A Highly Reliable Method for Stroke Positioning of Bucket Wheel Machine

A technology of travel positioning and bucket wheel machine, which is applied in the management of digital coal yards and the field of bucket wheel machine travel positioning, which can solve the problems of measurement being susceptible to electromagnetic interference and loss of measurement data, and achieve the effects of easy implementation, elimination of influence, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

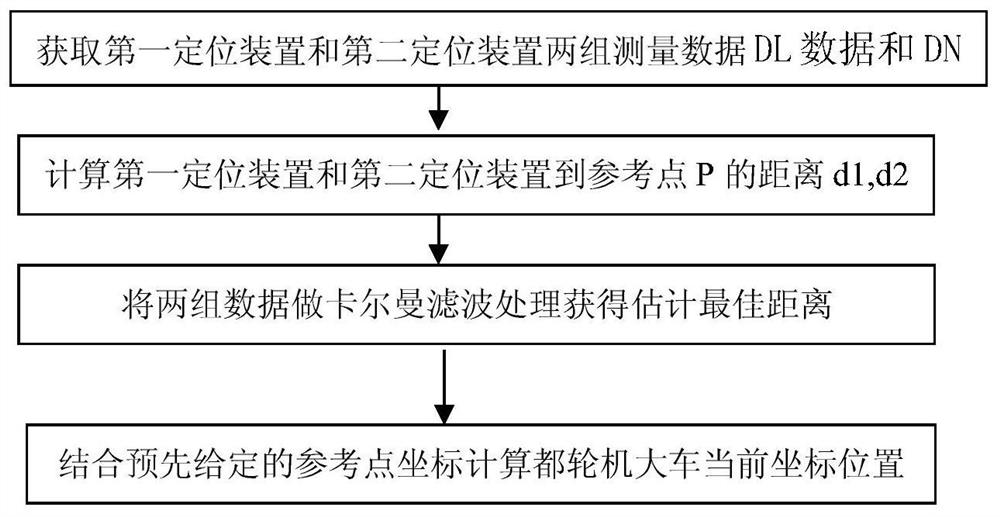

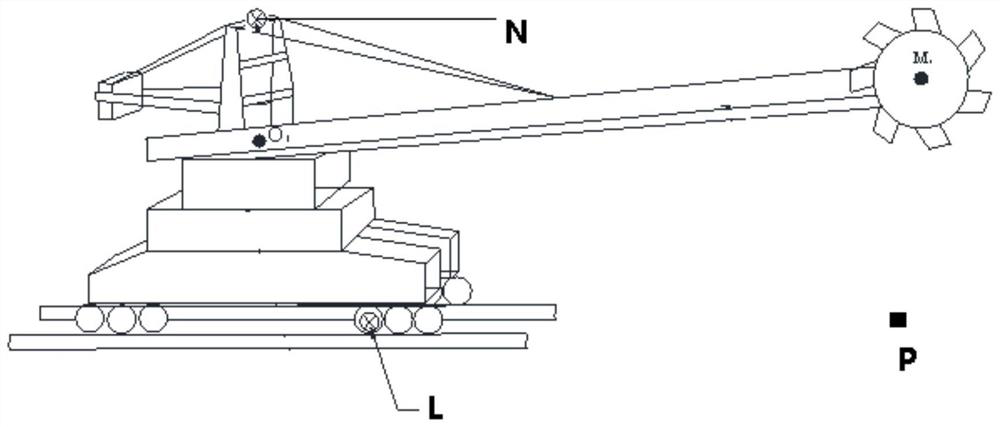

[0041] Such as figure 1 As shown, a highly reliable bucket stroke positioning method of the present invention is installed on a bucket (first positioning device and the second positioning device) on the bucket, and its steps are:

[0042] S1: Get two sets of measurement data DL data and DN data for the first positioning device and the second positioning device;

[0043] S2: Calculate the first positioning device and the second positioning device to the distance D1, D2 of the reference point P;

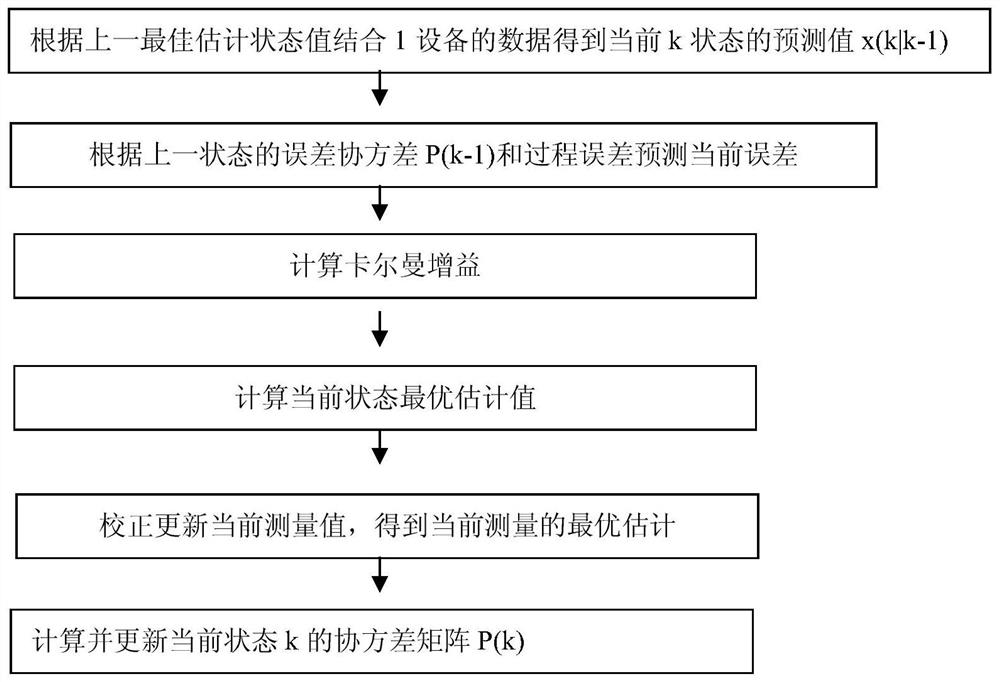

[0044] S3: Galman filtering processing for two sets of data is given the best distance;

[0045] S4: Combined with a predetermined reference point coordinate calculation of the current coordinate position of the big wheel.

[0046] In the above step S1, the two sets of measurement data A data of the first positioning device and the second positioning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com