Permeability enhancement and lixiviation test system for low-permeability uranium-bearing sandstone

A test system and low-permeability technology, which is applied in the field of low-permeability uranium-containing sandstone permeation-increasing leaching test system, can solve the problems of high mining cost, low leaching rate, and small pumping liquid volume, so as to accelerate the uranium leaching rate and increase Uranium leaching rate, effect of intensifying liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

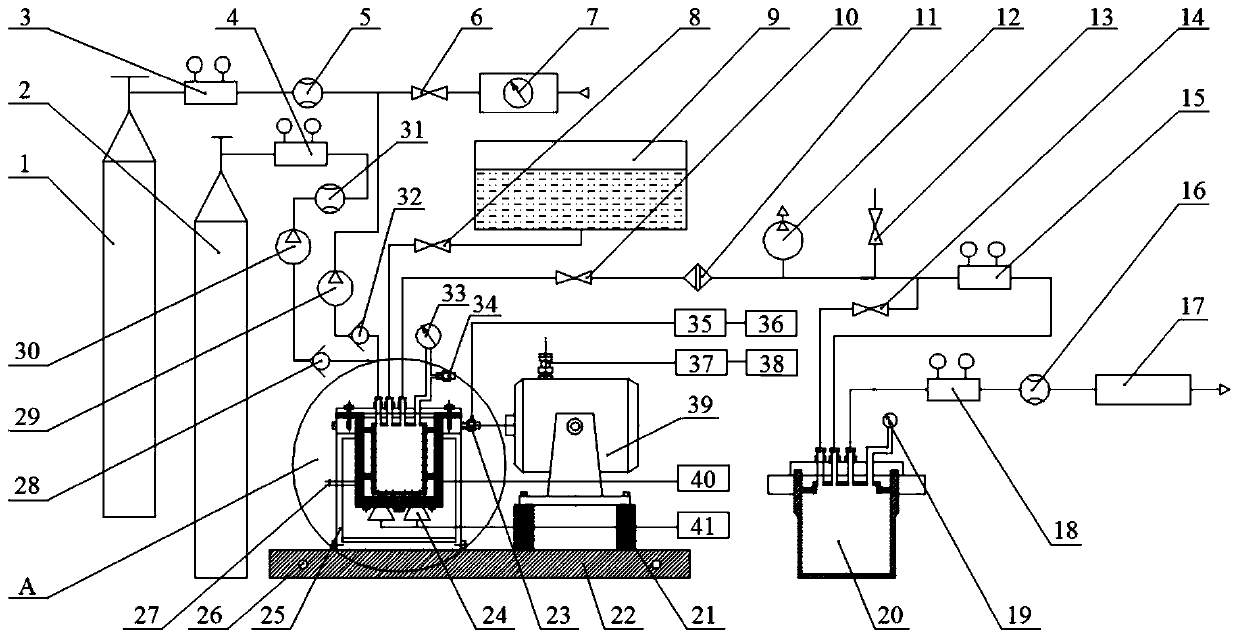

[0030] Attached below Figure 1 to Figure 7 , a specific embodiment of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

