Air spring lifter and using method thereof

An air spring and rubber air spring technology, applied in the field of lifting, can solve the problems of poor adjustment of the lifting height, wear and leakage failure, complex system, etc., and achieve the effect of simple structure, reliable operation, and solving the complex system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

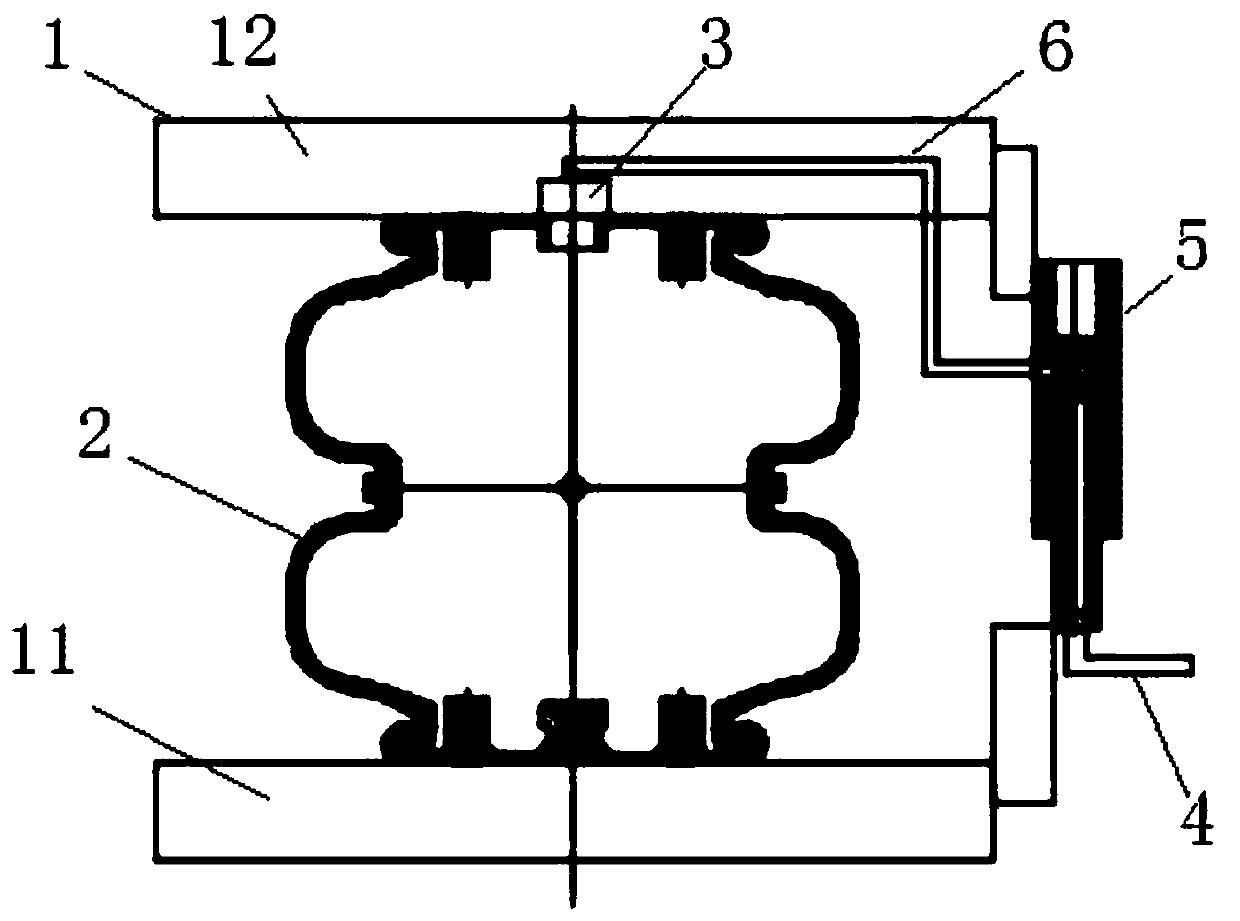

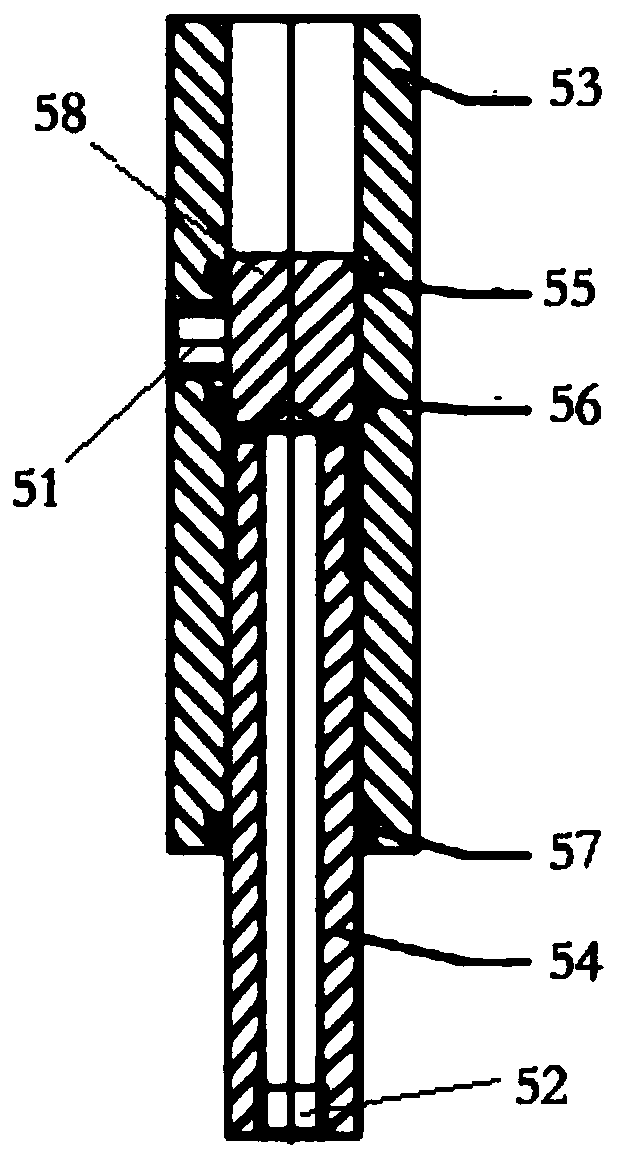

[0013] Refer to attached figure 1 , the present embodiment provides an air spring lifter, including a lifter frame 1, a rubber air spring 2 and a height adjustment valve 5, the lifter frame 1 includes a bottom plate 11 and a top plate 12 arranged in parallel above the bottom plate 11 , the rubber air spring 2 is arranged between the bottom plate 11 and the top plate 12, and the upper and lower ends of the rubber air spring 2 are respectively fixed on the top plate 12 and the bottom plate 11 of the lift frame 1, and the upper and lower ends of the height adjustment valve 5 are respectively Fixed on the top plate 12 and the bottom plate 11, the upper end of the rubber air spring 2 is connected to the air intake nozzle 3, and the air intake nozzle 3 is connected to the air spring intake and exhaust port 51 on the height adjustment valve 5 through the air circulation pipe 6, and the height adjustment valve 5 The compressed air interface 52 is connected to the compressed air source...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap