Meat processing apparatus and meat processing method thereof

A meat processing and to-be-processed technology, applied in meat processing equipment, meat processing, slaughtering, etc., can solve the problems of simulated snowflake meat products that cannot be processed by natural snowflakes, and achieve rich meat varieties and cuts. Neat and taste-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

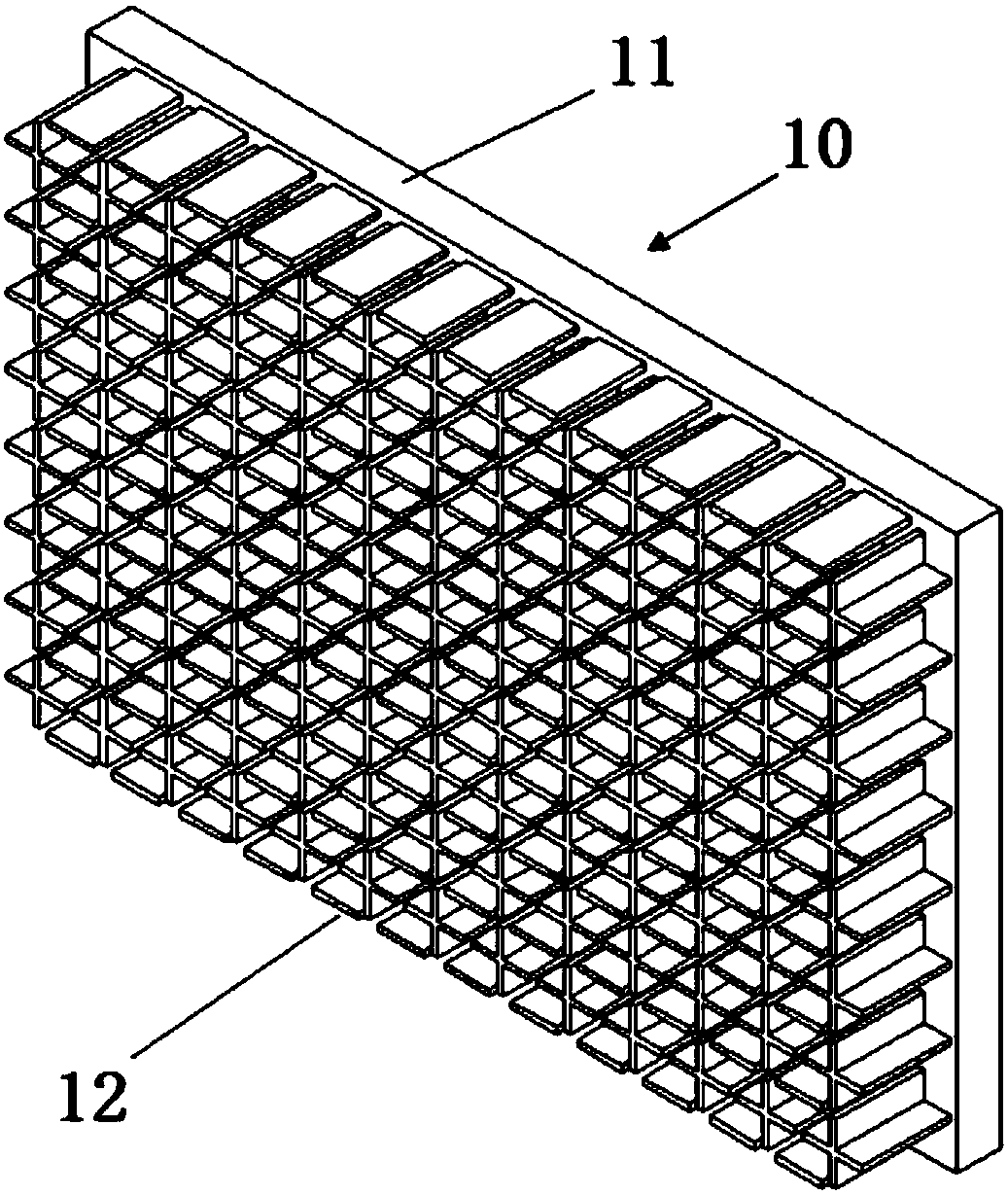

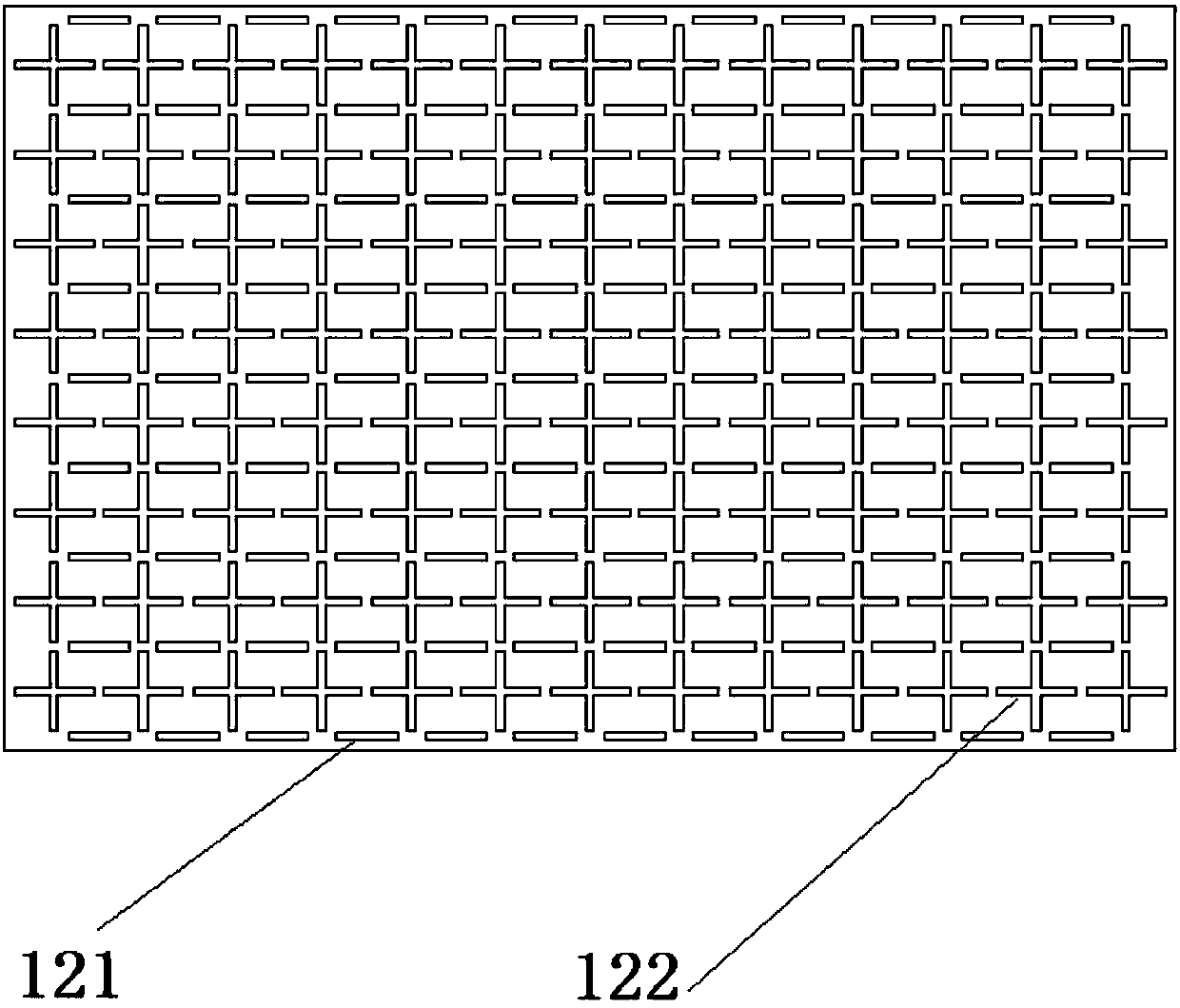

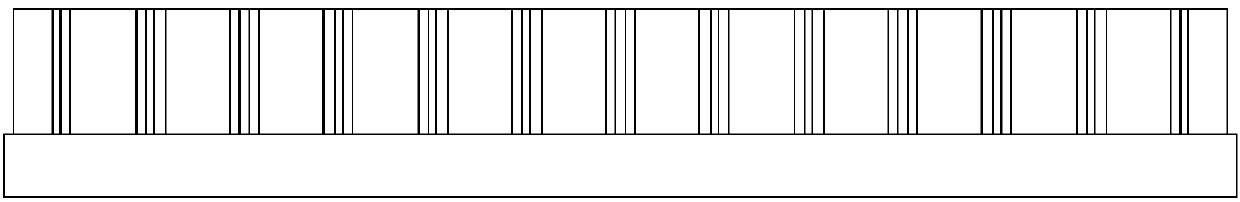

[0041] see Figure 1-4 , in which is shown a cutting element 10 of a meat processing device of the invention according to one embodiment of the invention. The base 11 of this cutting part 10 is a cuboid flat plate, and the cutting knife 12 comprises a cuboid cutting knife 121 and a cross-shaped cutting knife 122, and each cutting knife 12 is set independently, and many cuboid-shaped cutting knives 121 and many crosses The shape cutters 122 are arranged vertically and horizontally in a staggered manner. The cross-shaped cutter 122 can be regarded as two cuboid-shaped cutters 121 perpendicularly intersecting in the middle.

