A kind of preparation method of light-weight sandwich structure long row cover for rocket

A sandwich structure and long-row cover technology, applied in the field of non-metallic materials, can solve the problems of foam core material dependence on imports, late application, and overall performance gap, etc., and achieve the effects of improving structural rigidity, increasing manufacturing costs, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

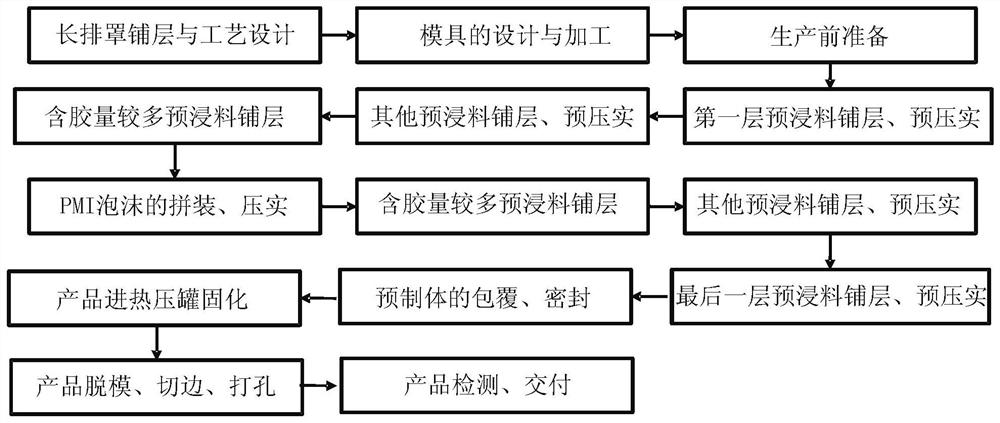

Method used

Image

Examples

example 1

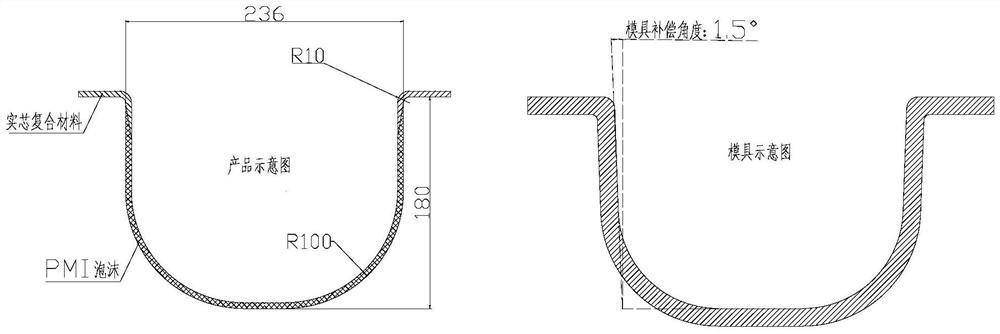

[0037] A method for manufacturing long-row hoods made of carbon-glass hybrid fabric sandwich composite materials. The long-row hoods involved in the method have a section width of 236mm, a height of 180mm, and a length of 1292mm. Thickness 4mm; The method comprises the following steps:

[0038] (1) The mold for long rows of hoods is processed and designed according to the product resistance deformation formula, and the angle between the high outward opening and its theoretical position is 1.5 degrees.

[0039] (2) After the mold is in place, carry out surface treatment and prepare corresponding MT300-3K carbon cloth / 603, SW280F / 603 prepreg and density of 110kg / m 3 PMI foam;

[0040](3) Brush epoxy 603 primer on the surface of PMI foam, and let it cool for not less than 0.5h;

[0041] (4) Lay the first layer of outer skin T300-3K / 603 on the mold, vacuum and compact it at room temperature, and then lay the second layer of outer skin SW280 / 603 prepreg;

[0042] (5) Install the...

example 2

[0048] A method for making long-row hoods made of T700 / 603A sandwich composite materials, the cross-section of the long-row hoods to be made involved in the method is 240mm wide, 128mm high, 1003mm long, 100mm high and wide side chamfers, and the thickness of the PMI foam in the middle sandwich core 4mm; the method includes the following steps:

[0049] (1) The lay-up plan of the long-row hood is {outer skin D (±45° / 90° / 0°)-PMI foam core material (thickness 4㎜)-reinforced area D (±45 / 90° / 0° ) 6 - inner skin D (0° / 90° / ±45°)}. Among them, D is T700 / 603A carbon fiber unidirectional tape prepreg;

[0050] (2) The mold for the long row of hoods is processed and designed according to the product resistance deformation formula, and the angle between the high outward opening and its theoretical position is 1.5 degrees.

[0051] (3) After the mold is in place, carry out surface treatment and prepare the corresponding T700 / 603A carbon fiber unidirectional tape prepreg with a density ...

example 3

[0060] A method for manufacturing long-row hoods made of MT300 / 603 fiber and fabric sandwich composite materials. The cross-section of the long-row hoods involved in the method has a width of 236mm, a height of 180mm, and a length of 1292mm. PMI foam thickness 5mm; the method includes the following steps:

[0061] (1) The layering plan of the long row cover is {outer skin (MT300 / 603 carbon cloth) / D(90° / 0°)-PMI foam core material (thickness 5㎜)-reinforcement area (MT300 / 603 carbon cloth) 12 -Inner skin D(0° / 90°) / (MT300 / 603 carbon cloth)}; where, D is MT300 / 603 carbon fiber unidirectional tape prepreg;

[0062] (2) The mold for the long row of hoods is processed and designed according to the product resistance deformation formula, and the angle between the high outward opening and its theoretical position is 1.5 degrees.

[0063] (3) After the mold is in place, carry out surface treatment and prepare corresponding MT300-3K carbon cloth / 603, MT300 / 603 unidirectional prepreg with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com