Synthetic leather punching device and punching process

A punching device and synthetic leather technology, which is applied in metal processing and other fields, can solve the problems of synthetic leather such as easy water seepage, large pore size, and poor air permeability of synthetic leather, and achieve good waterproof effect and breathable effect, and the effect of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

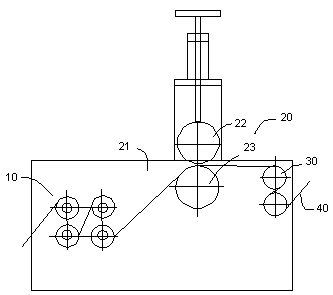

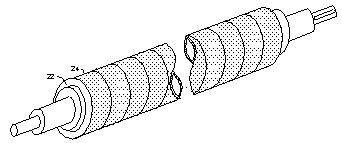

[0025] Such as Figure 1-2 The synthetic leather perforating device shown includes a first tension roller assembly 10, a needle assembly 20 and a second tension roller assembly 30 arranged in sequence; the needle assembly 20 includes a first bracket 21, a heating roller 22 and a cooling Roller 23; the heating roller 22 is pivotally connected to the first bracket 21, and a plurality of pricking needles 24 are fixed; the cooling roller 23 is pivotally connected to the first bracket 21, and the cooling roller 23 and the heating roller 22 are formed for synthesis The processing channel through which the leather 40 passes; it should be noted here that both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com