A control method for a single-phase brushless motor

A single-phase brushless motor and control method technology, applied in the direction of single-phase motor control, etc., can solve the problems of high current peak value, current waveform distortion, poor performance of the whole machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further detailed below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are merely illustrative of the invention and are not limited thereto. It will also be also to be described, and only the parts associated with the present invention are shown in the drawings rather than all structures.

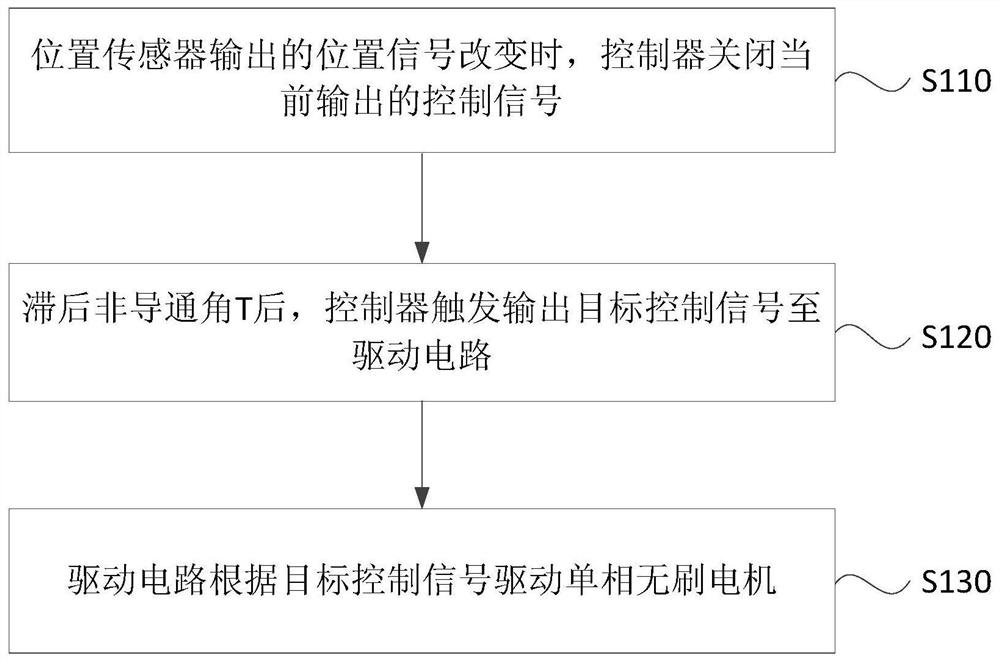

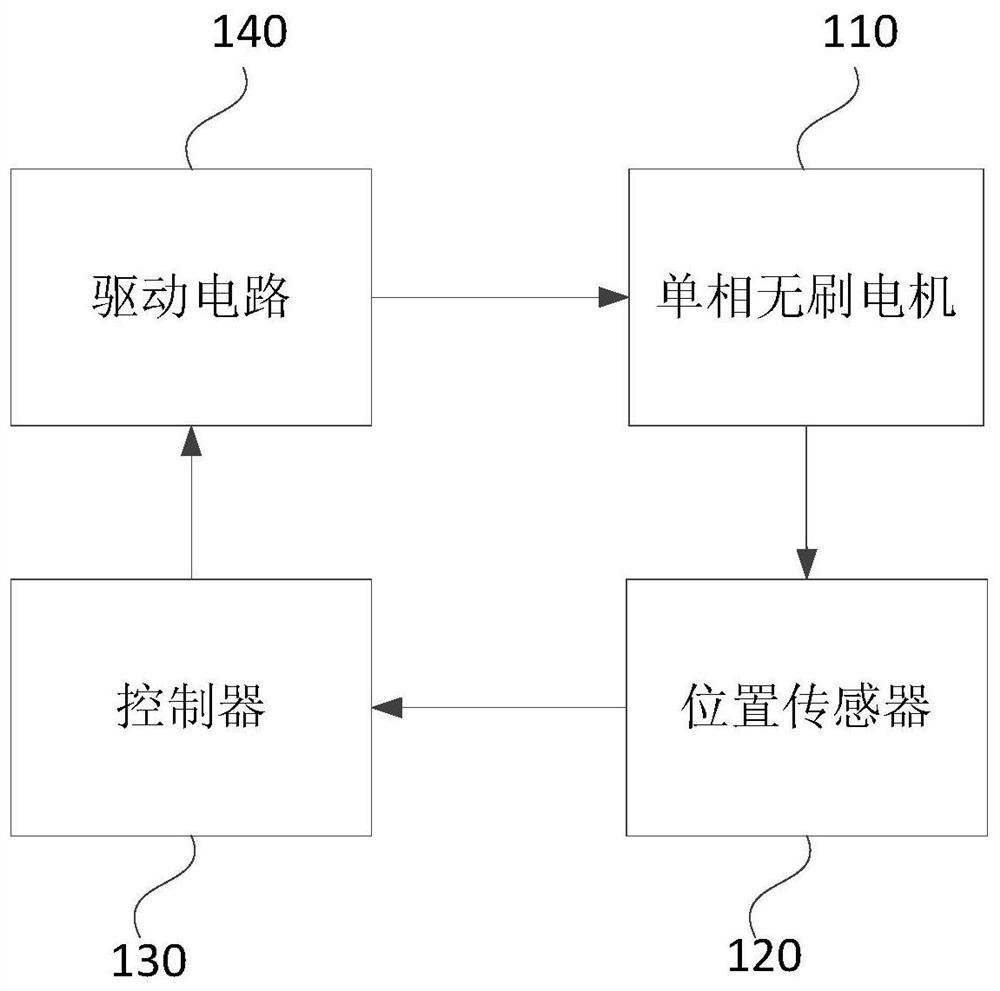

