Improved structure of peanut combine harvester

A combine harvester and harvester technology, applied to the improved structure of auger parts and conveying troughs, and in the field of picking and harvesting, it can solve problems such as difficult disassembly and assembly, machine operation stoppage, poor conveying, etc., to avoid complicated manufacturing process, Improved working speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

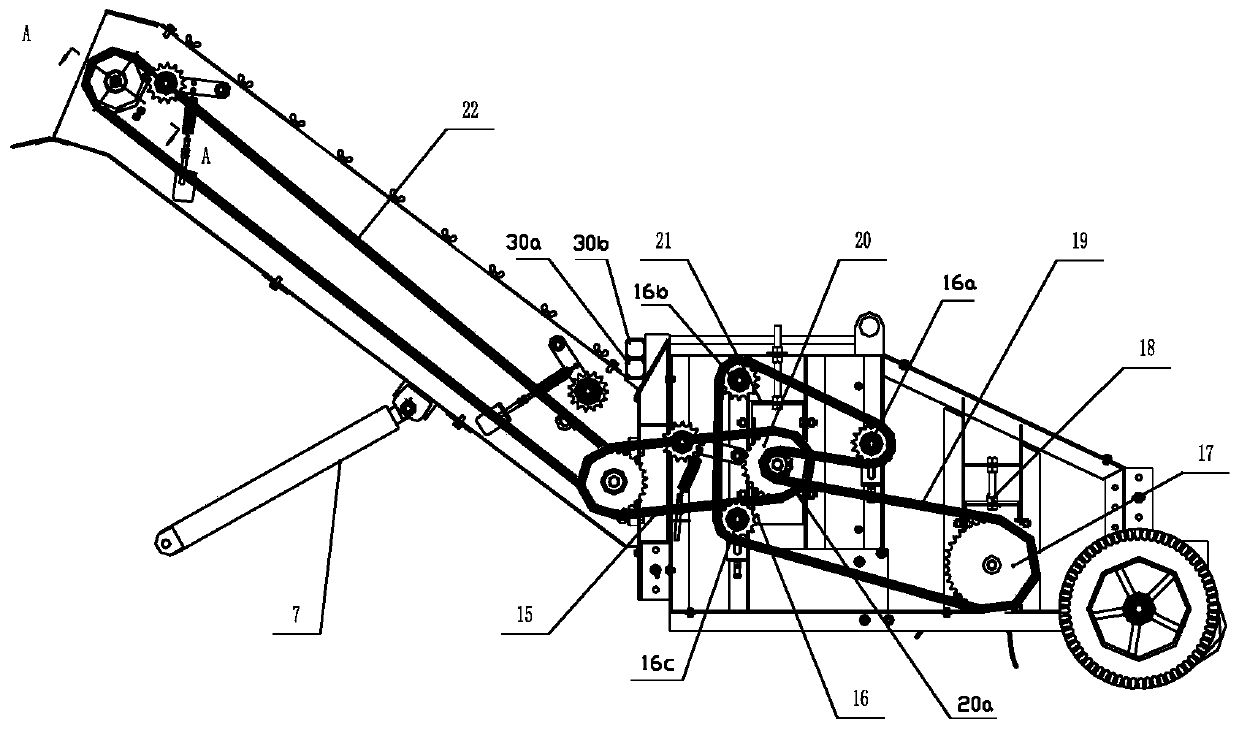

[0051] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0052] An improved structure of a peanut combine harvester. From the front of the harvester to the rear, there are semicircular seedling pressing rods 1 with openings upwards, protruding seedling sliding plates 3 and picking spring teeth 2 that rotate vertically, and then horizontally. The auger 5, the rear outlet of the auger 5 is connected to the conveying trough inclined upwards at the tail,

