A transmissive multi-alkali photocathode with wide spectral response and its manufacturing method

A technology of photocathode and manufacturing method, which is applied in the direction of luminescent cathode manufacturing, photoemission cathode, main electrode of discharge tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

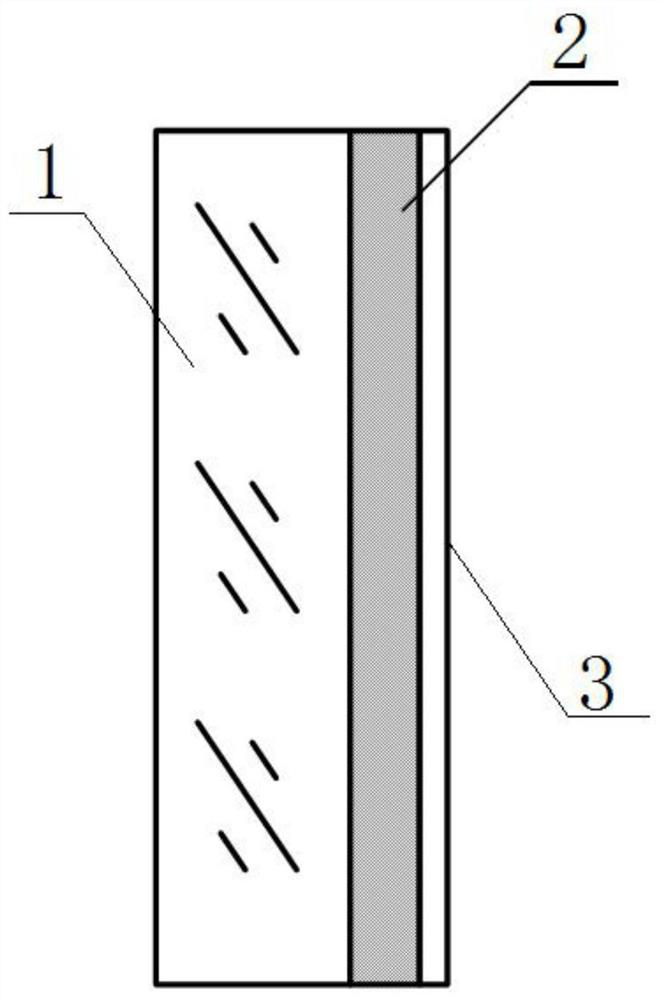

[0034] A non-imaging wide-spectrum response multi-alkali photocathode is manufactured by using a manufacturing method of a wide-spectrum response transmission-type multi-alkali photocathode proposed by the invention. For non-imaging vacuum photodetection devices, radial grids are used when making wide-spectrum response multi-alkali photocathode, see Figure 7 .

[0035] The manufacturing process of the broad-spectrum multi-alkali photocathode adopts the multi-alkali photocathode manufacturing process. The cathode glass window is made of synthetic quartz glass window, and the grade of the material is JGS1. The basic method is to put the cathode glass window, evaporation source K, Na, Cs and Sb, grid, etc. into the vacuum cavity of the cathode production equipment, and then vacuumize the vacuum cavity at 380°C with an oven. Bake for 12 hours. After high temperature baking, the vacuum degree of the vacuum chamber should not be lower than 10 -8 support. After the vacuum bakin...

