Silicon dioxide compounded titanium dioxide catalyst for degrading coking wastewater as well as preparation method thereof

A technology of silicon dioxide and titanium dioxide, which is applied in the field of photocatalysis and sewage treatment, can solve the problems of high practical cost, lower photon efficiency, and low solar energy utilization rate, and achieve the effects of low cost, high catalytic activity, and accelerated degradation reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

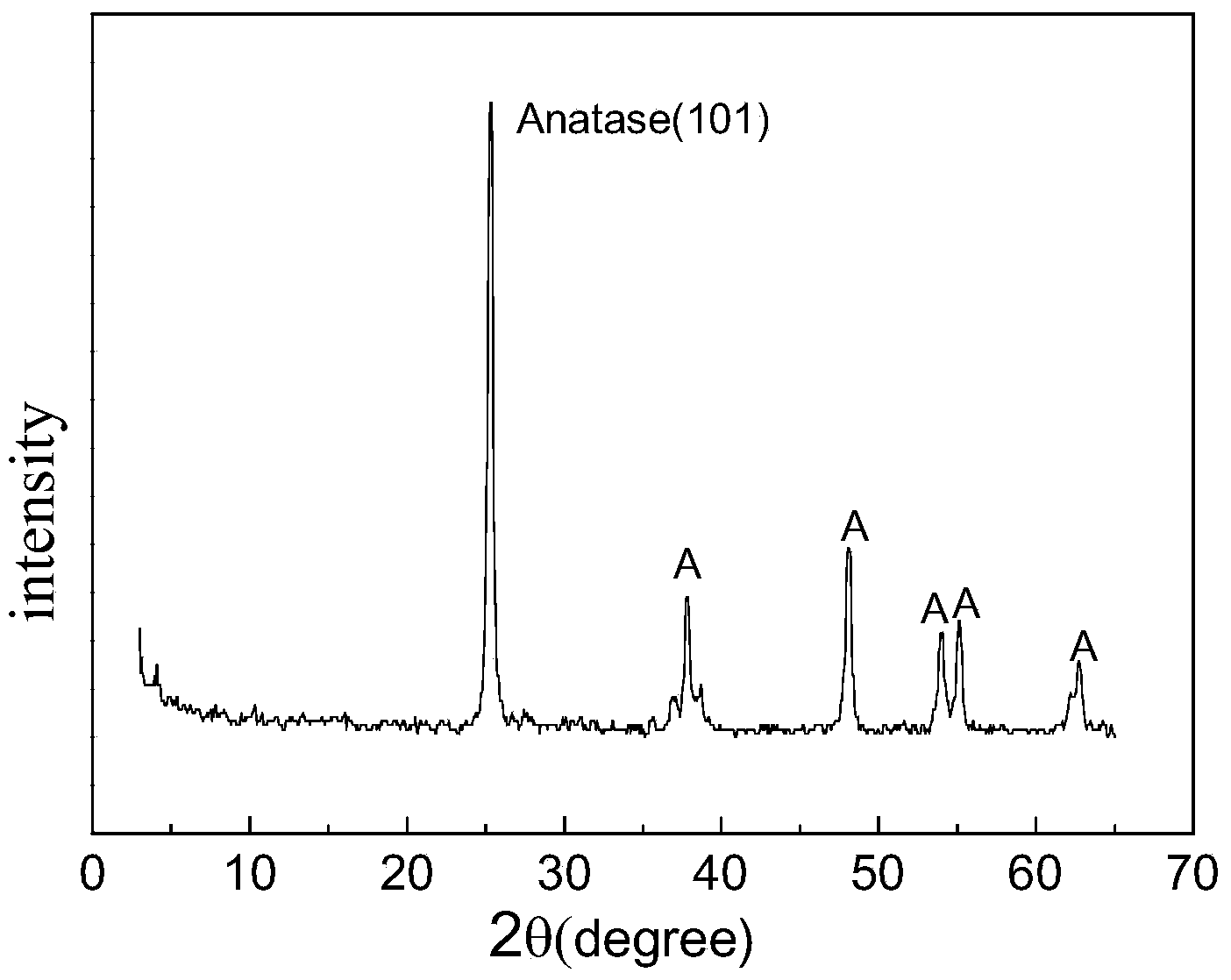

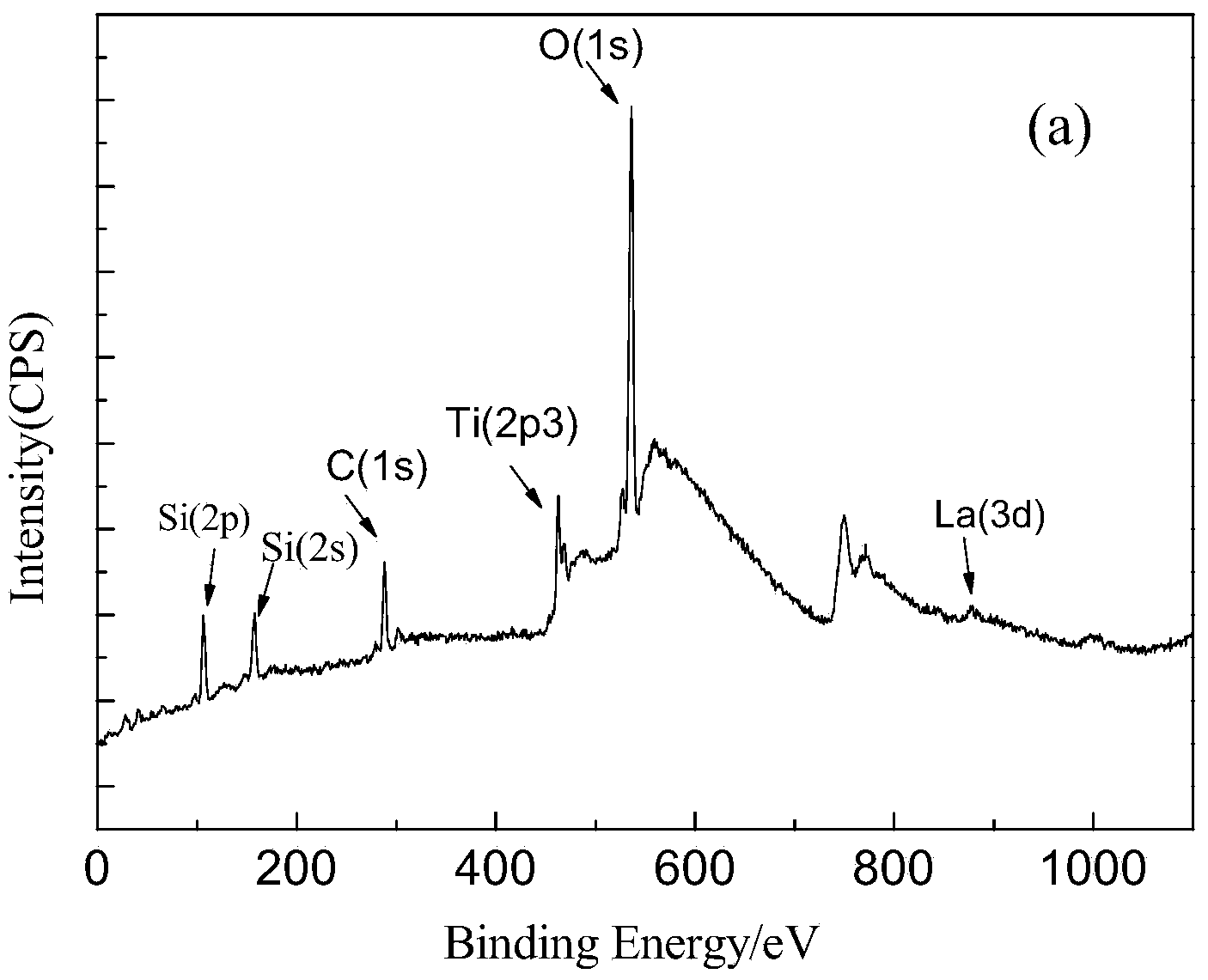

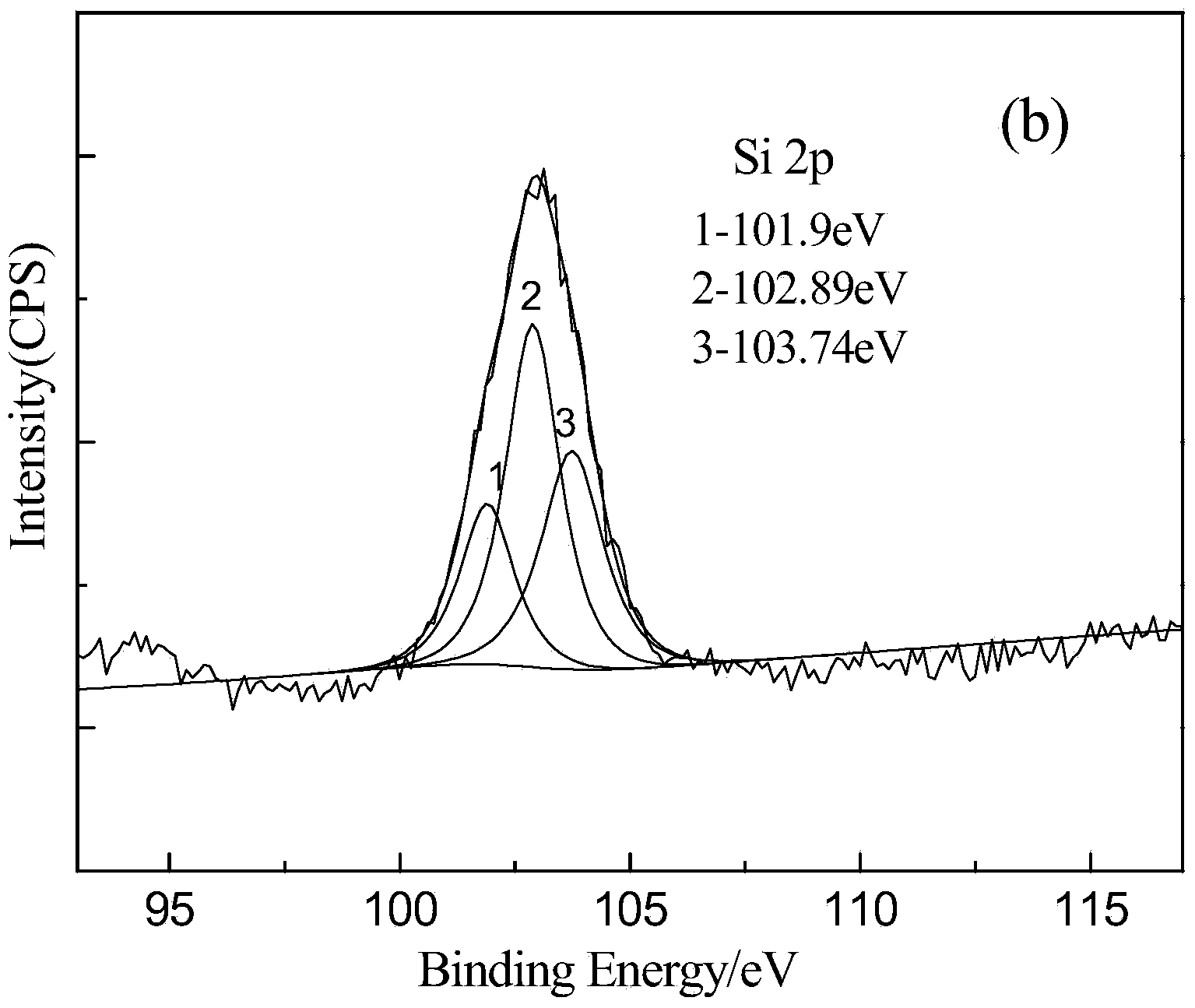

Method used

Image

Examples

Embodiment 1

[0040] The main pollutants of coking wastewater are phenolic compounds and ammonia nitrogen, and phenolic compounds account for more than 60% of the total organic components. Therefore, in this implementation case, phenol and ammonia nitrogen are respectively used as pollutants to prepare simulated wastewater with a certain mass concentration, and the photocatalyst oxidation technology is used for treatment. The photocatalyst is the modified titanium dioxide composite catalyst of the present invention.