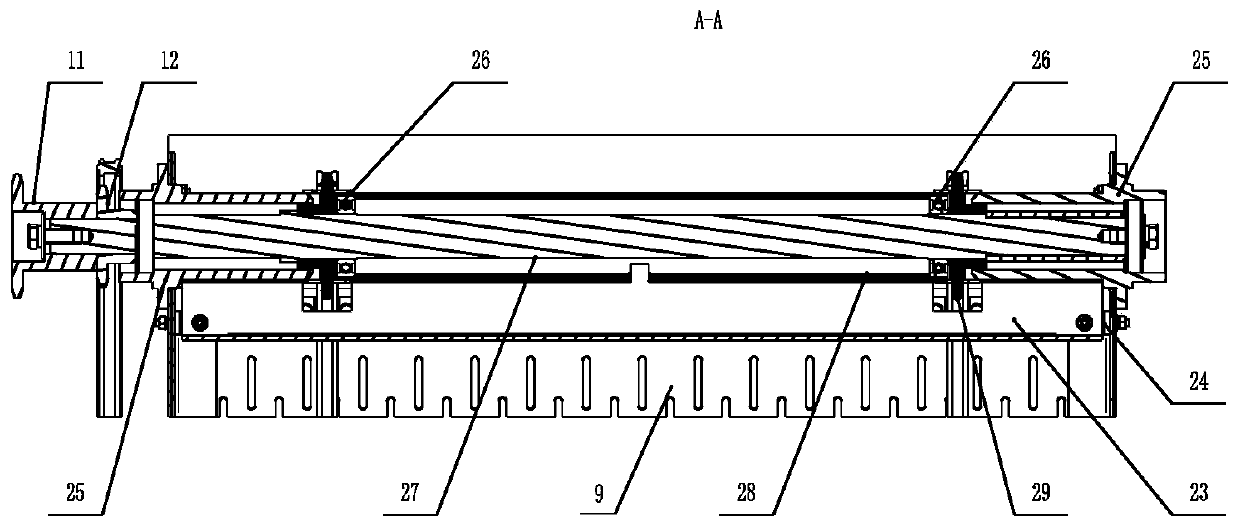

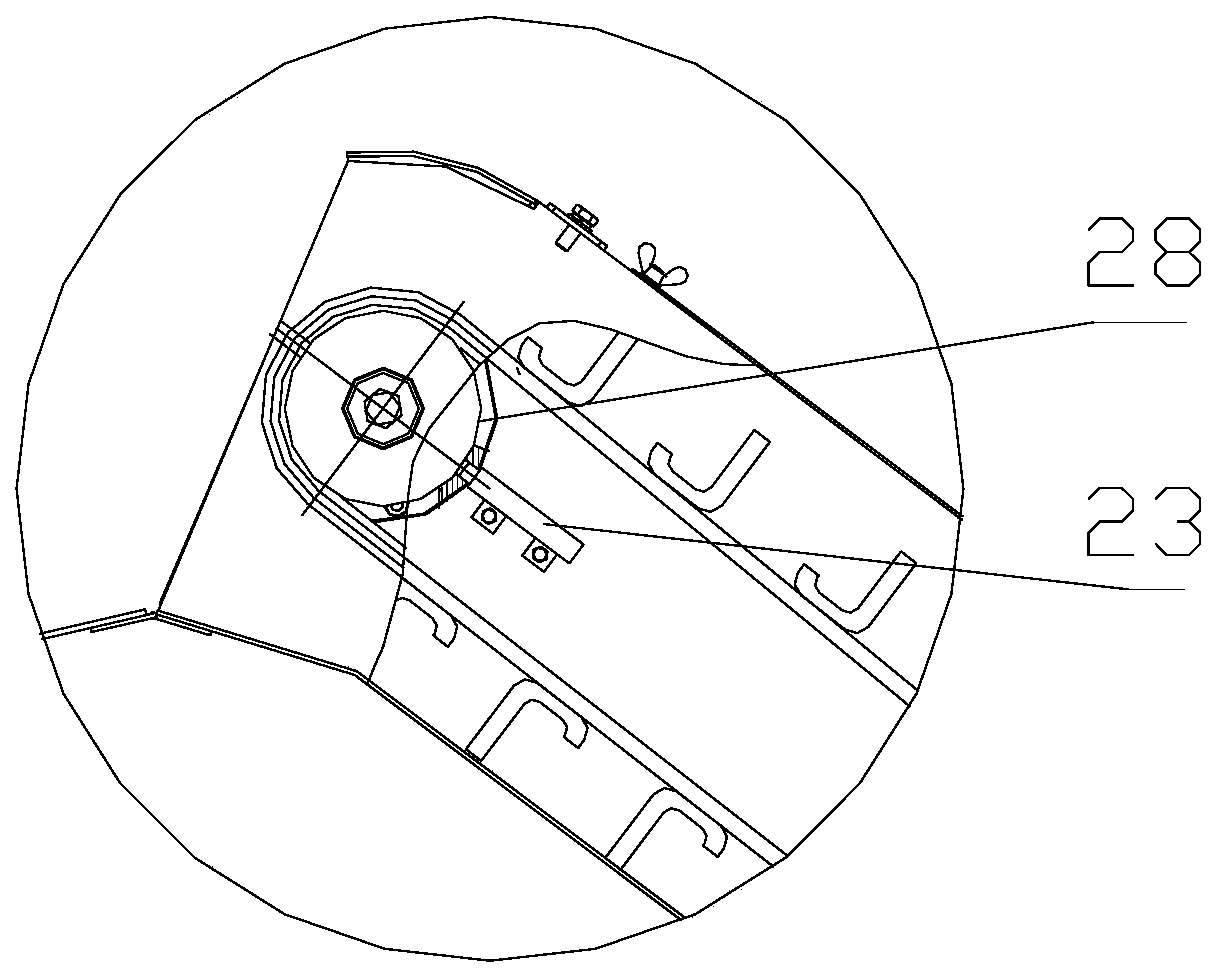

[0053] The tail part is obliquely upwards to form a flat rectangular conveying trough, and the front and rear parts are equipped with transmission shafts 27 horizontally and horizontally passing through the conveying trough shell. For the conveying trough sprocket 29, two pairs of conveying trough sprockets 29 are configured with two circulating conveying trough transmission chains 10, and a large number of horizontal scraper strips 8 are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com