Coke oven raw gas sensible heat recovery device and recovery method

A technology for sensible heat recovery and waste gas, which is applied in the steam generation method using heat carrier, the heating of coke ovens, and the discharge device of dry distillation gas, etc., can solve the problems of high cost of high temperature heat pipes, blockage of waste gas channels, and high operating costs. , to achieve the effect of excellent anti-corrosion performance, saving pipeline space and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes the implementation of the present invention in detail with reference to the accompanying drawings, but they do not constitute a limitation to the present invention, and are merely examples. At the same time, the advantages of the present invention are made clearer and easier to understand through the description.

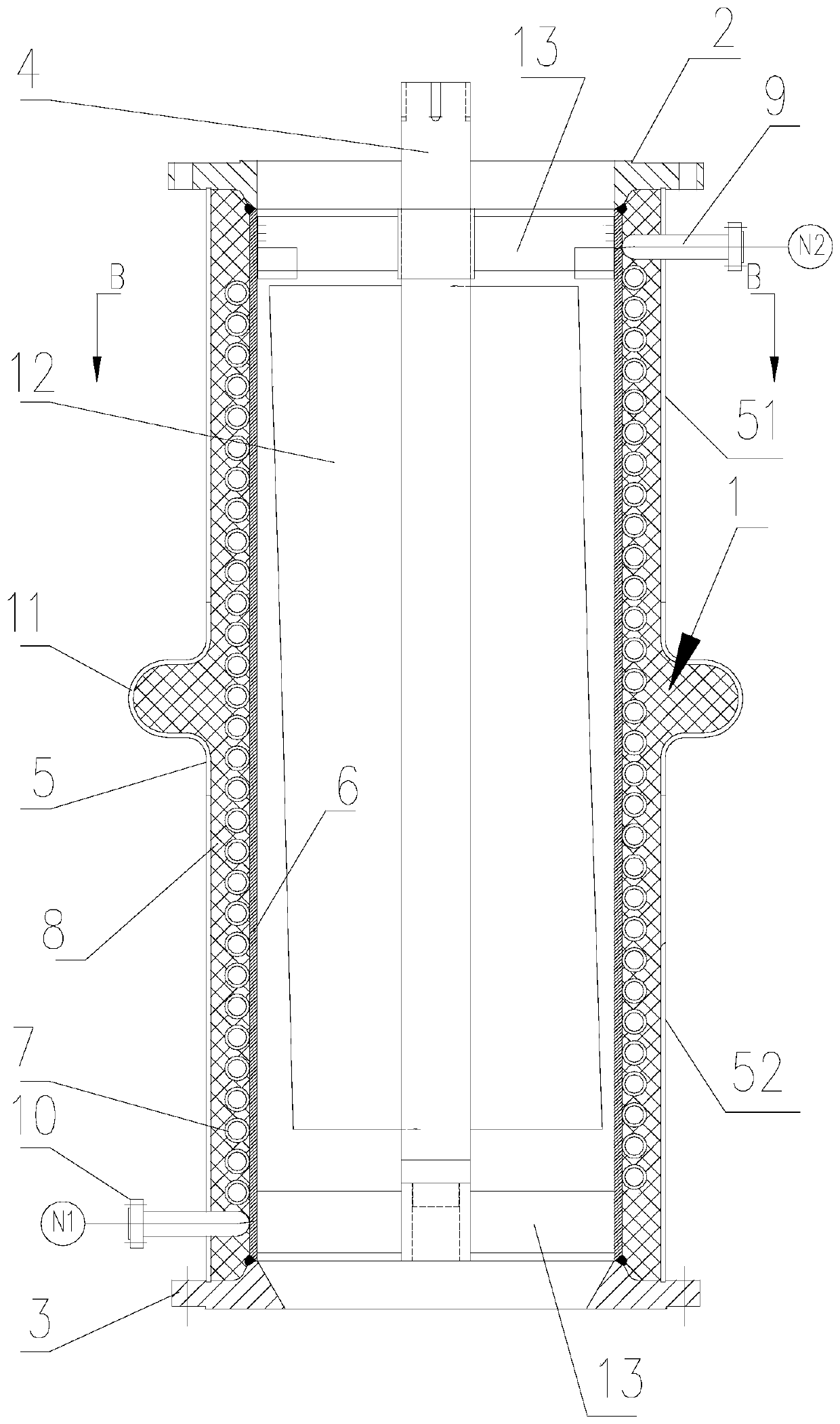

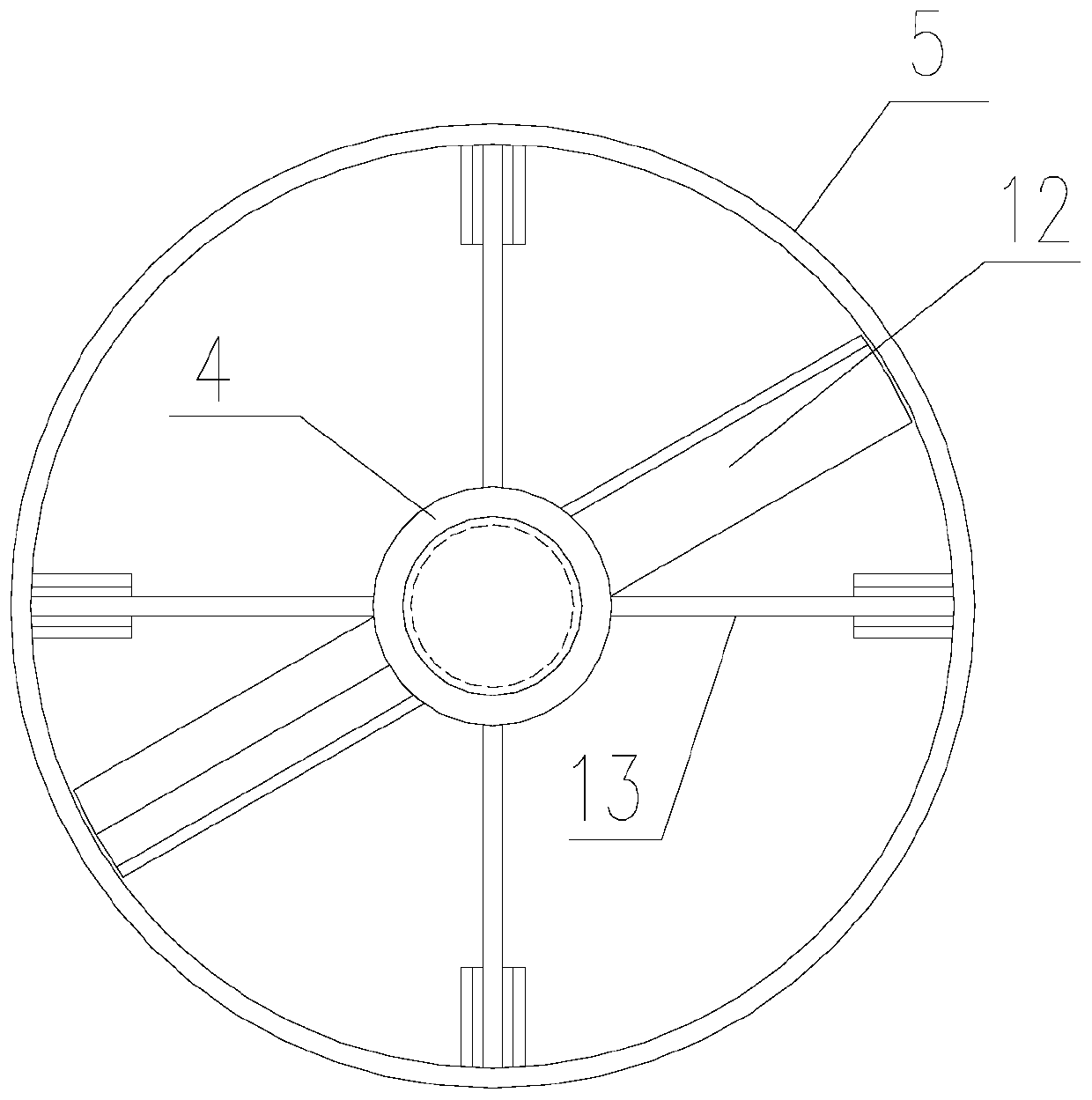

[0028] With reference to the attached drawings, it can be seen that a coke oven raw gas sensible heat recovery and utilization device includes a shell 1, an upper support 2 connected to the upper end of the shell 1, a lower support 3 connected to the lower end of the shell 1, and a The mandrel 4 in the accommodating space, the upper end of the mandrel 4 is connected to the upper end of the housing 1 or the upper support 2 through the positioning plate 13, and the lower end of the mandrel 4 is connected to the lower end or the lower support 3 of the housing 1 through the positioning plate 13 The housing 1 includes an outer cylinder 5 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com