Embodiment 2

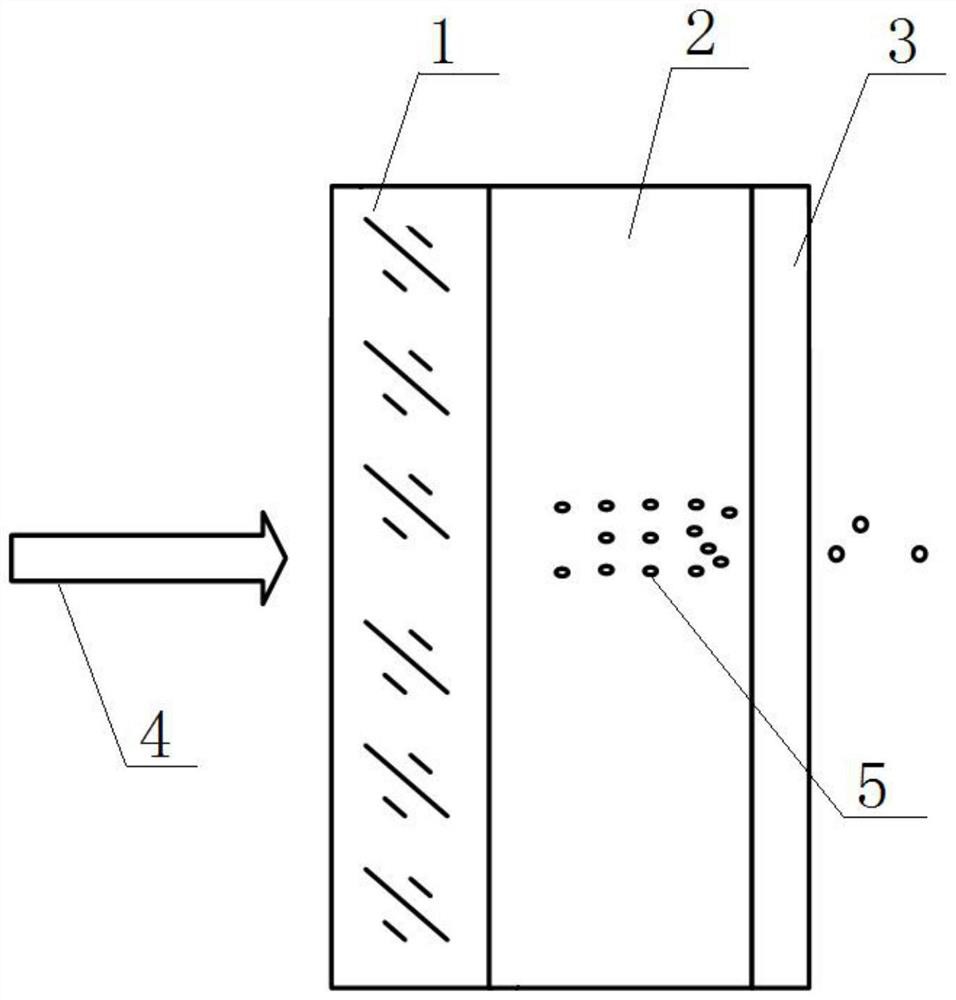

[0040] An image-type wide-spectrum response multi-alkali photocathode is fabricated by using a manufacturing method of a transmission-type multi-alkali photocathode with wide-spectrum response proposed by the invention. For imaging-type vacuum photodetection devices, square hole-shaped grids are used when making multi-alkali photocathode with wide spectral response, see Figure 8 . On the premise of the same duty cycle of the grid, the higher the density of the grid, the higher the resolution of the multi-alkali photocathode.

[0041] The manufacturing process of the broad-spectrum multi-alkali photocathode adopts the traditional multi-alkali photocathode manufacturing process. The cathode glass window is made of synthetic quartz glass window, and the grade of the material is JGS1. The basic method is to put the cathode glass window, evaporation source K, Na, Cs and Sb, grid, etc. into the vacuum cavity of the cathode production equipment, and then vacuumize the vacuum cavit...

Embodiment 3

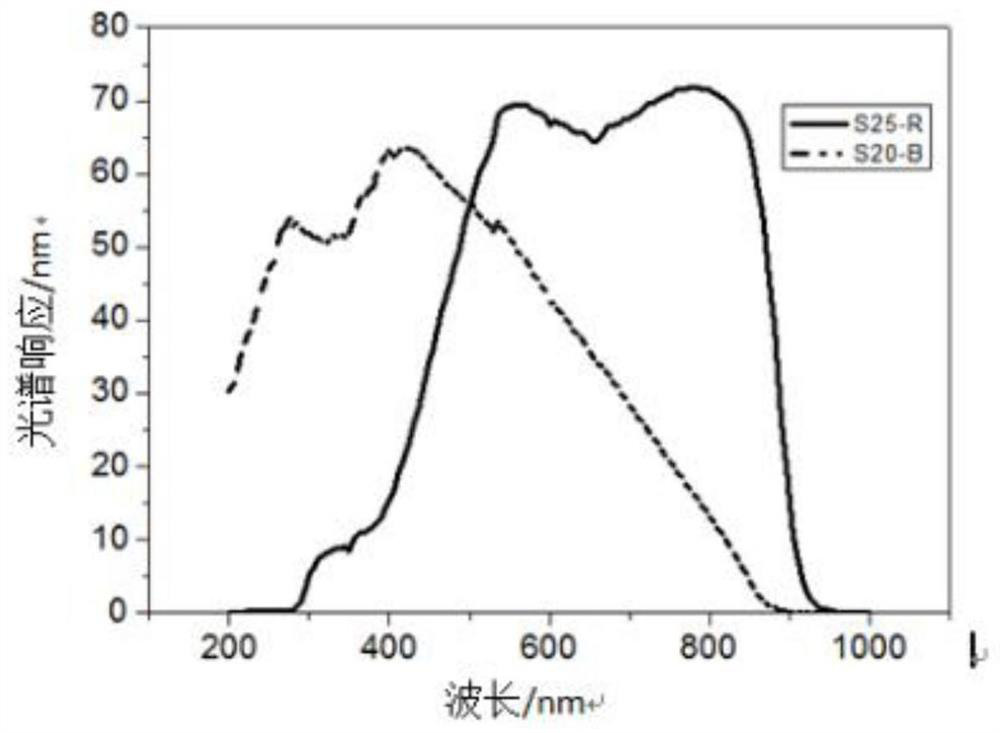

[0046] The schematic diagram of the surface structure of the multi-alkali photocathode made by the method of the present invention is shown in Figure 5 . From Figure 5 It can be seen that compared with the traditional multi-alkali photocathode, the surface of this multi-alkali photocathode is not flat, and the part blocked by the grid is thinner, which has the characteristics of the S20-B multi-alkali photocathode; The blocked part is thicker and has the characteristics of the S25-R multi-alkali photocathode. The thinner part can have a higher spectral response to ultraviolet light, while the thicker part has a higher spectral response to near-infrared light, so its spectral response is the superposition of the spectral response of thin multi-alkali photocathode and thick multi-alkali photocathode . The typical spectral response curves of the transmissive multi-alkali photocathode made by the method of the present invention are shown in Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com