Vending machine and mechanism to pierce and heat sealed dining bowls

A technology for serving bowls and heating components, which is applied in the direction of processing coins or valuable banknotes, instruments, etc., can solve the problems of not considering the reliability of automatic vending machines, low heating efficiency, and increasing the load of the driving mechanism, so as to improve sales. Efficiency, the effect of shortening the heating time and prolonging the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

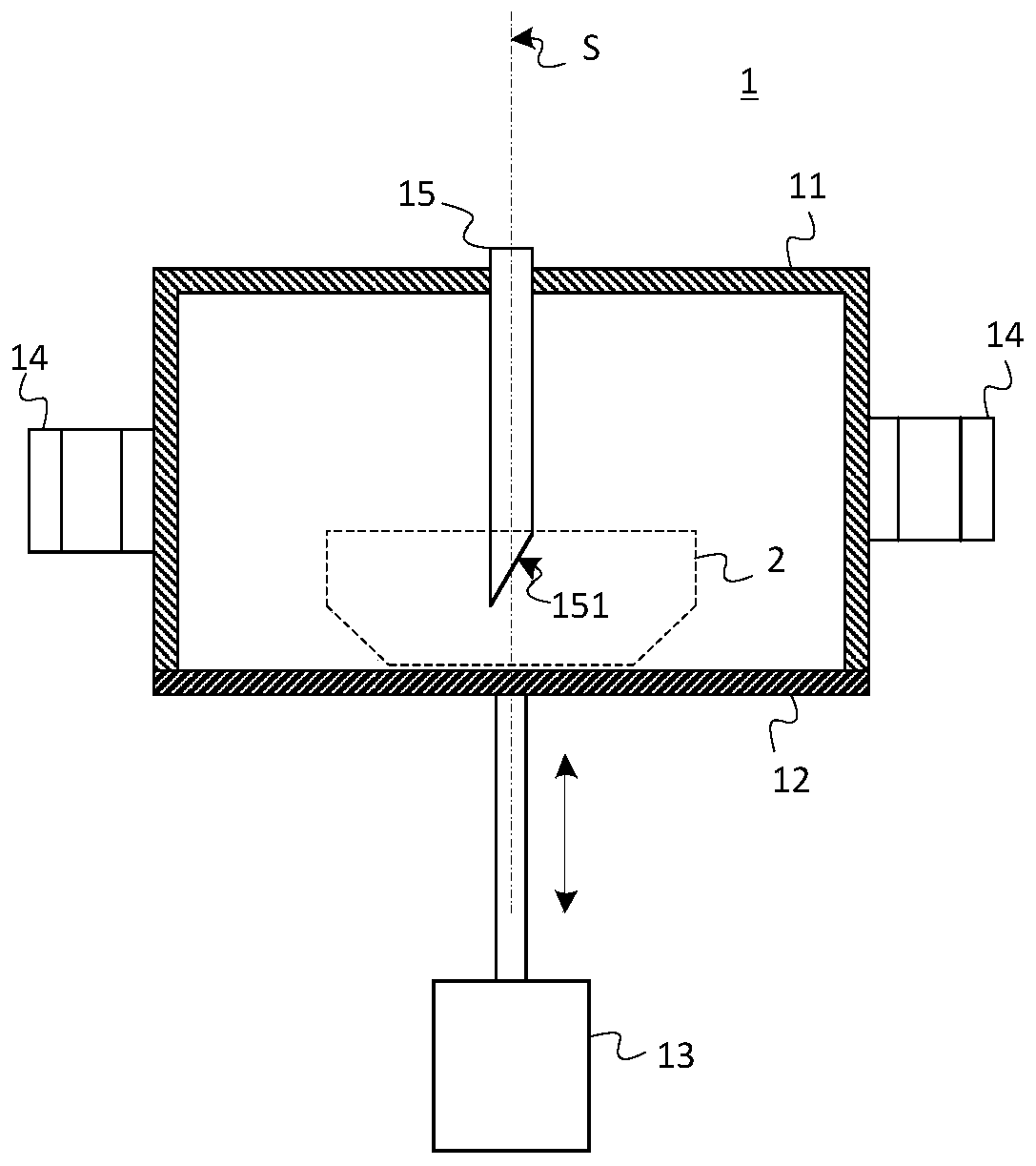

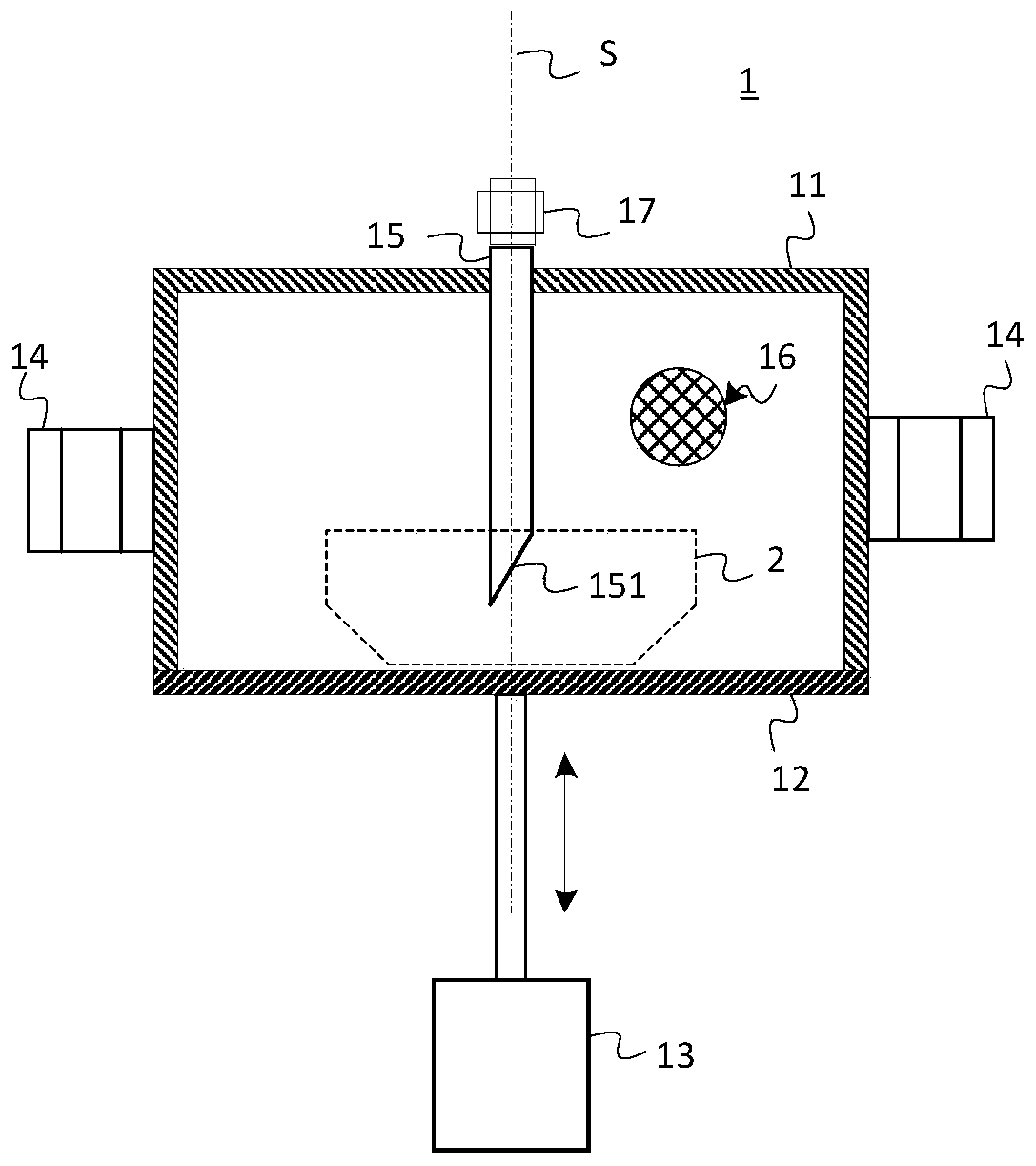

[0032] See figure 1 , provides a schematic diagram of the principle of an embodiment of a mechanism for puncturing and heating sealed bowls of the present invention, as shown in the figure, the mechanism includes a microwave cover 11, a tray 12, a lifting drive device 13, and a feeding tube 15 and a heating assembly 14, the microwave cover 11 is fixedly arranged in a vertical direction S, the tray 12 is arranged under the microwave cover 11 so as to reciprocate along the vertical direction S, and the tray 12 is connected to the The vertical direction S moves upwards and the lifting drive device 13 forming a closed space with the microwave cover 11, the heating assembly 14 is fixedly arranged on the outer surface of the microwave cover 11, the number is one or more, and the injection pipe 15 includes The first end and the second end, the first end of the injection tube 15 extends into the microwave cover 11 from the top of the microwave cover 11 and is parallel to the vertical ...