[0042] Preferably, the length of the rectangular flat plate is 5-30 cm, the width is 3-20 cm, and the thickness is 0.3 to 1 cm; more preferably, the length of the rectangular flat plate is 10-20 cm, the width is 5-15 cm, and the thickness is 0.5 to 0.8 centimeters; most preferably, the length of the cuboid flat plate is 15 centimeters, the width is 10 cent...

Embodiment 2

[0049] The meat processing device of this embodiment is basically the same as that of Embodiment 1 except that the base 11 of the cutting part 10 is a round roller, similar to that along the flat plate length direction of the cutting part 10 of the meat processing device of Embodiment 1. The edge is rolled into a circle, wherein the cutting knife 12 is perpendicular to the side of the round roll at 90°. The round roller-shaped base 11 of the cutting part 10 of the meat processing device facilitates rolling operation of the meat processing device.

[0050] The round roller-shaped meat processing device may not have cutters 12 arranged at the two ends of the roller, so that people's hands press the two ends and forcefully move the roller back and forth to cut an incision on the surface of the meat piece. Or, the middle part of the two bottom surfaces of the round rollers can be respectively connected to the smaller round rollers perpendicular to each bottom surface, so that the ...

Embodiment 3

[0053] This example is based on Example 1, using fatty meat slices to make simulated snowflake meat. Therefore, the meat processing device of this embodiment is the same as that of Embodiment 1, and the manner of making meat pieces with many cuts is similar.

[0054] Specifically, a piece of meat with many cuts is placed in the carrying part 20 of the meat processing device of the present invention, and then a piece of fat is placed on the piece of meat, passing through the pressing part 30 of the meat processing device extruding the fat so that at least some of the fat is extruded into the plurality of cuts, and then optionally removing the fat that is not extruded into the plurality of cuts, thereby obtaining fat in the plurality of cuts A mock snowflake of meat.

[0055] For the preparation of snowflake meat, the cuts of meat used are lean. Fat is squeezed into the many cuts in the lean cuts, creating red and white mock snowflakes. Of course, you can also do it the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com