Wire saw cutting machine and wire saw rotating control method

The technology of a saw cutting machine and a control method, which is applied to the field of wire saw cutting, can solve the problems that the cutting effect cannot be achieved, the direction and speed of the diamond wire rotation cannot be controlled, and the like, and the effect of improving the cutting effect can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

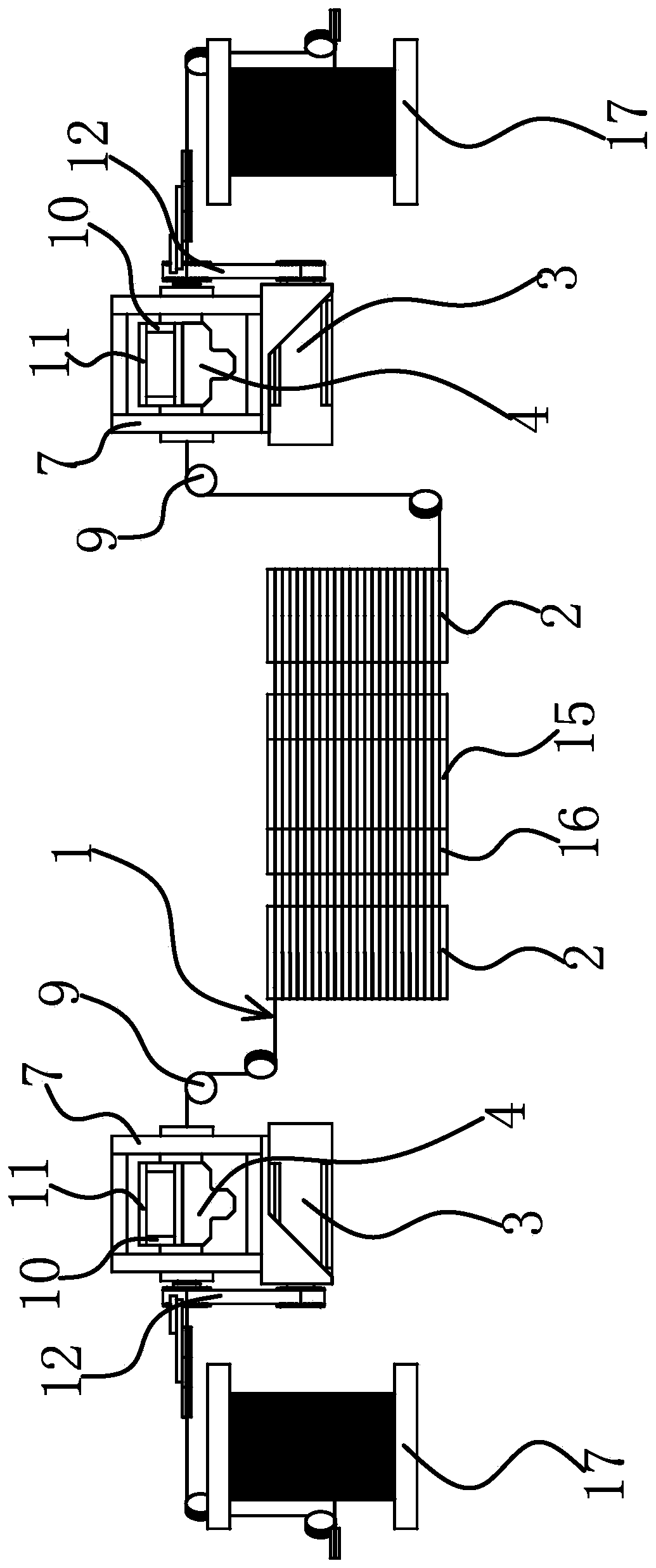

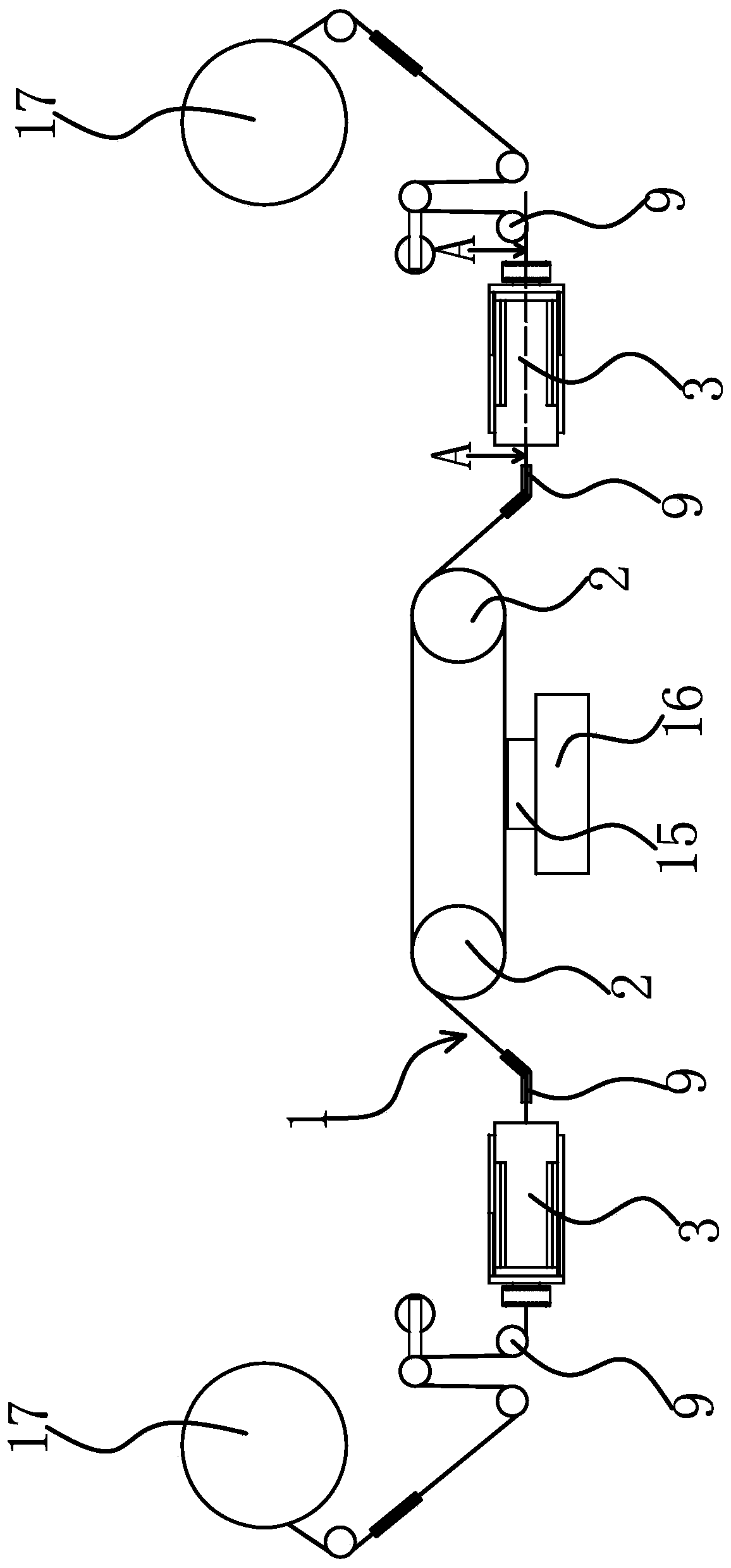

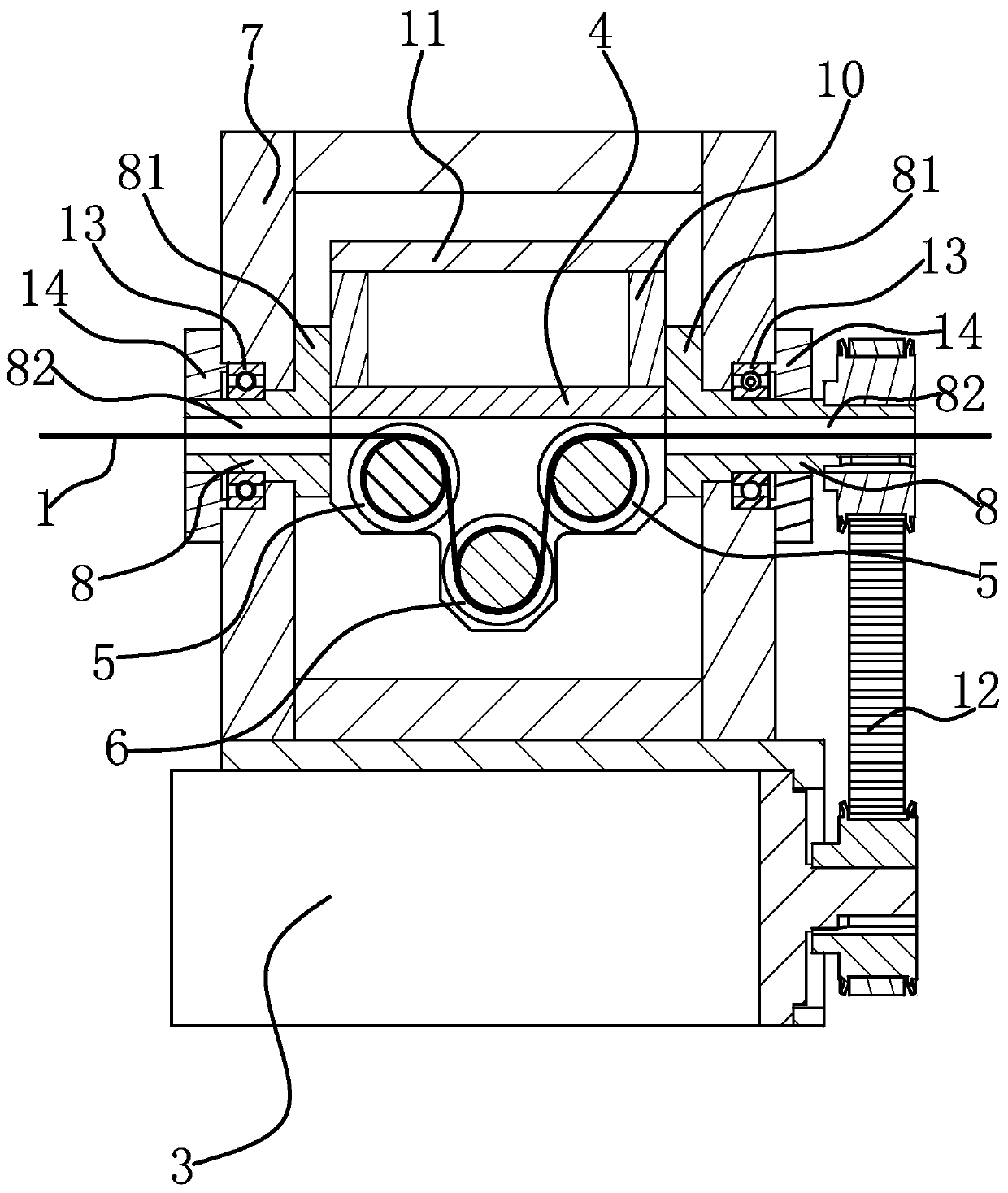

[0038] The wire saw cutting machine includes a wire saw 1, a guide roller 2, a driving motor 3, a rotating head 4, a limit roller 5 and a positioning roller 6.

[0039] Specifically, as figure 1 As shown, the two ends of the wire saw 1 are respectively wound on the barrel 17 , the middle part of the wire saw 1 is wound on the guide rollers 2 , and a parallel cutting area is formed between the guide rollers 2 . The workbench 16 is arranged