Frequency conversion and constant current control method of LED drive system based on switched capacitor converter

A technology of LED driving and switched capacitors, which is applied in conversion equipment without intermediate conversion to AC, energy-saving control technology, electric light sources, etc., can solve the problem of unstable output voltage, narrow input voltage and output power range, dynamic switching capacitor converter Problems such as slow response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the drawings and specific embodiments.

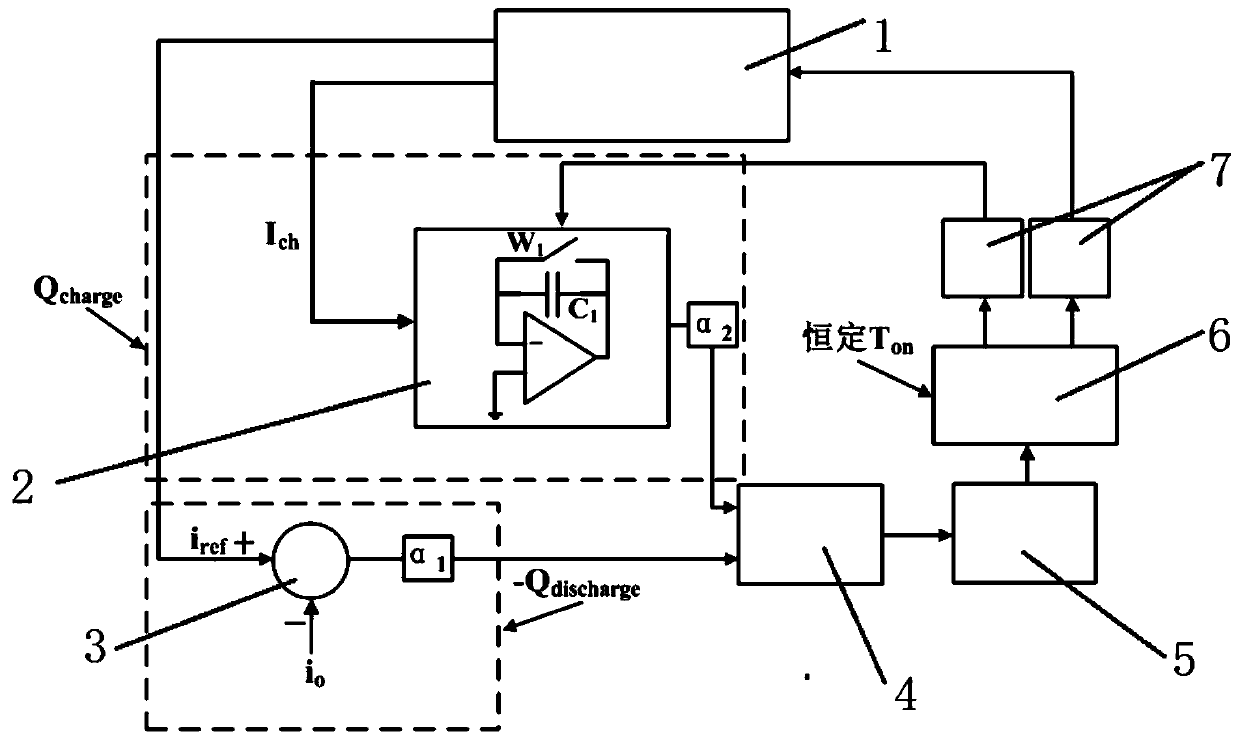

[0053] The present invention is based on the variable frequency constant current control method of the LED drive system of the switched capacitor converter, adopts the variable frequency constant current control system of the LED drive system based on the switched capacitor converter, such as figure 1 As shown, it includes an LED drive system 1 based on a switched capacitor converter. The LED drive system 1 based on a switched capacitor converter is connected with a resettable integrator 2 and an adder-subtractor 3, a resettable integrator 2 and an adder-subtractor 3 The signal output terminals are all connected to the signal input terminal of the comparator 4. The comparator 4 is connected to the D flip-flop 5 and the monostable multivibrator 6 in turn. The output terminals of the monostable multivibrator 6 are connected in parallel with two Output drive sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com