Process for reducing the amount of mixed phases during concentration of milk streams

A technology of mixed phase and dairy products, applied in the field of skim milk to reduce the generation of mixed phases, concentrated milk flow, can solve problems in use and other problems, and achieve the effects of reduced loss, low cost, and low dry matter quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

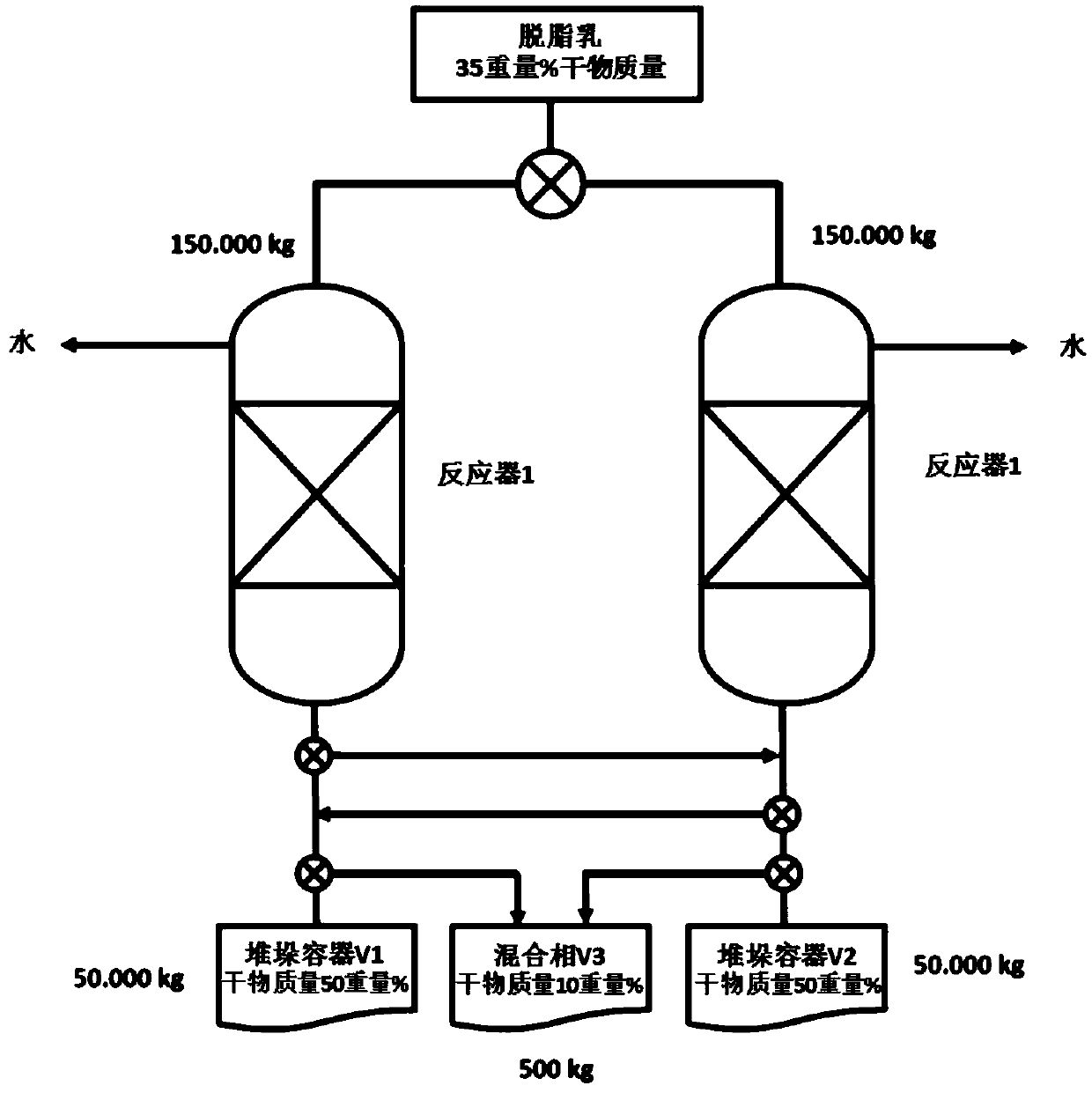

[0046] Comparative example V1 was repeated, however after 9 hours of operation the power of the first reactor was increased to produce a concentrate with a dry matter mass of 52.5%, which was mixed with the concentrate already present in the collection vessel so that at the end of the 10 hour run period The amount of dry matter amounts to 51.2% by weight.

[0047] After closing the first reactor and directing the milk flow to the second evaporator, the first reactor is rinsed with water as described above, while the concentrate, heavily diluted with the rinse water, is directed to the first collection vessel until the dry matter mass is reduced again to 50 wt. %. Only then is the diluted concentrate directed to a second collection vessel until the dry matter mass begins to be less than 15% by weight. At this point, the severely diluted concentrate is immediately directed to a third collection vessel, whereupon 500 kg of mixed phase are collected with a dry matter content of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com