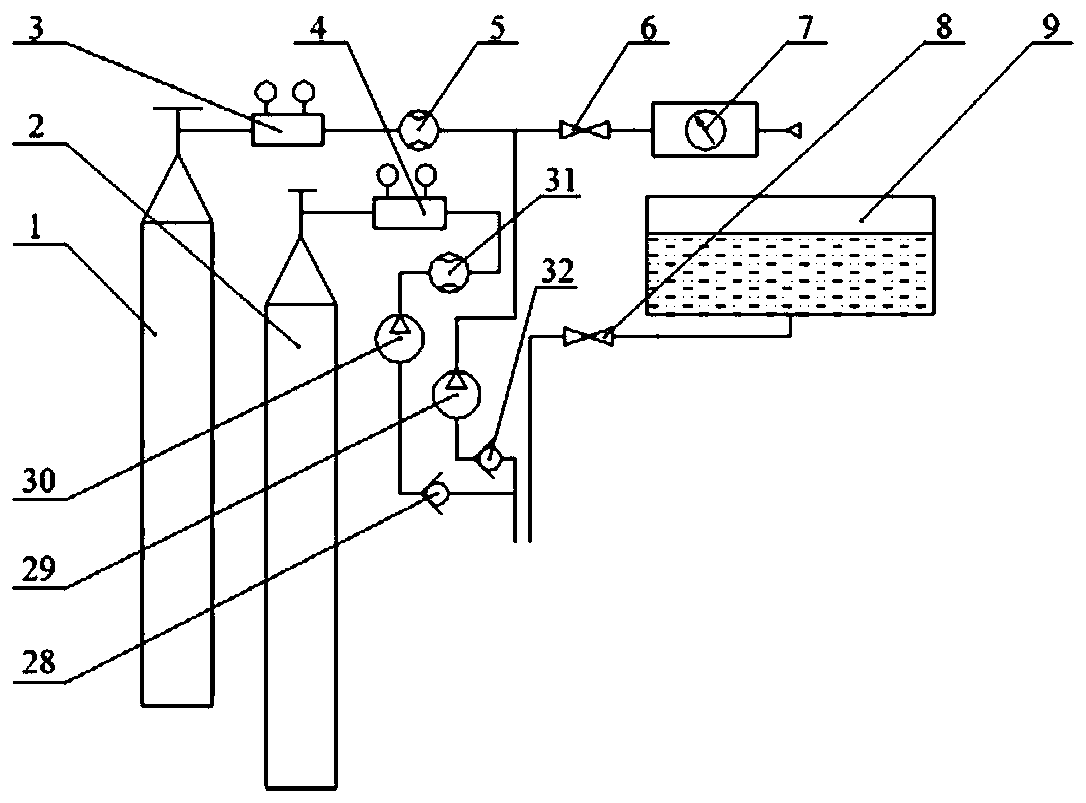

[0031] Such as figure 1 As shown, a leaching test system for low-permeability uranium-containing sandstone includes a reaction device, and the reaction device is respectively equipped with a heating device for heating the sample, and is used to supply water, oxygen, and carbon dioxide to the inside of the reaction device. A water vapor supply system for gas and air, a high-low frequency excitation system for applying high-frequency vibration and low-frequency vibration required for the test to the reaction device, and a data acquisition system for collecting experimental data.

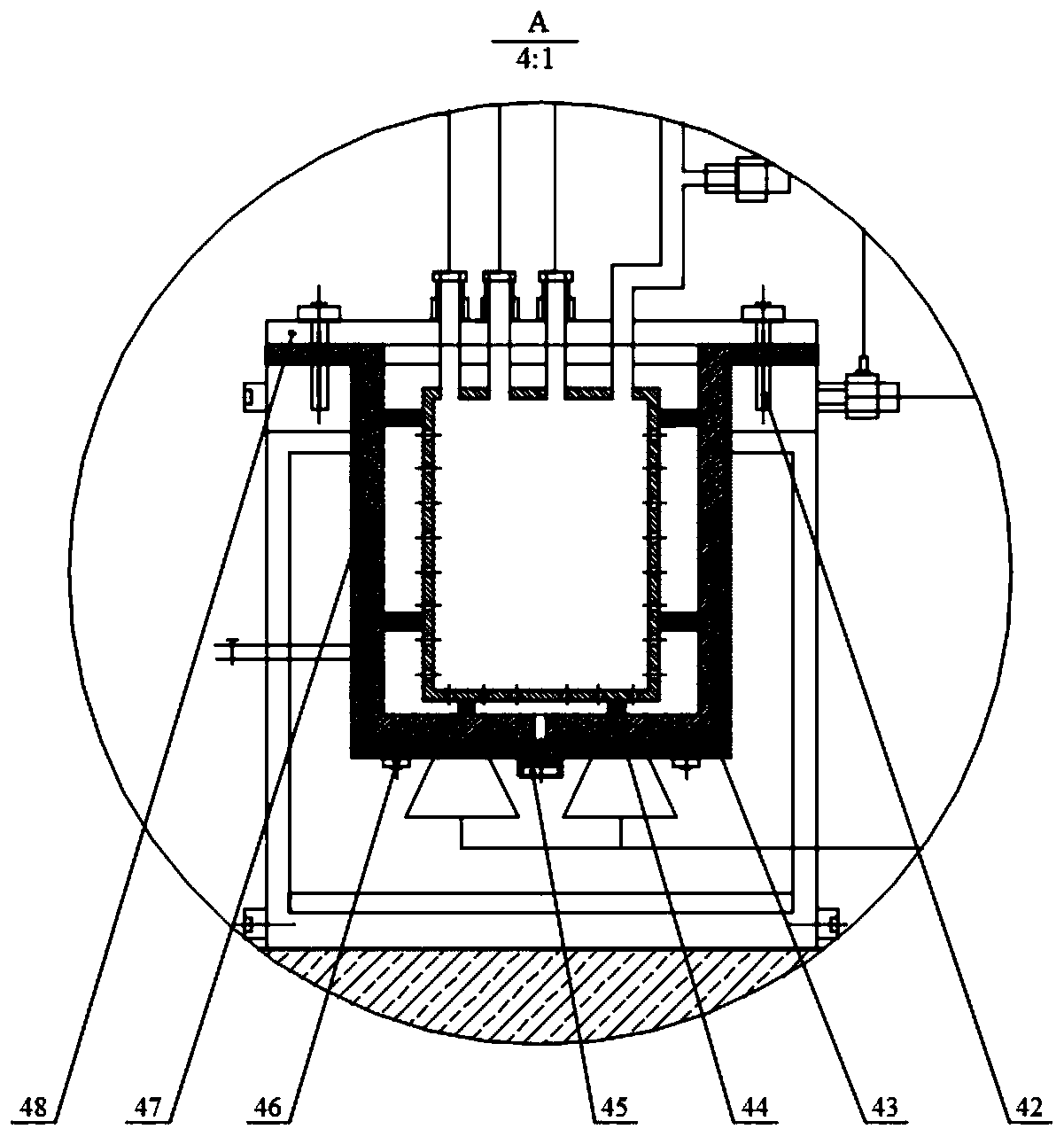

[0032] Further, such as figure 2 As shown, the reaction device includes a reaction tank 44 for containing samples, and the top of the reaction tank 44 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com