Embodiment 2

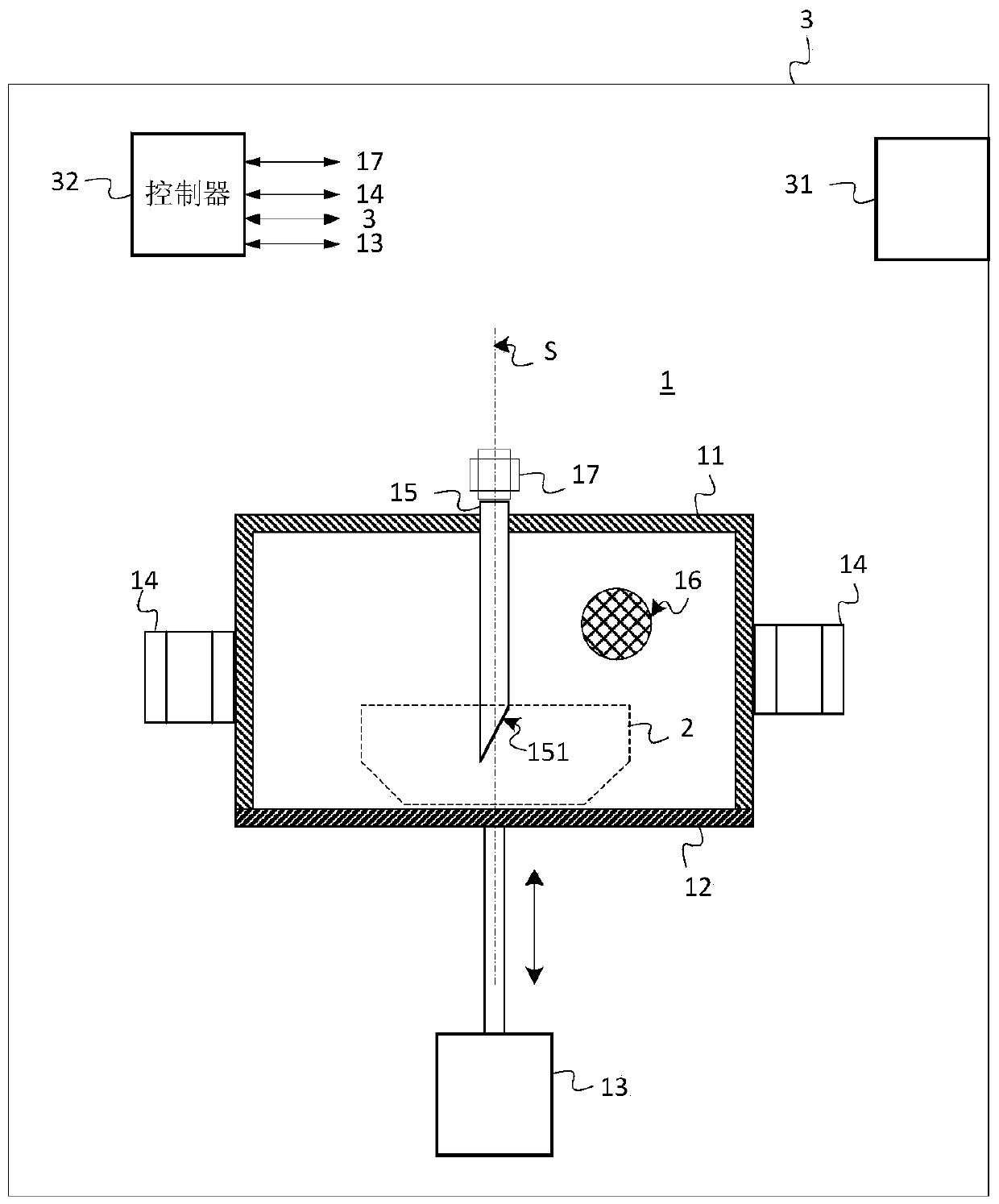

[0040] See image 3 , this embodiment provides a schematic diagram of the vending machine in an embodiment of the present invention, as shown in the figure, the vending machine 3 includes a controller 32, an exhaust device 31 and a pair of sealed meals of any implementation structure in embodiment 1 Mechanism 1 for piercing and heating the bowl.

[0041] In this embodiment, the automatic control of the mechanism in the first embodiment is realized by adding an electrical control program, so as to realize the automatic control of the heating process and improve the efficiency.

[0042]Specifically, the controller is respectively connected to the lifting control device 13, the heating assembly 14, the exhaust device 31 and the multi-way valve 17. In this embodiment, the process of the vending machine controlling the mechanism 1 through the controller is as follows:

[0043] In the first step, when the bowl 2 arrives on the tray 12 of the figure, the controller 32 controls the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com