Fiber differentiation method

A fiber identification and fiber technology, which is used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high-level structure damage information of fibers, reduction, and unrealized identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

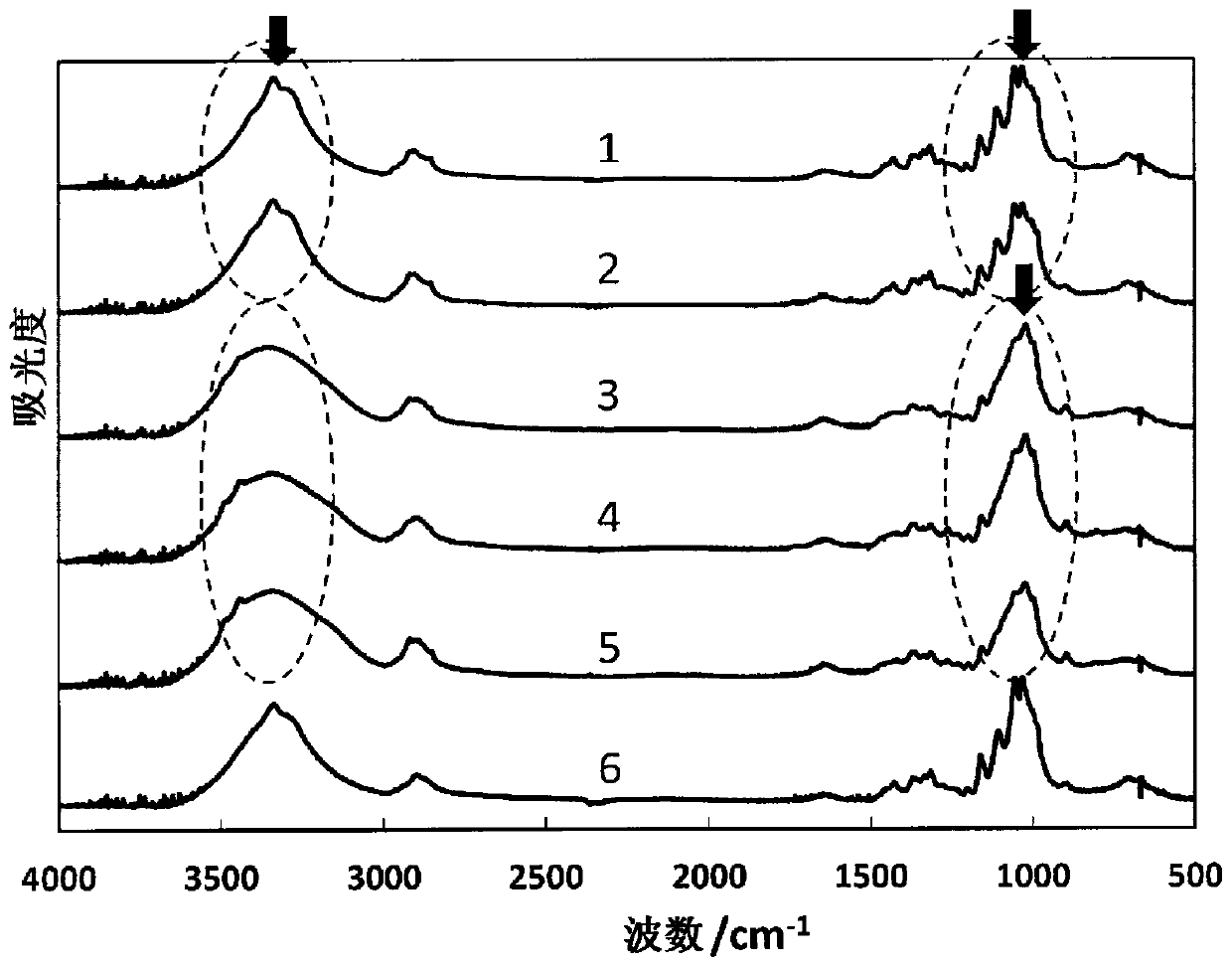

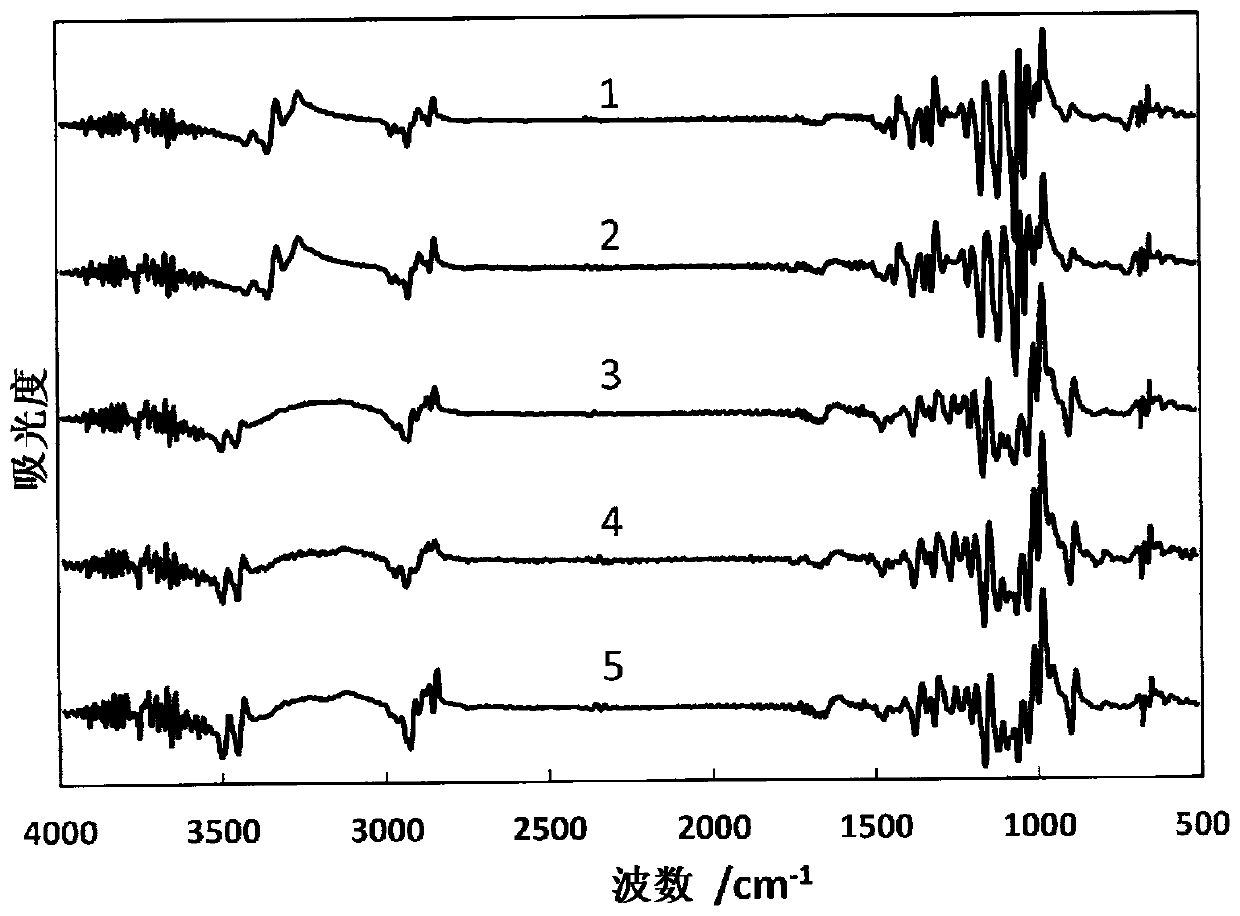

[0133] In the present first embodiment, discrimination between individual single fibers is performed for plural types of single fibers. For example, the identification of natural fibers and regenerated fibers in cellulose fibers, the identification of cotton and hemp, the identification of flax and ramie in hemp, the identification of regenerated fibers, and the identification of cupro ammonia silk and lyocell etc. for explanation. It should be noted that, in the first embodiment, discrimination is performed according to the degree of fitting of the score of the measured fiber to the equiprobable ellipse of the score of the discriminant model.

[0134] (1) Discriminant model preparation process

[0135] In the first embodiment, when performing identification of a combination of fibers to be identified, for example, cotton and hemp, these fibers are used as comparison fibers to obtain an absorption spectrum. It should be noted that various corrections can also be performed on...