at the position facing the cutting area, and the raw material 15 to be cut is fixed on the workbench 16 and can be fed to the cutting area under the drive of the workbench 16, so that the cutting area cuts the raw material 15. In the actual manufacturing process, the number of guide rollers 2 may be more than two, for example, the number of guide rollers 2 is three, and the three guide rollers 2 are arranged in a triangle.

[0040] In this example, if figure 1 with image 3 As shown, the number of guide rollers 2 is two, and the wire inlet...

Embodiment 2

[0045] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, such as Figure 5 As shown, the wire inlet side or the wire outlet side of the guide roller 2 is provided with a rotating head 4 that can rotate by itself driven by the drive motor 3 . The rotation of the wire saw 1 can also be realized by providing a swivel head 4 and transmits the rotation of the wire saw 1 to the cutting position.

Embodiment 3

[0047] The wire saw rotation control method in this embodiment is applied in a wire saw cutting machine in which the rotating head 4 drives the wire saw 1 to rotate, and the rotating head 4 is driven by the driving motor 3 .

[0048] The method for controlling the rotation of the wire saw includes the following steps:

[0049] Step a, determine the initial parameters according to the raw material 15 to be cut, the speed n 0 , the length of each row L 0 , cutting speed Vx, number of multi-wire saw rows m 0 , the number of wiring rows m;

[0050] Step b, Substituting the initial parameters into the formula to calculate the positive control parameters, the number of turns of the forward unit length line Change in the number of rotations in the positive direction Forward rotation time T α =m·L 0 / V x , where, in the above formula,

[0051] Step c, verify whether the wire saw 1 wears evenly in the circumferential direction when rotating forward, if Δα m > 1, then go to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com