Device for realizing zero emission of desulfurization wastewater and coupled cooperative control of white smoke plume

A desulfurization wastewater, collaborative control technology, applied in gaseous discharge wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of repeated investment in projects, high operating costs, and achieve a simple process flow Reliable, low operating costs, temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

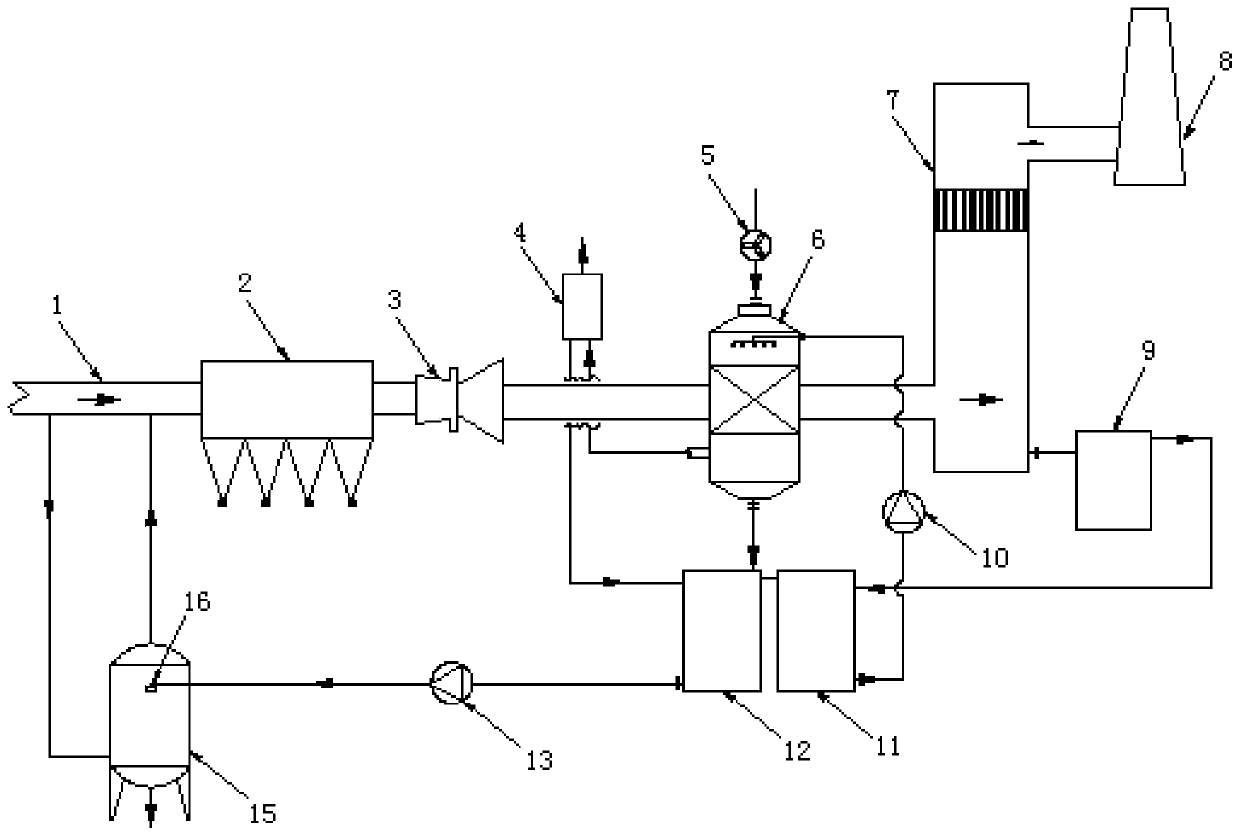

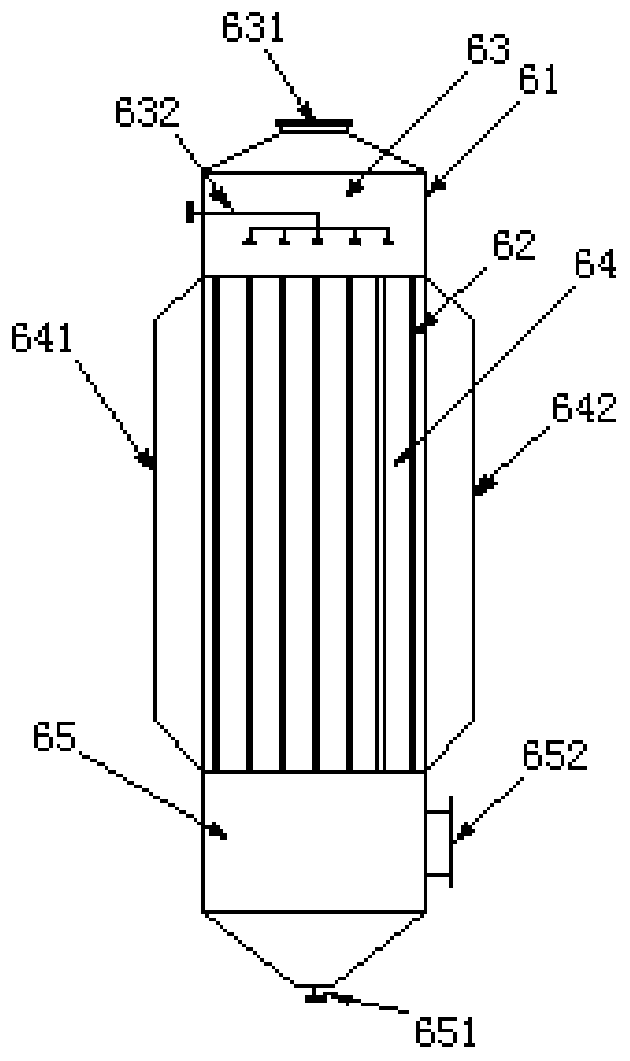

[0037] Such as figure 1 As shown, the schematic diagram of the device structure for realizing zero discharge of desulfurization wastewater and coupling and cooperatively controlling white plume provided by this embodiment, including the flue 1 at the entrance of the desulfurization tower 7 in a direction from far to near the entrance of the desulfurization tower 7 The flue 1 is connected with the dust collector 2, the induced draft fan 3 and the gas-liquid phase change coupling heat exchanger 6, the desulfurization waste water outlet of the desulfurization tower 7 is connected to the sedimentation tank 9, the outlet of the sedimentation tank 9 is connected to the clean water tank 11, the clean water tank 11 The outlet is connected to the liquid inlet of the gas-liquid phase