Multifunctional automobile whole-line installing robot

A wire-mounted, multi-functional technology, applied in the field of robots, can solve problems such as single function and inability to realize clamping, and achieve the effects of improving work efficiency, improving precise control of clamping caliber, and preventing high temperature fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

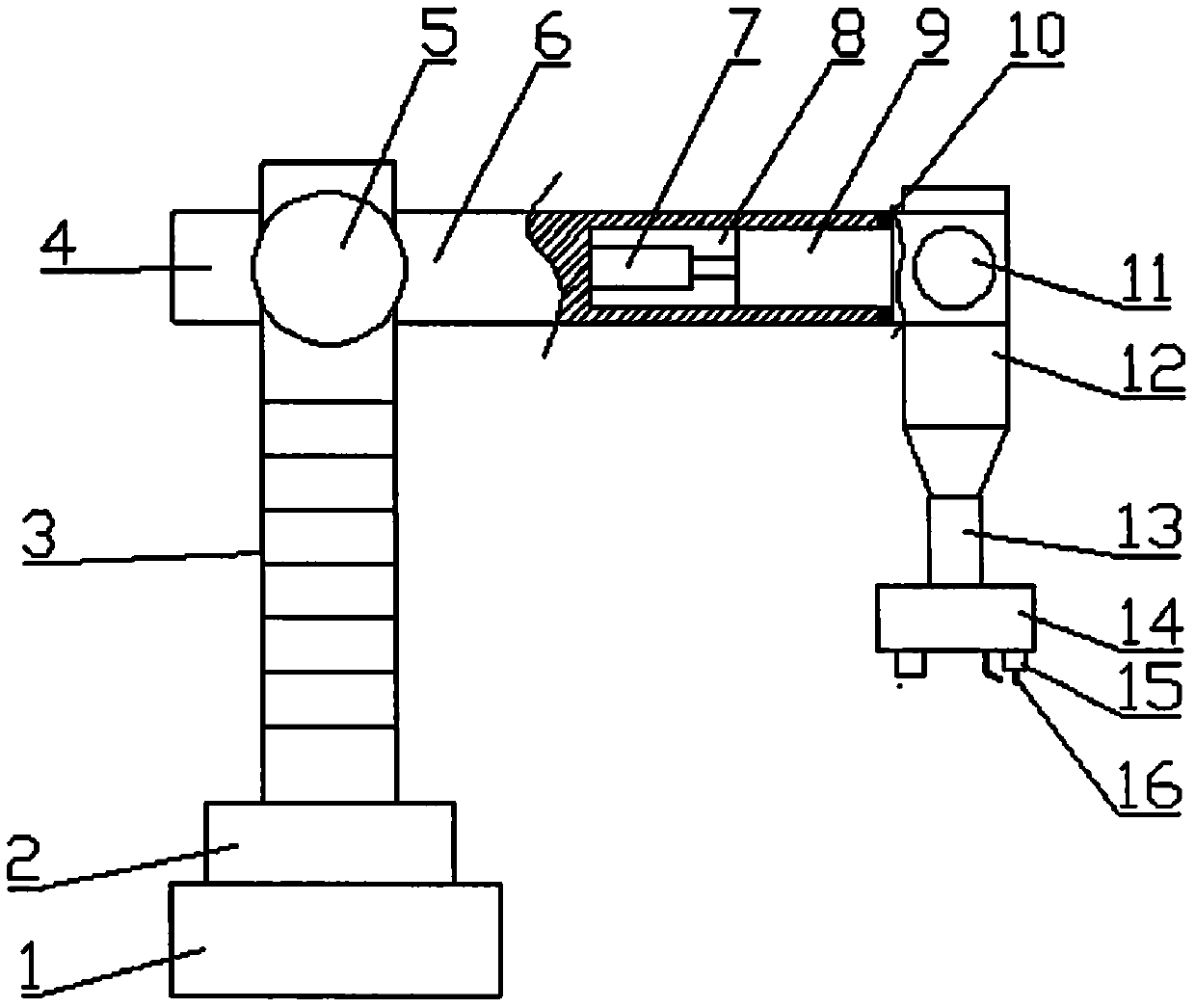

[0025] see figure 1 , in Embodiment 1 of the present invention, a multi-functional automobile whole line installation robot includes a mounting table 1, the mounting table 1 is used to install the device, the upper end of the mounting table 1 is provided with a rotating disc 2, and the rotating The disk 2 is driven by a fifth motor, and the upper end of the rotating disk 2 is fixed with a first mechanical arm 3, and the first mechanical arm 3 is connected with the second mechanical arm 6 through the first rotary joint 5, and the second mechanical arm 6 is provided with a first motor 4, which is convenient to drive the second mechanical arm 6 to rotate along the first rotary joint 5. The second mechanical arm 6 is provided with a sliding cavity 8 inside, and the sliding cavity 8 is A hydraulic cylinder 7 for driving the slide arm 9 is provided.