Embodiment 1

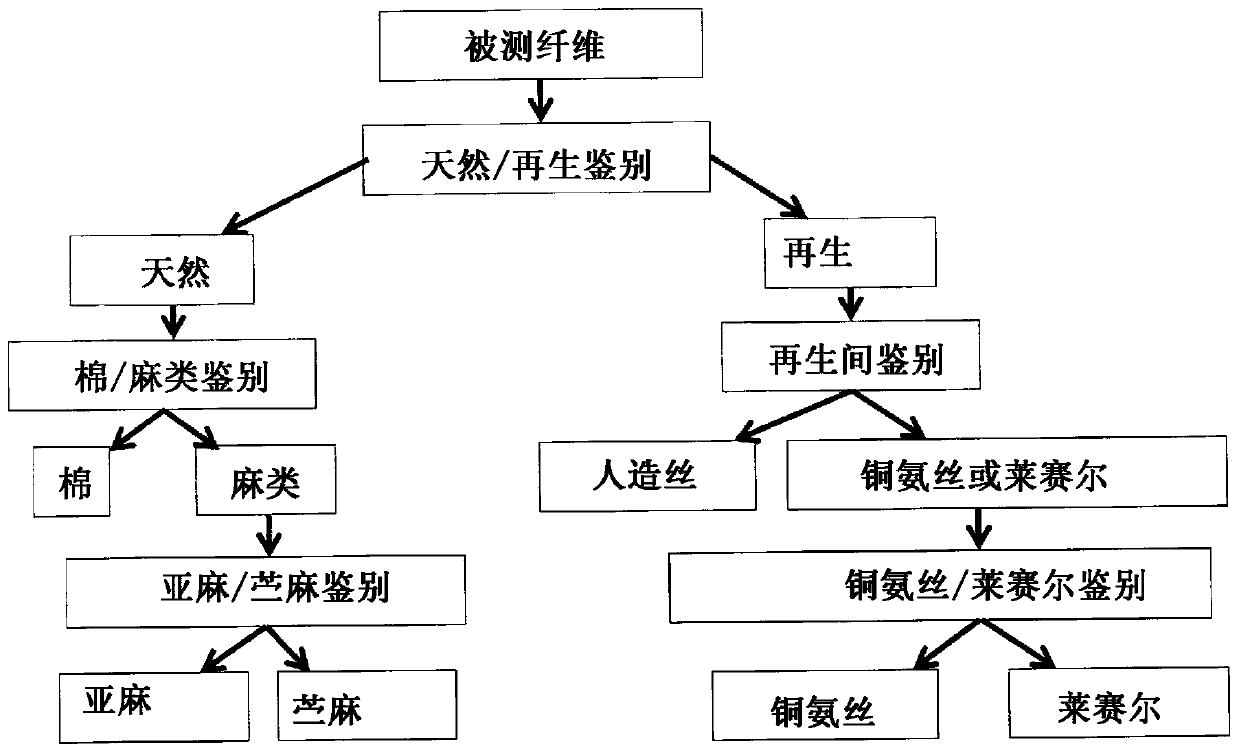

[0176] The present embodiment 1 carries out the discrimination between each single fiber of the above-mentioned first embodiment, according to the identification flow chart (referring to image 3 ) to identify multiple measured fibers. It should be noted that each fiber to be tested was confirmed to be cellulosic fiber in pre-identification such as microscopy.

[0177] (1) Discriminant model preparation process

[0178] In Example 1, first, 73 natural fibers including 27 cotton, 25 flax, and 21 ramie fibers were prepared as single fibers of known fiber types. In addition, 109 regenerated fibers including 48 rayon, 30 cupro, and 31 lyocell were prepared as single fibers whose fiber types are known. A total of 182 of these single fibers were used as comparative fibers in Example 1. In addition, 73 pieces of cotton and hemp (flax and ramie) and 40 pieces of some regenerated fibers (14 pieces of rayon, 13 pieces of cupro, and 13 pieces of lyocell) were used at room temperature....

no. 2 approach 》

[0240] In this second embodiment, as in the above-mentioned first embodiment, discrimination among individual fibers is performed for a plurality of types of individual fibers. For example, the identification of natural fibers and regenerated fibers in cellulose fibers, the identification of cotton and hemp, the identification of flax and ramie in hemp, the identification of regenerated fibers, and the identification of cupro ammonia silk and lyocell etc. for explanation. It should be noted that, in the second embodiment, the discrimination is performed based on the probability density of the normal distribution of the scores of the measured fibers with respect to the score group of the discriminant model.

[0241] (1) Discriminant model preparation process

[0242] Each operation of the discriminant model preparation step in the second embodiment is basically the same as that in the above-mentioned first embodiment. First, the absorption spectrum of each group of comparison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com