Forging Forming Method of Irregular Cylinder

A cylinder and special-shaped technology, applied in the field of forging, can solve the problems of low utilization rate of parts material and time-consuming processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

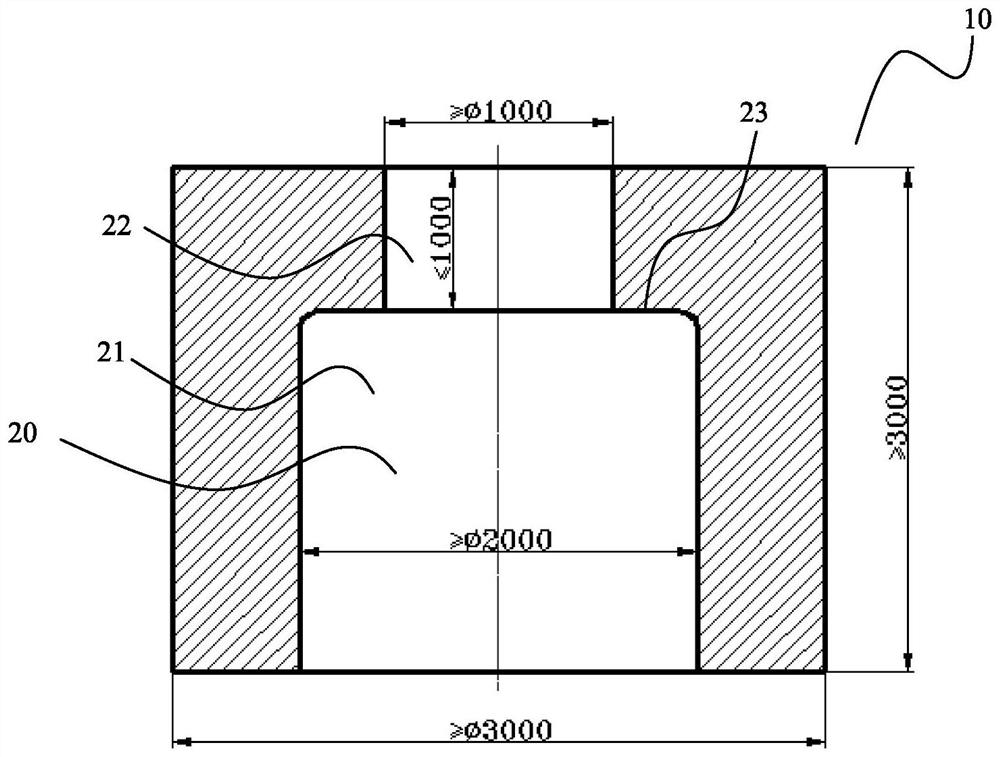

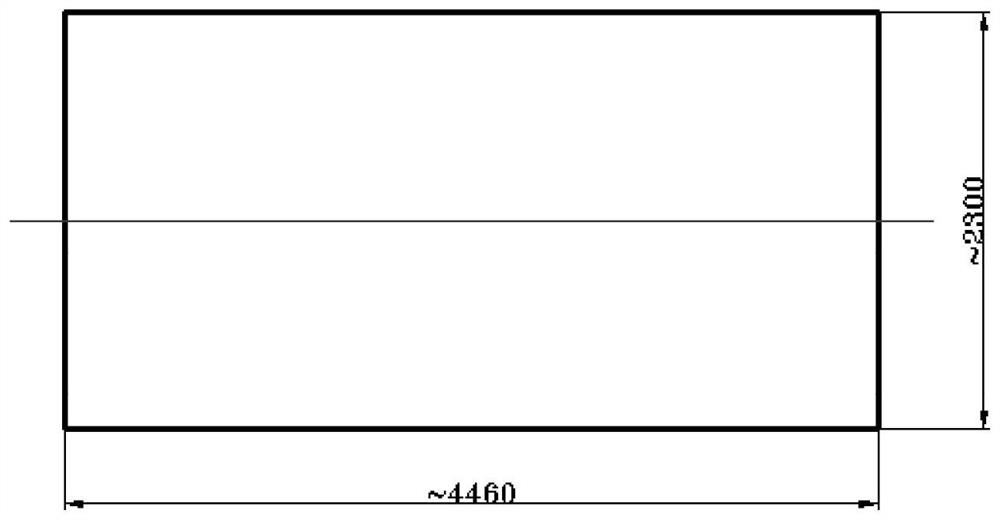

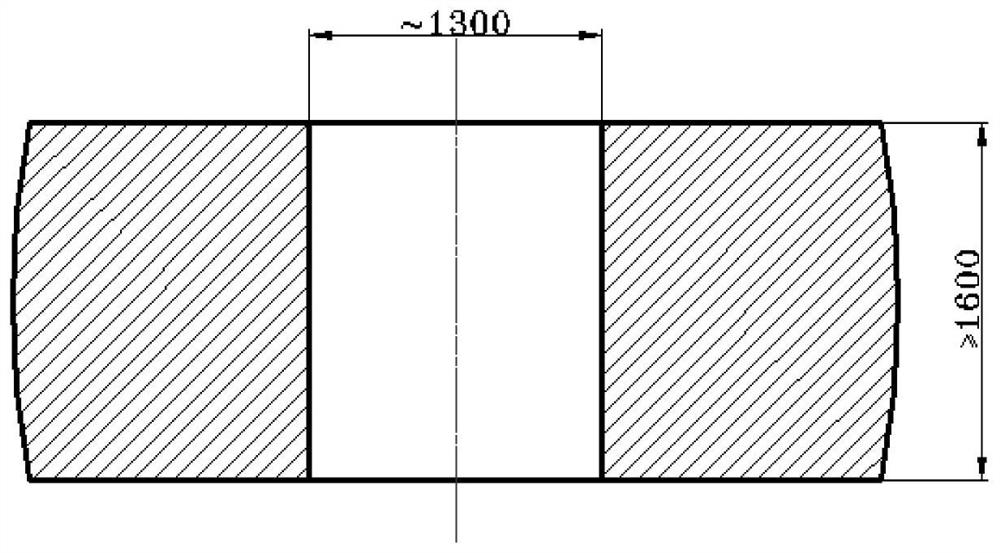

[0029] In the present invention, through the cooperation of 12,000-ton free forging hydraulic press and related tooling, through multiple free forging processes, the large double vacuum steel ingot is finally forged into a stepped cylinder with a large step difference at the end of the inner hole. The special-shaped cylindrical body 10 of the present invention final shaping is as figure 1 As shown, it has a cylindrical barrel, and a stepped inner hole 20 is formed inside. The stepped inner hole 20 has a cylindrical first hole body 21 and a second hole body 22. The diameter of the first hole body 21 is Greater than the diameter of the second hole 22, there is an annular hole step surface 23 between the first hole 21 and the second hole 22, and the axial length of the second hole 22 is less than or equal to one-third of the length of the entire cylinder. One; the width of the annular hole body step surface 23 is greater than the width of one-fifth of the diameter of the first ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com