[0026] The sliding arm 9 is provided with a shock-absorbing pad 10, and the shock-absorbing pad 10 is arranged on the right end face...

Embodiment 2

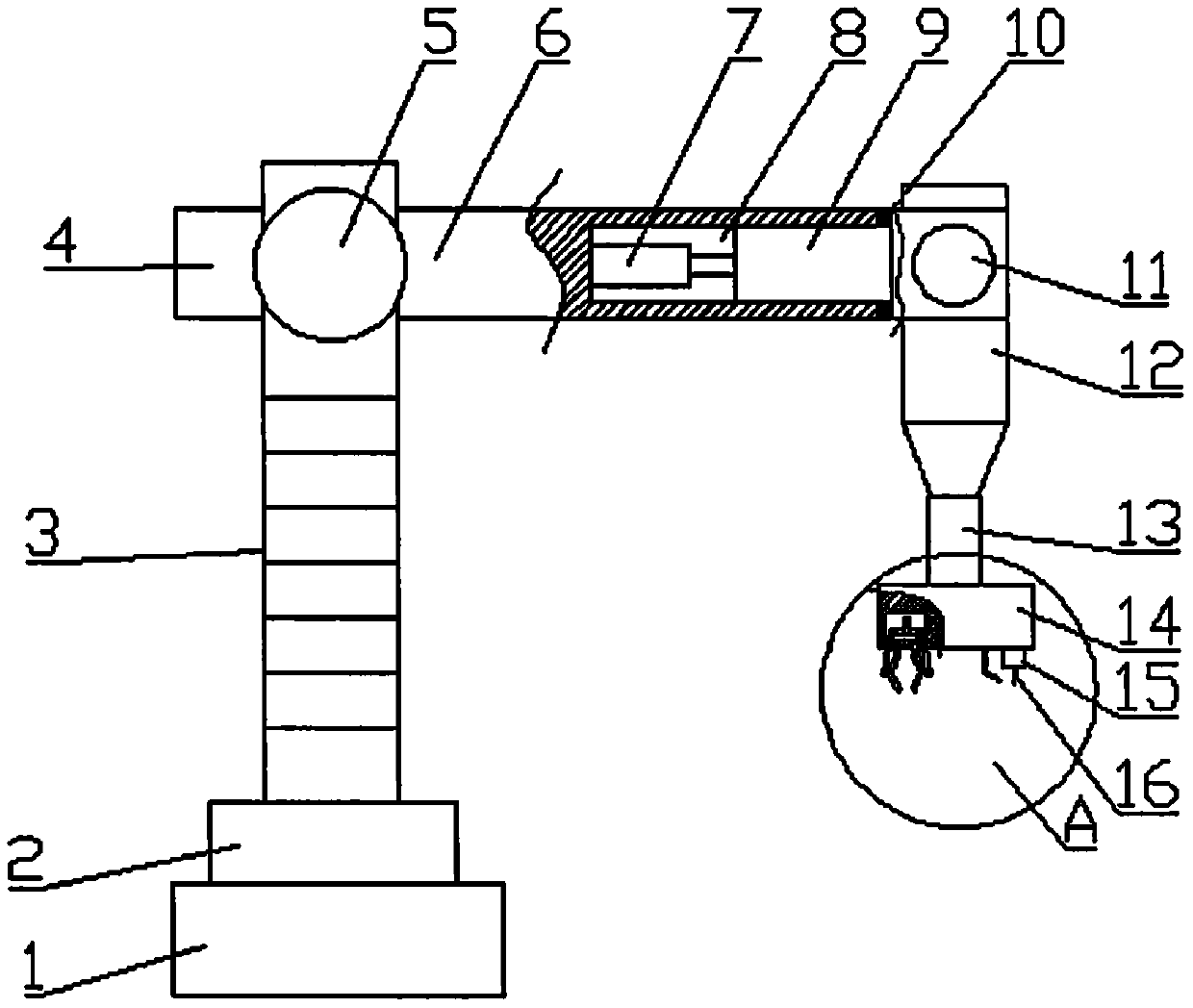

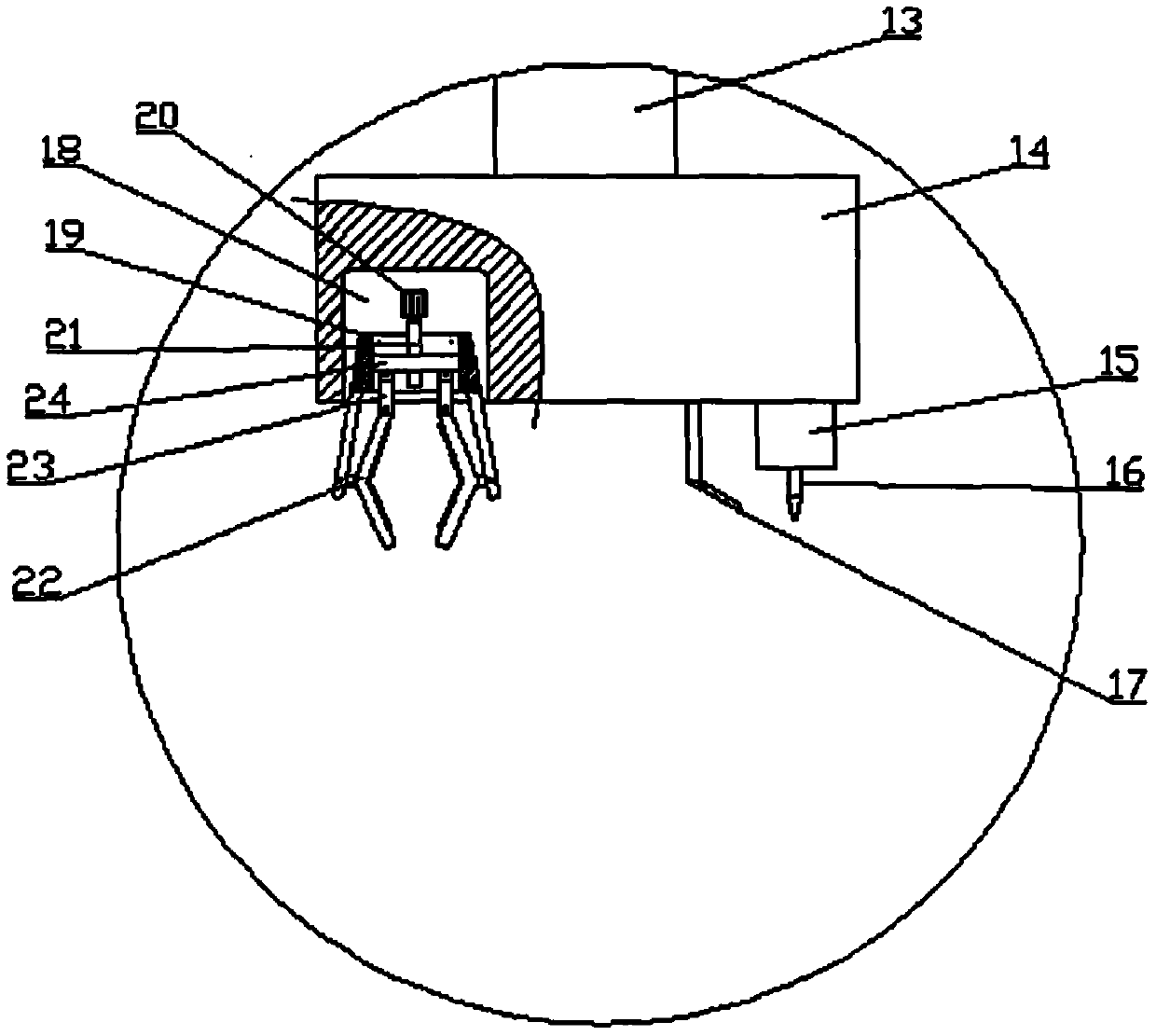

[0030] see Figure 2~4 The main difference between this embodiment 2 and embodiment 1 is that the manipulator device is arranged inside the mounting groove 18 on the working disk 14, the manipulator device includes a mounting block 19, and a chute is provided inside the mounting block 19, so The inside of the chute is slidably provided with a slider 24, the slider 24 is provided with a rotating rod 21 that drives its motion, and the rotating rod 21 is provided with an external thread that matches the threaded hole on the slider 24. The rotating rod 21 is arranged at the output end of the fourth motor 20, two connecting rods 23 are hingedly arranged on the slider 24, and the other end of the connecting rods 23 is hingedly provided with a jaw 22, and the middle part of the jaw 22 is outward Arching is convenient for picking up objects, and the middle part of the jaws 22 is hinged on the pole on the mounting block 19 through a second connecting rod. The inner side of the jaws 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com