[0041] The catalyst of this example is prepared according to the following preparation method: (1) Dissolve 27.2ml of butyl titanate in 190ml of absolute ethanol (the ratio of butyl titanate to absolute ethanol is 1:40), and use Mix well with a rapid mixer to obtain light yellow transparent solution A. (2) Weigh copper nitrate solid with copper content of 1% (the atomic percentage of copper and titanium in solution A), dissolve it in 500ml of water, and mix to obtain solution ...

Embodiment 2

[0044] On the basis of Example 1, the influence of pH is further considered. Change the pH value of the reaction solution (before the reaction, adjust the initial pH value of the solution with NaOH and HCl to be 2, 4.5, 7, 9.5, 10.5 respectively), the catalyst preparation method is the same as in Example 1, and the prepared catalyst and Silica catalyst was used for comparative test of wastewater treatment. When the catalyst dosage is 1.2g·L -1 , it has been shown from experiments that under strong acidity, the degradation rate of photocatalyst is very low, and the degradation rate of phenol is the best when the catalyst is around pH 7.5, which is the same as that without adding SiO 2 In contrast, the pH range of 4 ~ 7.5 composite nano-TiO 2 The photocatalytic activity of the photocatalyst increases, indicating that the addition of SiO 2 The optimal pH range of the final catalyst becomes larger, and it will be more adaptable to the subsequent wastewater treatment than the no...

Embodiment 3

[0046] The waste water in this example was taken from a coking plant in Guizhou. The raw water of the coking plant and the effluent of the secondary sedimentation tank were taken respectively. After passing the test, the water quality results are shown in Table 1.

[0047] Table 1 Main water quality indicators of coking plant wastewater

[0048]

[0049] The experimental device in this example is a photocatalytic reactor using a high-pressure mercury lamp (125W, 365nm) as a light source, and the catalyst prepared by the preparation method in Example 1 is used for reaction. The reaction solution is always stirred under the magnetic stirrer, so that the catalyst and the reaction solution are fully and uniformly mixed, and the reaction solution is continuously aerated to make the solution in an oxygen-saturated state. The reactor is not sealed, and samples are taken regularly for measurement. The composite catalyst is put into the reactor, the experimental method and condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com