FRP high-efficiency counterflow cooling tower

A counter-flow, glass fiber reinforced plastic technology, applied in the field of cooling tower equipment, can solve the problems of high manufacturing cost, slowing down industrial production rhythm, complex cooling tower structure, etc., to improve the cooling performance, expand the cooling effect, and increase the effect of residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

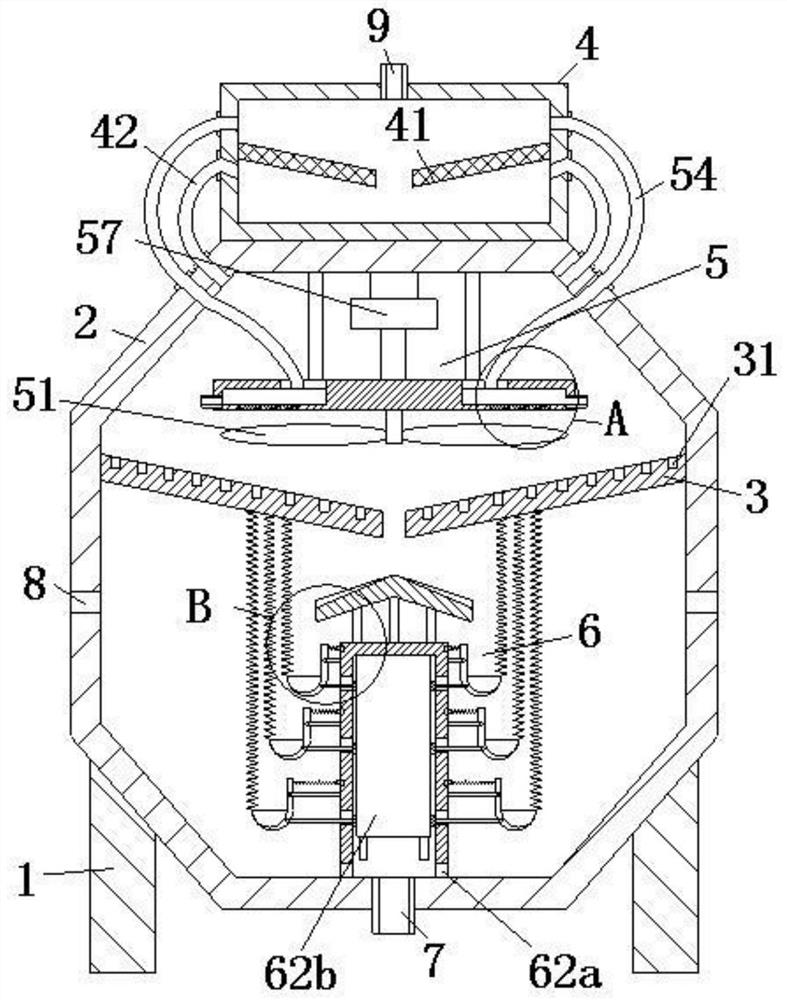

[0024] use Figure 1-Figure 5A high-efficiency counterflow cooling tower made of glass fiber reinforced plastics according to one embodiment of the present invention will be described below.

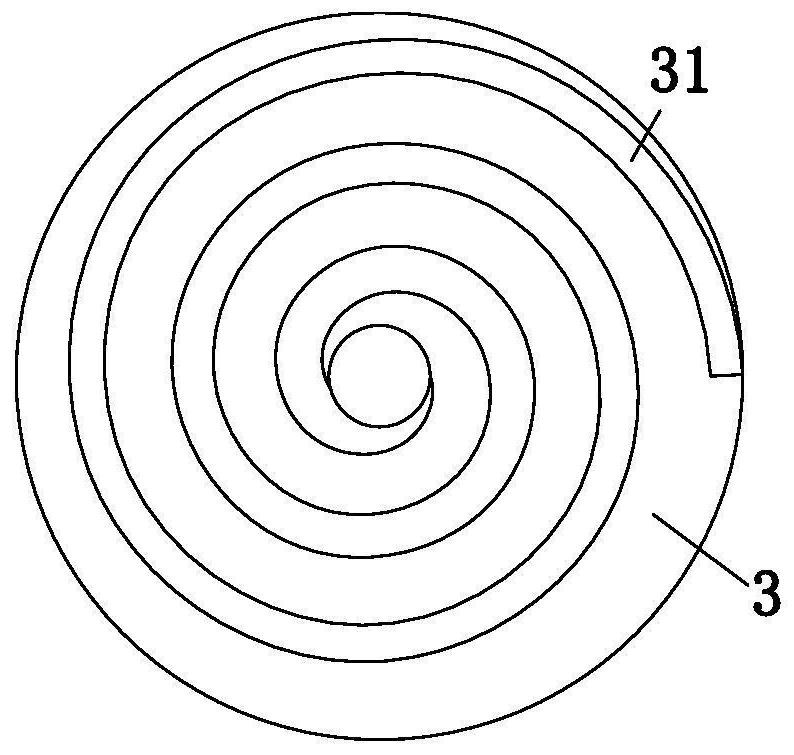

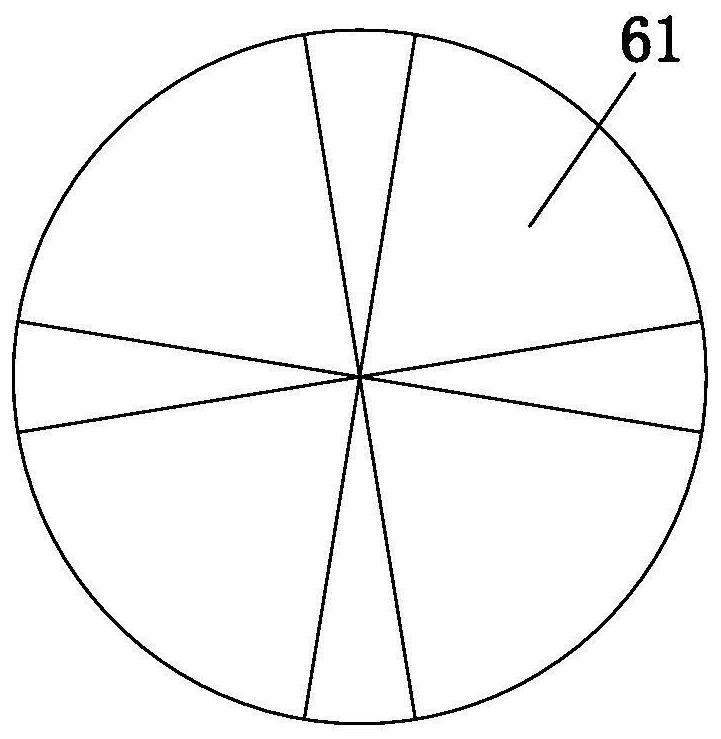

[0025] Such as Figure 1-Figure 5 As shown, the high-efficiency counterflow cooling tower made of glass fiber reinforced plastics of the present invention includes a base 1, a frame body 2, a flow plate 3, a pre-storage tank 4, a spraying mechanism 5, a split cooling mechanism 6 and a water outlet pipe 7; the base 1 is provided with four, and the base 1 is evenly and fixedly installed on the lower surface around the frame body 2; the outer surface of the upper end of the frame body 2 is fixedly installed with a pre-storage water tank 4, and the middle wall of the frame body 2 is uniformly provided with air holes 8, and the frame body 2. The upper end of the interior is provided with a spraying mechanism 5; the upper end wall of the pre-storage tank 4 is fixedly connected with a water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com