Novel high-integration multi-core ribbon optical cable

A ribbon-shaped optical cable, highly integrated technology, applied in the direction of fiber mechanical structure, etc., can solve the problems that cannot meet the requirements of optical cable flexibility, small outer diameter and high density, large bandwidth, environmental protection and energy saving, complicated cable production process, single technology, etc., to achieve The effect of shortening the connection time, solving the problem of cleaning and environmental protection, and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

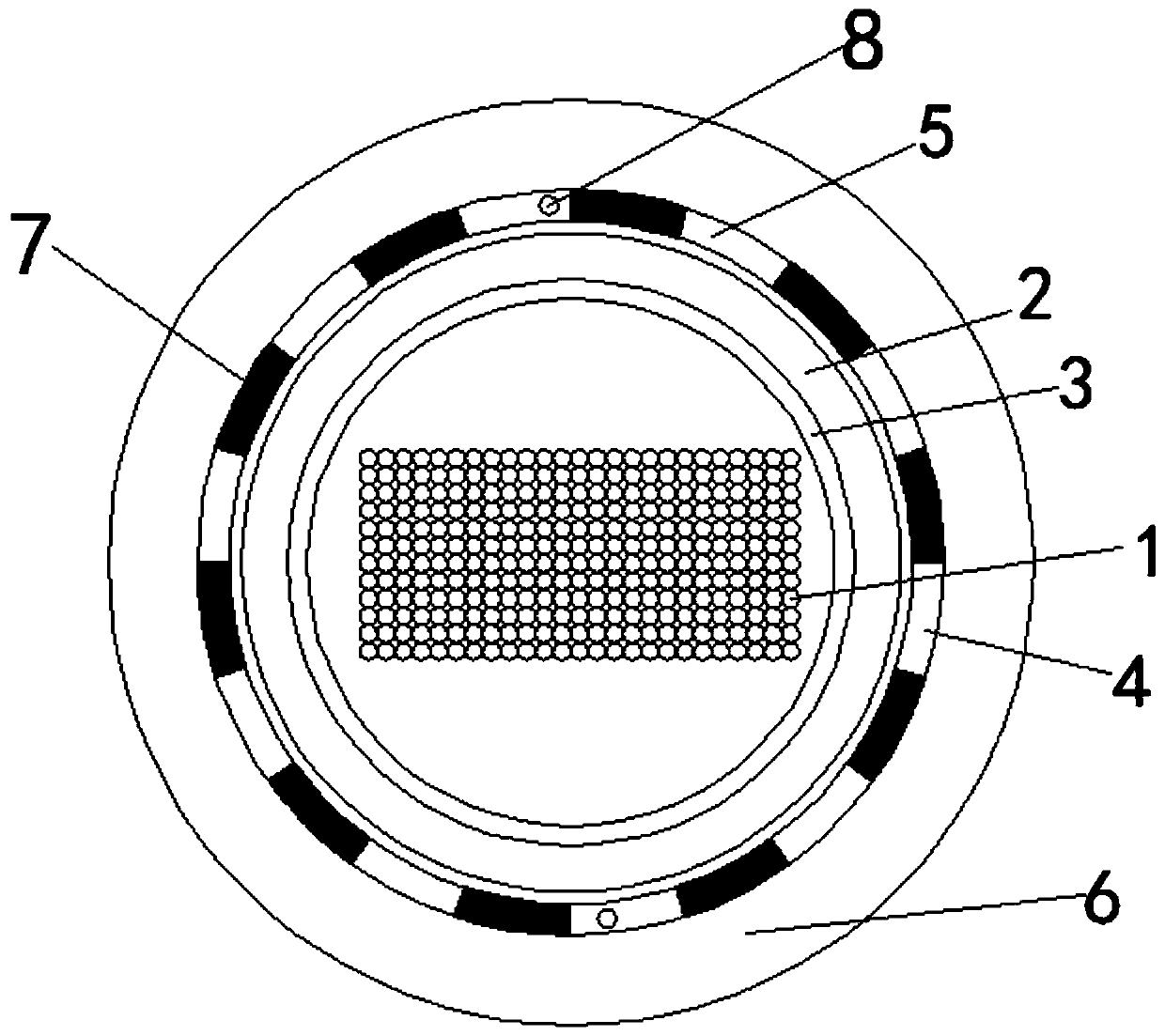

[0024] see figure 1 , according to an embodiment of the present invention, a novel high-integrated multi-core ribbon cable includes an optical fiber ribbon strand 1, the optical fiber ribbon strand 1 is wrapped with a strengthening layer 2, and the inside and outside of the strengthening layer 2 are respectively provided with water-blocking Layer 1 3 and water blocking layer 2 4 , the side of the water blocking layer 2 4 away from the reinforcement layer 2 is provided with an outer sheath 5 , and the outside of the outer sheath 5 is provided with a general sheath 6 .

[0025] Through the above solution of the present invention, the integration degree of the optical fiber in the optical cable is improved: packing density, that is to say, more optical fibers can be accommodated in the optical cable with the same outer diameter. This not only saves cable costs, but further saves duct space. The fast connection is convenient, and the application of the fiber ribbon cable makes it...

Embodiment 2

[0027] see figure 1 , for the optical fiber ribbon strand 1, the optical fiber ribbon strand 1 is formed by twisting one or more optical fiber ribbons, and each optical fiber ribbon may contain 12, 16 or 24 optical fibers. For the water blocking layer 1 3, the water blocking layer 3 and the water blocking layer 2 4 both include cavities, and the cavities are respectively opened on both sides of the reinforcing layer 2, and the cavities Filled with water blocking powder. Material saving, good waterproof performance. As for the outer sheath 5 , the non-metal reinforcing material glass yarn 7 is evenly fixed on the outer sheath 5 . In another embodiment, the non-metallic reinforcing material 7 can be replaced by aramid yarn, which increases the tensile resistance of the protective cover. For the outer sheath 5 , two tearing cords 8 are fixed inside the outer sheath 5 , and the tearing cords 8 are arranged symmetrically according to the central position of the outer sheath 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com