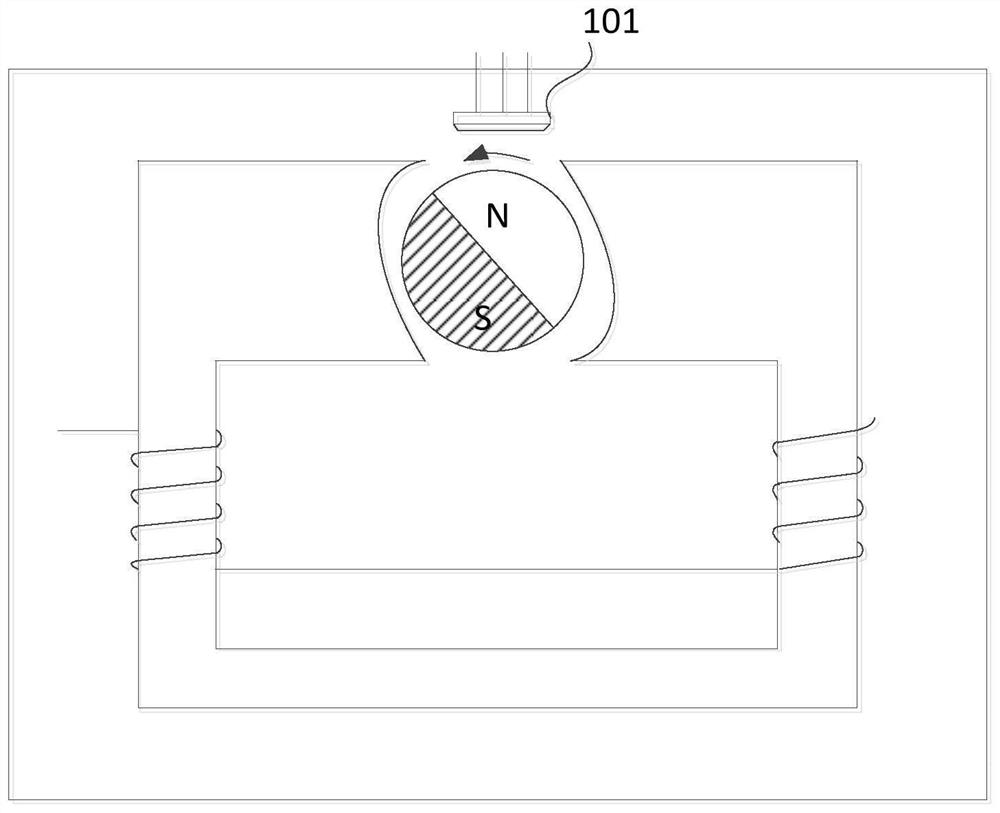

[0038] figure 1 A control flowchart of a method embodiment to provide a single-phase brushless motor of the embodiment of the present invention, the single-phase brushless motor may be used for electric power tool, the power tool includes a position sensor, a driving circuit and a controller; Illustratively, figure 2 System block diagram of a single-phase brushless motor provided in the embodiment of the present invention, see figure 2 The power tool may comprise a single-phase brushless motor 110, the position sensor 120, controller 130 and a driving circuit 140. The control method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com