variable heat exchanger 6 through a pipeline, a circulating pump 10 is arranged on the pipeline, and the liquid outlet of the gas-liquid phase variable heat exchanger 6 is connected to the concentrated liquid ...

Embodiment 2

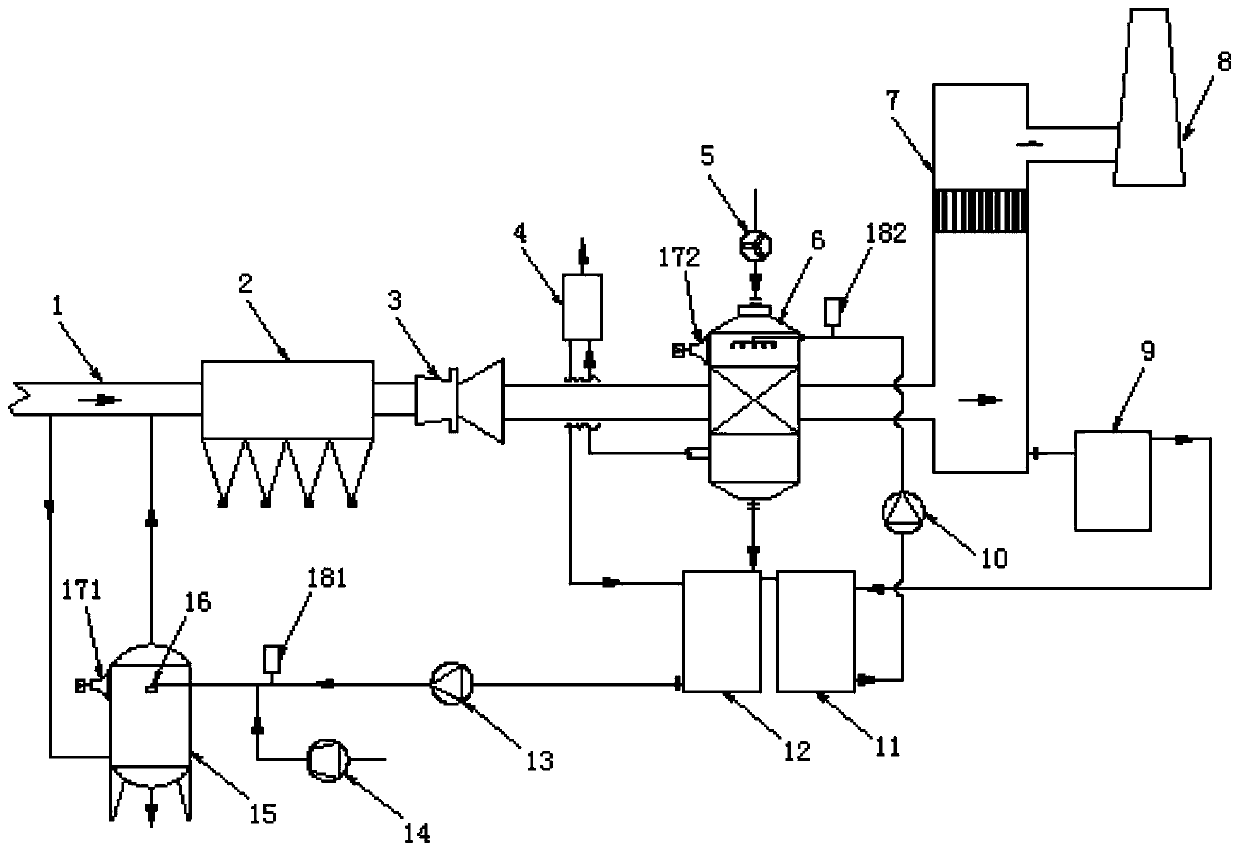

[0040] This embodiment is a further improvement on the basis of embodiment 1, such as image 3 As shown, a first sonic soot blower 171 is provided on the flash tank 15, and a second sonic soot blower 172 is provided on the gas-liquid phase change coupling heat exchanger 6, which passes through the first sonic soot blower 171 The second sonic soot blower 172 performs sonic soot blowing on the solid deposition layer deposited on the inner wall of the flash tank 15 and the gas-liquid phase change coupled heat exchanger 6 to maintain the effective operation of the entire system.

[0041] The pipeline connecting the concentrated liquid tank 12 and the flash tank 15 is provided with a first sonic descaling device 181, and the pipeline connecting the clean water tank 11 and the gas-liquid phase variable coupling heat exchanger 6 is provided with a second sonic descaling device 182, The first sonic descaling device 181 and the second sonic descaling device 182 can effectively remove the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com