 22 and a The second flange 21 extending outward from the part 22; wherein, the middle part 22 is used to cover the opening 11, and the material of the first shell 1 and the second shell 2 is alloy. The packaging case of the present application hermetically joins the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com