Test device capable of cementing rock joint surfaces through using fluid in phased manner and use method

A technology of rock joints and test equipment, which is applied in the field of rock joint surface research, can solve the problems of shear deformation abstraction, inability to form intuitive exploration, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

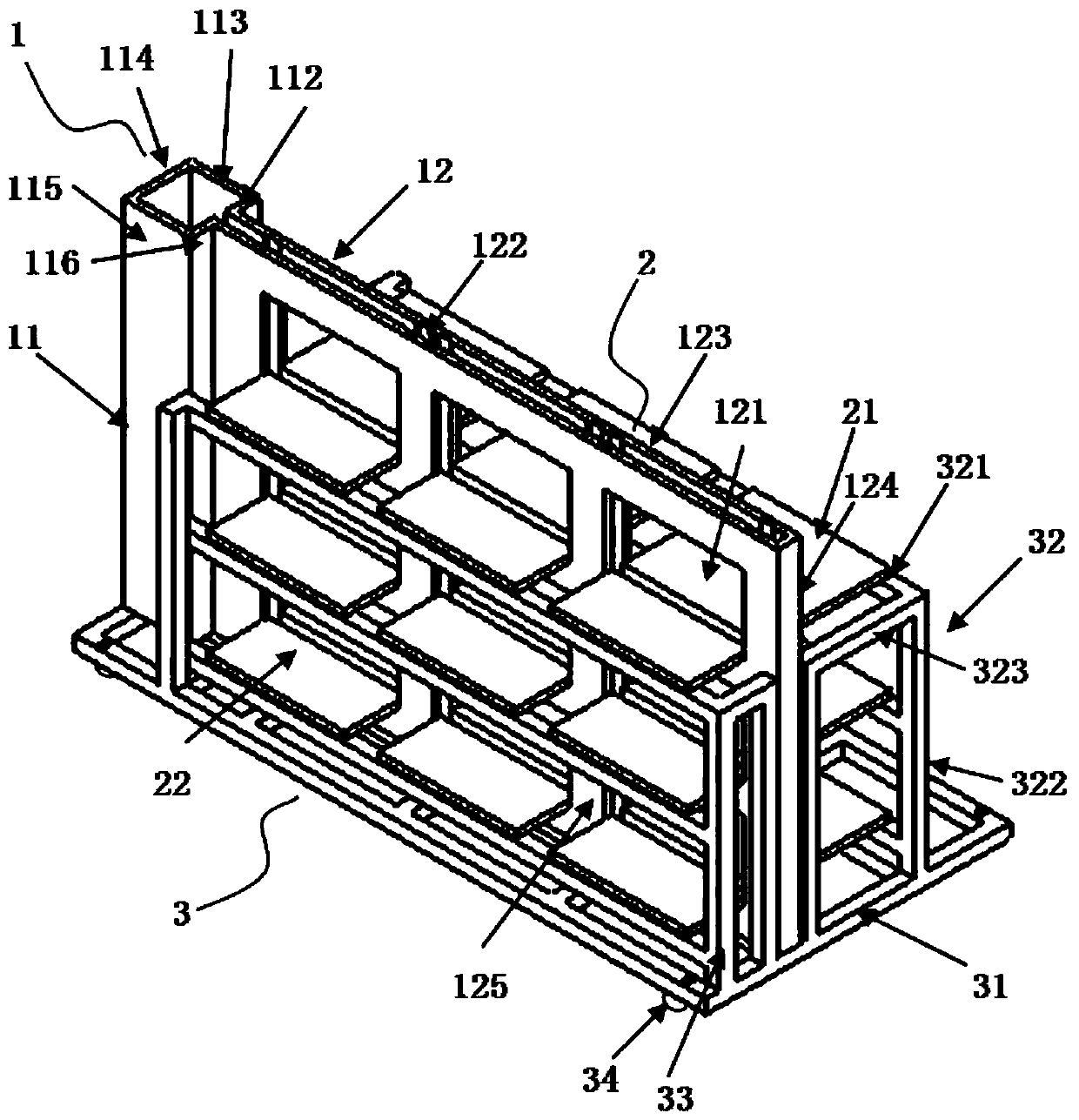

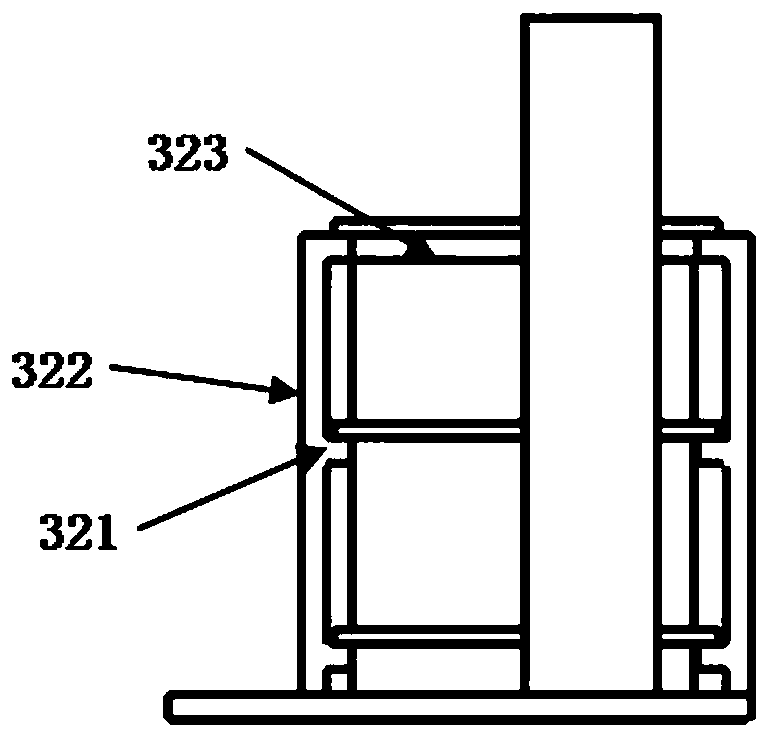

[0051] The test device provided by the present invention can use fluid to cement the rock joint surface in stages, such as Figure 1 to Figure 4 As shown, it includes a slurry injection member 1, several blocking members, several platform assemblies 2 for placing specimens for simulating the cementation of rock joint surfaces, and a support body 3 for supporting and fixing the slurry injection member and the platform assembly.

[0052] like figure 1 and figure 2 As shown, the slurry injection member 1 includes a first injection box 11 and a second injection box 12 that communicate with each other. The cross section of the first injection box 11 is square, and the side plate of the first injection box is formed by connecting the first side plate 112, the second side plate 113, the third side plate 114, the fourth side plate 115, and the fifth side plate 116 in sequence. The second injection box 12 is of a rectangular parallelepiped structure, and the side plate of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com