Method for monitoring flavor quality change of edible spices in cooking and application

A technology for spices and flavor substances, which is applied in the field of spice flavor quality monitoring, can solve problems such as undiscovered patent publications, and achieve the effect of improving flavor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 monitors the change of flavor quality of onion, ginger, garlic mixed system in cooking

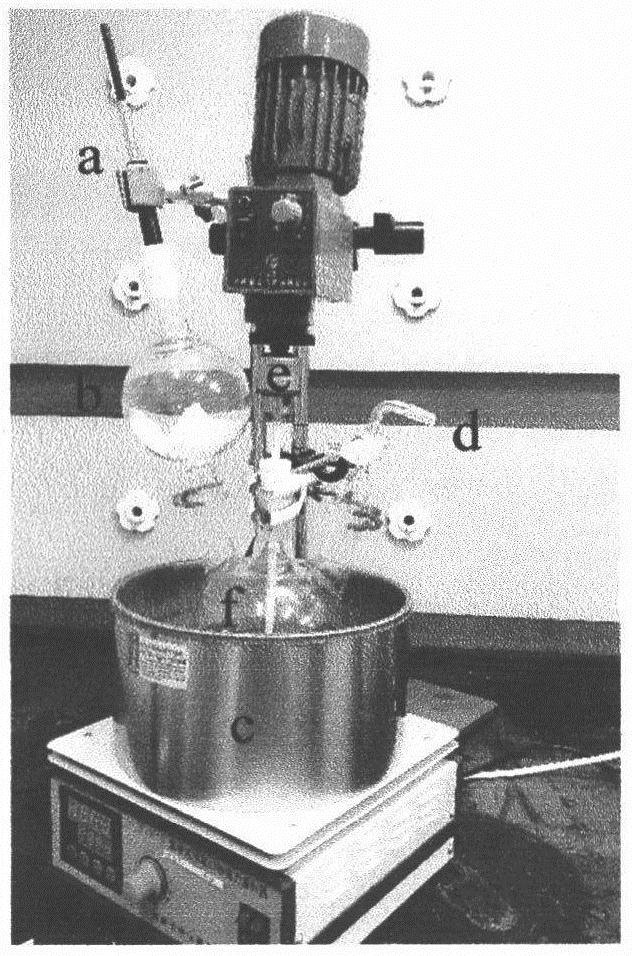

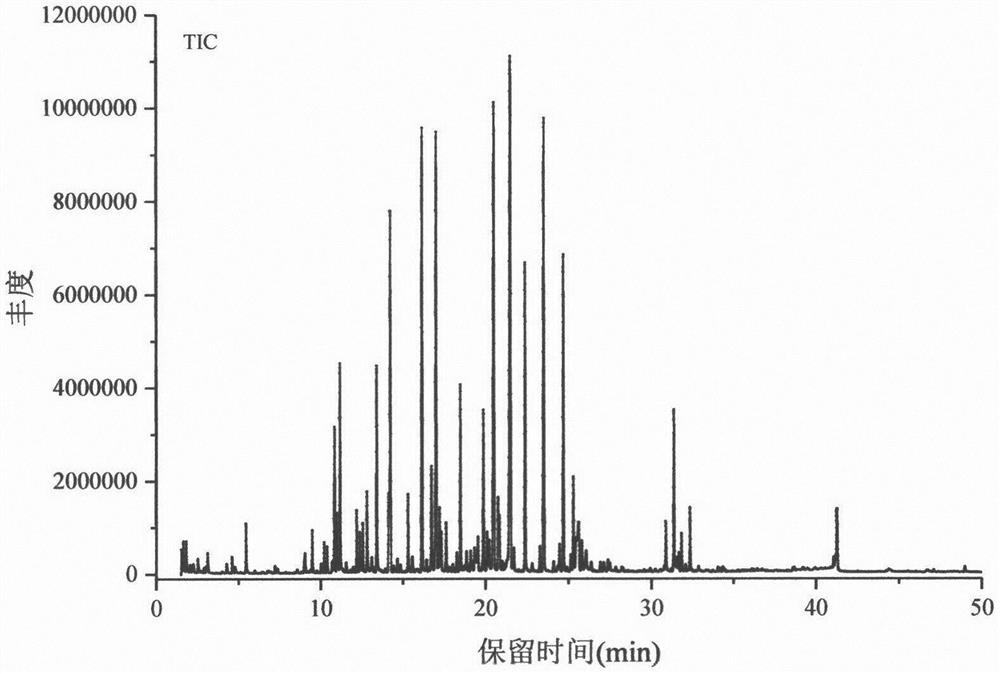

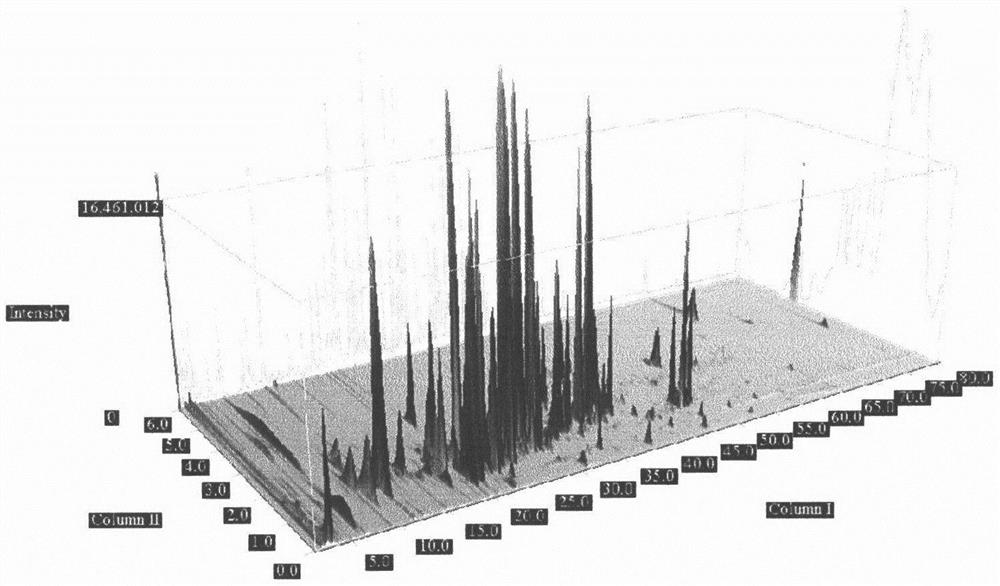

[0067] Pretreatment of onion, ginger and garlic. Peel the purchased fresh garlic, select garlic cloves of similar size and shape, and cut them into 1.5mm slices; wash fresh and mildew-free ginger, peel and cut into 1.5mm×1.5mm×20mm ginger strips; fresh Wash the green onions, remove the outer skin, and cut the white onion with a similar diameter into 2mm pieces. The bottom of the 1L flask was immersed in an oil bath, and the temperature of the oil bath was 155°C. Put 18 g of soybean oil into the flask, and wait until the soybean oil is heated up and the temperature is stable. Accurately weigh 3 g each of onion, ginger, and garlic into soybean oil, and time the adsorption for 30 min. Five groups are set in parallel for each test. The flavor acquisition conditions of the gas chromatography-mass spectrometer were as follows: the column program was initially 40 °C, held f...

Embodiment 2

[0070] Example 2 Monitoring the change of the flavor quality of Chinese prickly ash in cooking

[0071]Pick a pepper of similar shape and size, wash and air dry. The bottom of the 1L flask was immersed in an oil bath, and the temperature of the oil bath was 155°C. Put 18 g of soybean oil into the flask, and wait until the soybean oil is heated up and the temperature is stable. Accurately weigh 3 g of clean Zanthoxylum bungeanum into soybean oil, timed for adsorption for 30 min, and set five parallel groups for each test. The flavor acquisition conditions of the gas chromatography-mass spectrometer were as follows: the column program was initially 40 °C, held for 3 min, raised to 150 °C at 4 °C / min, held for 1 min, and then heated to 250 °C at 8 °C / min, held for 6 min; Injection port temperature: 250 °C; carrier gas: helium, flow rate of 1.00 mL / min; split injection. The mass spectrometry conditions were electron bombardment ion source, ion source (EI) temperature 200 °C, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com